Modified PET (Polyethylene Terephthalate) base material for heater and preparation method thereof

A heater and modification technology, applied in the field of engineering plastics, can solve the problems of poor insulation of heat dissipation materials, and achieve the effects of improving high temperature resistance and anti-aging ability, good insulation and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

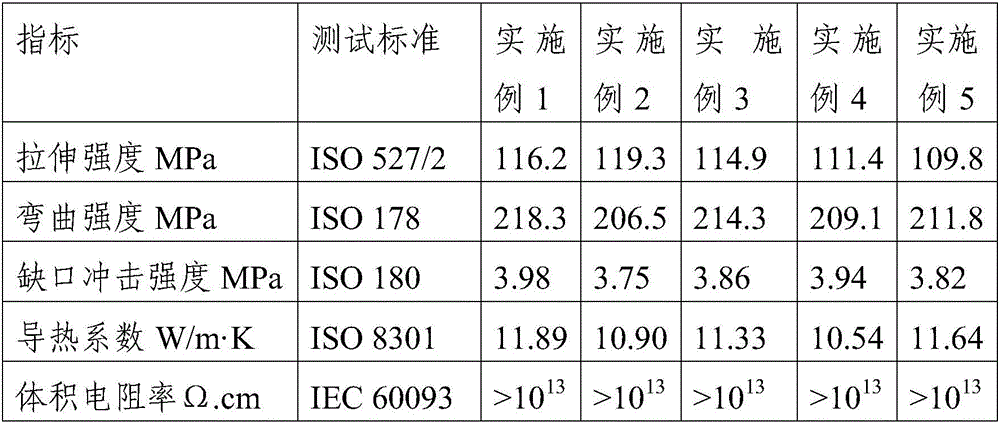

Examples

Embodiment 1

[0018] A modified PET base material for a heater, which is composed of the following raw materials in parts by weight: 65 parts of PET, 14 parts of modified nano-rectorite, 10 parts of polytetrafluoroethylene micropowder, 5 parts of glass fiber, 4 parts of aluminum nitride, 17 parts of zinc, 4 parts of nano-silicon nitride, 3 parts of aluminum oxide, 0.8 parts of talcum powder, 3 parts of dihydroxypolydimethylsiloxane, 3 parts of calcium-zinc composite stabilizer, 1.8 parts of barium stearate, ultraviolet absorption 0.4 parts of UV-P agent, 0.8 parts of hindered amine anti-aging agent, and 2 parts of toughening agent.

[0019] The preparation method of the modified nano-rectorite is as follows: adding a titanate coupling agent into the ethanol solution, adjusting the pH until the coupling agent is completely dissolved, then adding the modified nano-rectorite into it, stirring thoroughly and then Ultrasonic dispersion is carried out, and the spray drying method is used to dry i...

Embodiment 2

[0025] A modified PET base material for a heater, which is composed of the following raw materials in parts by weight: 70 parts of PET, 12 parts of modified nano-rectorite, 12 parts of polytetrafluoroethylene micropowder, 4 parts of glass fiber, 6 parts of aluminum nitride, oxide 15 parts of zinc, 5 parts of nano-silicon nitride, 2 parts of aluminum oxide, 01 parts of talc powder, 2 parts of dihydroxypolydimethylsiloxane, 4 parts of calcium zinc composite stabilizer, 1.5 parts of barium stearate, ultraviolet absorption 0.4 parts of UV-9 agent, 0.8 parts of benzophenone anti-aging agent, and 3 parts of toughening agent.

[0026] The preparation method of the modified nano-rectorite is as follows: adding a silane coupling agent to the ethanol solution, adjusting the pH until the coupling agent is completely dissolved, then adding the modified nano-rectorite to it, and then performing ultrasonication after fully stirring. Disperse and dry it by spray drying, so that the surface o...

Embodiment 3

[0033] A modified PET base material for a heater, which is composed of the following raw materials in parts by weight: 60 parts of PET, 16 parts of modified nano-rectorite, 8 parts of polytetrafluoroethylene micropowder, 6 parts of glass fiber, 3 parts of aluminum nitride, oxide 18 parts of zinc, 3 parts of nano-silicon nitride, 4 parts of aluminum oxide, 0.5 parts of talcum powder, 4 parts of dihydroxypolydimethylsiloxane, 2 parts of calcium-zinc composite stabilizer, 2 parts of barium stearate, ultraviolet absorption UV-P 0.3 part, hindered amine anti-aging agent 0.5 part, benzophenone anti-aging agent 0.5 part, toughening agent 1 part.

[0034] The preparation method of the modified nano-rectorite is as follows: adding an aluminate coupling agent into an ethanol solution, adjusting the pH until the coupling agent is completely dissolved, then adding the modified nano-rectorite into it, stirring thoroughly and then Ultrasonic dispersion is carried out, and the spray drying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com