Aluminum-alloy anticorrosion coating and preparing method and application thereof

A technology for anti-corrosion coatings and aluminum alloys, applied in the field of metal protective coatings and aluminum alloy anti-corrosion coatings, can solve the problems of poor coating compactness, poor adhesion between coatings and aluminum alloys, easy to fall off, etc., to achieve good adhesion and comprehensive Excellent anti-corrosion performance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

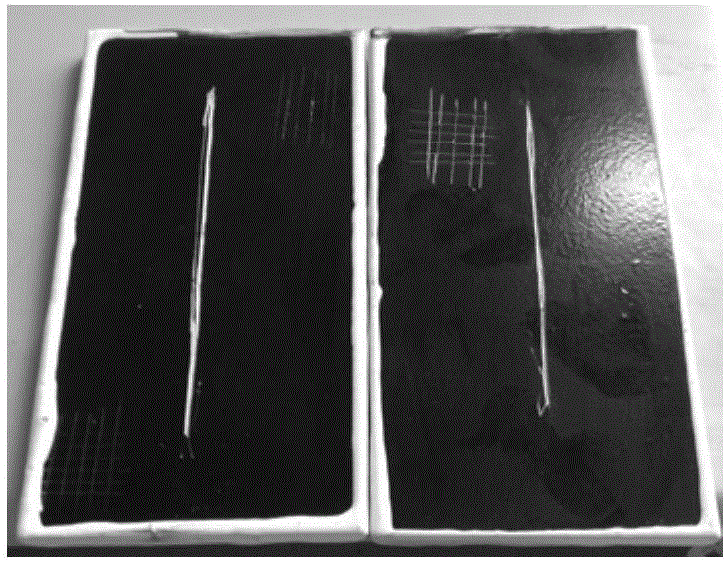

Embodiment 1

[0052] Disperse 0.2g pyrogallol and 0.8g graphene (purchased from Ningbo Moxi Technology Co., Ltd., the number of graphene layers is about 6-8 layers) in 20mL n-butanol, stir at 1500r / min for 30min, and then add 6g titanium dioxide, 15g talcum powder, stir, add the prepared dispersion slurry to 20g epoxy resin E20 (purchased from Shandong Deyuan Epoxy Technology Co., Ltd.), add 10g strontium chrome yellow (purchased from Shanghai Chrome Yellow Pigment Factory) successively Suzhou branch), 8g zinc phosphate (purchased from Shanghai Longbo Chemical Co., Ltd.), 15mL xylene, 1g polyamide wax, 1g bentonite, 0.5g leveling agent BYK392, stirred at 1000r / min for 20min, then added 10g cardanol The curing agent (purchased from Wuxi Guangming Chemical Co., Ltd.) was stirred evenly to obtain an aluminum alloy anti-corrosion coating. The adhesion, flexibility, salt spray resistance and salt water immersion resistance of the coating formed by it are shown in Table 1. The coated aluminum all...

Embodiment 2

[0054] Disperse 0.1g Triton X100, 0.1g benzyl alcohol and 0.7g graphene (purchased from Ningbo Moxi Technology Co., Ltd., the number of graphene layers is about 6-8 layers) in 30mL n-butanol, and stir at 1500r / min 30min, then add 10g titanium dioxide successively, 15g talcum powder, stir, add the prepared dispersion slurry in 20g epoxy resin E44 (purchased from Shandong Deyuan Epoxy Technology Co., Ltd.), add successively 15g strontium chrome yellow (purchased from Shanghai Chrome Yellow Pigment Factory Suzhou Branch), 8g zinc phosphate (purchased from Shanghai Longbo Chemical Co., Ltd.), 15mL xylene, 1g polyamide wax, 0.5g bentonite, 0.6g leveling agent BYK392, 1000r / min stirring for 20min , then add 12g of polyamide curing agent DF1228 (purchased from Shandong Deyuan Epoxy Technology Co., Ltd.), and stir evenly to obtain an aluminum alloy anti-corrosion coating. The adhesion, flexibility, salt spray resistance and The resistance to salt water immersion is shown in Table 1. ...

Embodiment 3

[0056] Disperse 0.2g pyrogallol and 0.8g graphene (purchased from Ningbo Moxi Technology Co., Ltd., the number of graphene layers is 6-8 layers) in 20mL n-butanol, stir at 1500r / min for 30min, and then add 8g Titanium dioxide, 12g talcum powder, stirring, the prepared dispersion slurry is added to 20g epoxy resin (purchased from Shandong Deyuan Epoxy Technology Co., Ltd.), and 10g strontium chrome yellow (purchased from Shanghai Chrome Yellow Pigment Factory, Suzhou, China) is added successively. branch), 8g zinc phosphate (purchased from Shanghai Longbo Chemical Co., Ltd.), 15mL xylene, 2g polyamide wax, 0.5g leveling agent BYK392, stirred at 1000r / min for 20min, then added 10g cardanol curing agent (purchased from Wuxi Guangming Chemical Co., Ltd.) and stir evenly to obtain an aluminum alloy anti-corrosion coating. The adhesion, flexibility, salt spray resistance and salt water immersion resistance of the coating formed by it are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com