A kind of preparation method of α-galactosidase with low content of β-mannosidase

A technology of mannosidase and galactosidase, applied in the field of preparation of α-galactosidase, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of galactomannooligosaccharide comprises the following steps:

[0025] (1) Add 20-100 mesh S. japonica seeds into the enzymolysis bottle, add β-mannanase according to the enzyme dosage of 20U / g galactomannan, add 1M citric acid buffer, distilled water, and mix well , the concentration of galactomannan in the reaction system is 20g / L, the initial pH value is 4.80, and it is placed in a constant temperature shaker at 50°C and 150 rpm for enzymatic hydrolysis for 12h. Under treatment for 10 min, centrifuged at 10,000 rpm for 10 min, the supernatant is the enzymatic hydrolyzed supernatant containing galactomannooligosaccharide.

[0026] (2) Take the galactomanno-oligosaccharide-containing enzymatic hydrolysis clear liquid obtained in step (1), add absolute ethanol under stirring conditions, make the ethanol concentration in the system be 65% (v / v), at 10000 rpm / Centrifuge under different conditions for 10 min to obtain supernatant and precipitate. ...

Embodiment 2

[0030] Trichoderma reesei uses galactomannooligosaccharide as carbon source to ferment and produce enzymes, including the following steps:

[0031] (1) Enzyme production medium (g / L): galactomannooligosaccharide 10.0 (prepared in Example 1), glucose 1.0, potassium dihydrogen phosphate 2.0, magnesium sulfate heptahydrate 0.08, ferrous sulfate heptahydrate 0.005, a Manganese sulfate water 0.0016, zinc sulfate heptahydrate 0.0014, cobalt chloride 0.0037. The medium was adjusted to pH 4.8 with 1 M citrate buffer.

[0032] (2) Fermentation to produce enzymes

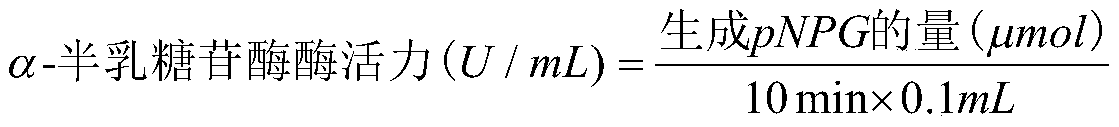

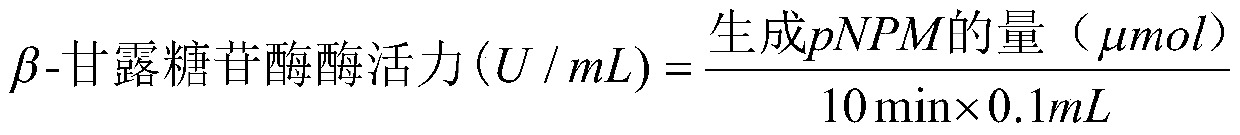

[0033] 50 mL of culture medium was placed in a 250 mL conical flask with a cotton stopper, inoculated with Trichoderma reesei seeds at 10% of the inoculation amount, and placed in a constant temperature shaker at 28-30°C and 170 rpm for 4 days. After the incubation, the culture medium was centrifuged at 3000 rpm for 10 min. The supernatant was taken to measure the activity of α-galactosidase and β-mannosidase, respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com