Sandwich micro-nano fiber composite membrane loaded with microorganisms and its preparation method and application

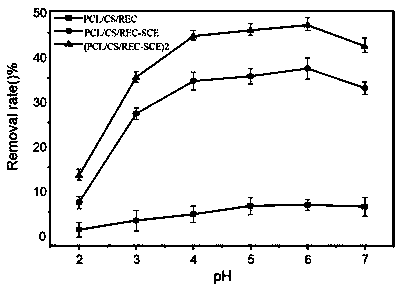

A micro-nano fiber and microorganism technology, which is applied in the field of repairing heavy metal pollution, sandwiched micro-nano fiber composite membrane and its preparation field, achieves the effects of wide adsorption concentration range, simple operation process and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

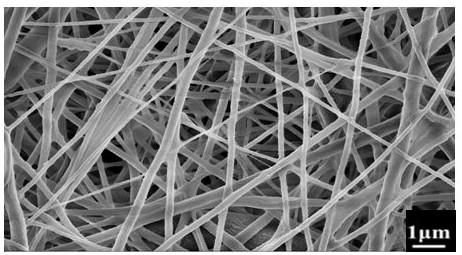

[0046] (1) First, weigh 7.56 g and 2.52 g of formic acid and acetone respectively at a mass ratio of 3:1, mix well, then add polycaprolactone and chitosan to formic acid-acetone mixed solvent, under normal temperature conditions Stir magnetically for 5 h. After polycaprolactone and chitosan were dissolved, rectorite was added, and magnetic stirring was continued at room temperature for 20 h to disperse the rectorite evenly to obtain an electrospinning solution; in the electrospinning solution, polycaprolactone The mass fraction is 9%, and the mass fraction of chitosan is 2%. The mass of rectorite is 0.5% of the total mass of polycaprolactone and chitosan.

[0047] (2) After the electrospinning solution is stirred, put it into the syringe, turn on the high voltage power supply, and adjust to the predetermined voltage. Then, the polycaprolactone micro-nanofiber membrane was prepared by electrospinning technology, and the parameters included: the perfusion rate was 1.5 mL / h, th...

Embodiment 2

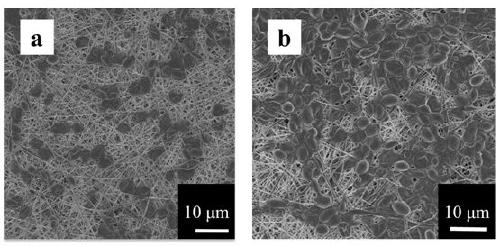

[0051] (1) First, weigh 1.04 g of polycaprolactone and 0.23 g of chitosan, respectively, and then add them into a mixed solvent of formic acid and acetone. The mass of formic acid is 7.56 g, and the mass of acetone is 2.52 g. And magnetically stirred at room temperature for 5 h. After polycaprolactone and chitosan were dissolved, rectorite was added. The quality of rectorite was 0.5% of the total mass of polycaprolactone and chitosan. Under magnetic stirring for 20 h, the rectorite was uniformly dispersed to obtain an electrospinning solution.

[0052] (2) After the electrospinning solution is stirred evenly, put it into the syringe, turn on the high voltage power supply, and adjust to the predetermined voltage. Then, the polycaprolactone micro-nanofiber membrane was prepared by electrospinning technology, and the parameters included: the perfusion rate was 1.5 mL / h, the voltage of the high-voltage DC power supply was 10 kV, the distance from the needle to the receiving plate ...

Embodiment 3

[0058] (1) First, weigh 1.04 g of polycaprolactone and 0.23 g of chitosan, respectively, and then add them into a mixed solvent of formic acid and acetone. The mass of formic acid is 7.56 g, and the mass of acetone is 2.52 g. And under normal temperature condition magnetic stirring 5h, after polycaprolactone and chitosan dissolve, add rectorite again, the quality of rectorite is 0.5% of polycaprolactone and chitosan total mass, continue Magnetic stirring was performed for 20 h to disperse the rectorite evenly to obtain an electrospinning solution.

[0059] (2) After the electrospinning solution is stirred evenly, put it into the syringe, turn on the high voltage power supply, and adjust to the predetermined voltage. Then, the polycaprolactone micro-nanofiber membrane was prepared by electrospinning technology. The parameters included: the perfusion rate was 1.5mL / h, the voltage of the high-voltage DC power supply was 10 kV, the distance from the needle to the receiving plate was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com