Method for preparing titanium dioxide hydrosol at room temperature, titanium dioxide hydrosol and application thereof

A titanium dioxide and hydrosol technology, applied in titanium oxide/hydroxide, titanium dioxide, chemical instruments and methods, etc., can solve the problem of particle aggregation and surface hydroxylation reduction, material specific surface area and hydroxylation degree reduction, powder shape Irregular appearance and other problems, to achieve the effect of saving energy, good visible light catalytic activity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, drop 0.53ml of acetic acid and 0.53ml of lactic acid into 0.42ml of acetylacetone solution, and stir it magnetically for 10 minutes at a stirring rate of 30r / min to obtain a uniform solution A; then drop 1.72ml of tetrabutyl titanate solution into Into solution A, the titration rate is 1mL / min, by magnetic stirring for 1h, the stirring rate is 50r / min, to obtain a uniform solution B; then 100ml of deionized water is added dropwise to solution B at a titration rate of 10mL / min , by magnetic stirring for 1h, the stirring rate is 50r / min, to obtain TiO 2 Hydrosol photocatalyst.

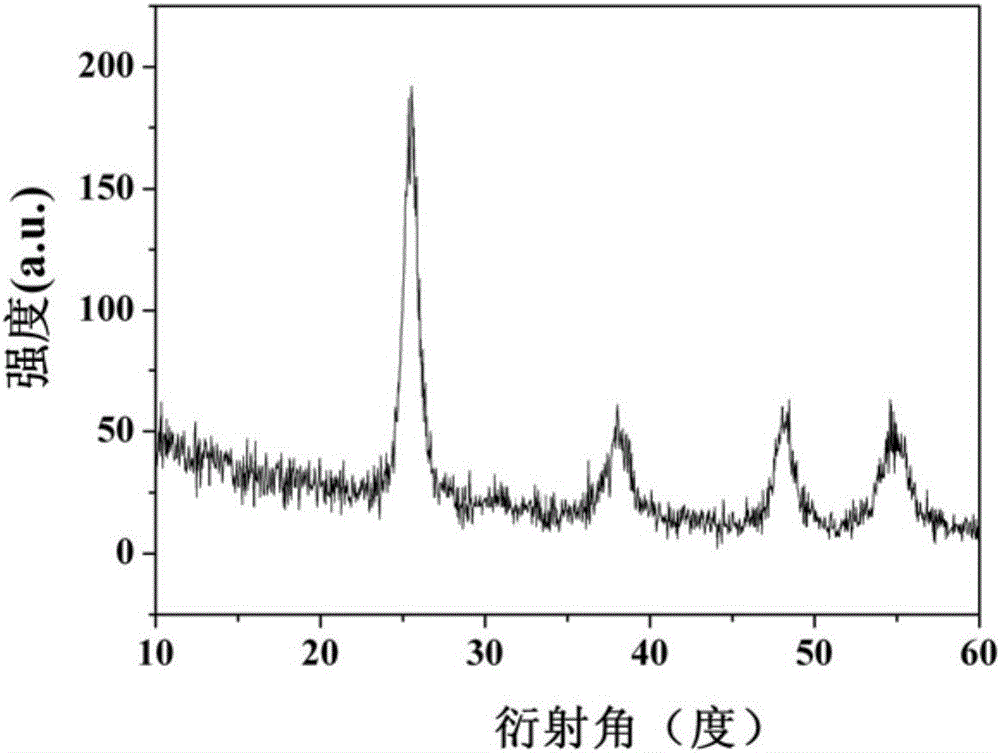

[0034] figure 1 TiO prepared for Example 1 of the present invention 2 The x-ray diffraction pattern of hydrosol after drying, by figure 1 It can be seen that the prepared TiO 2 Anatase TiO 2 .

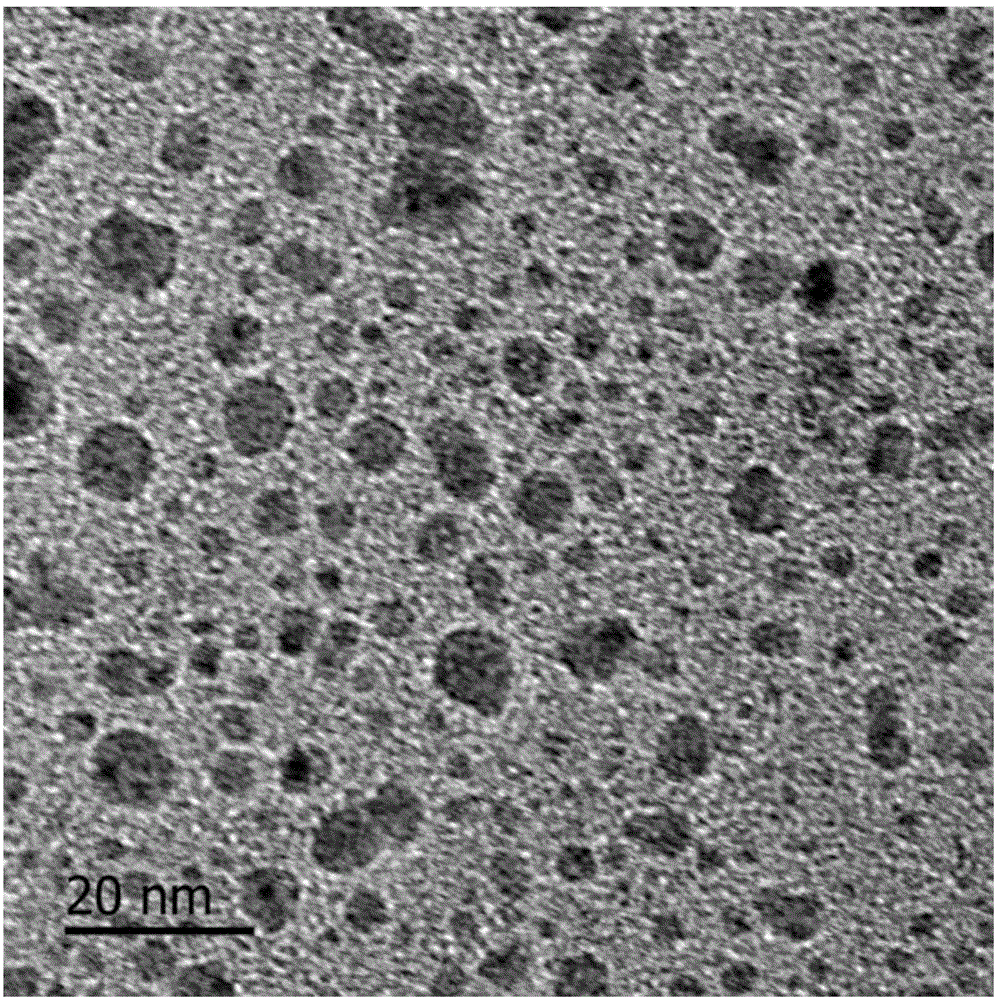

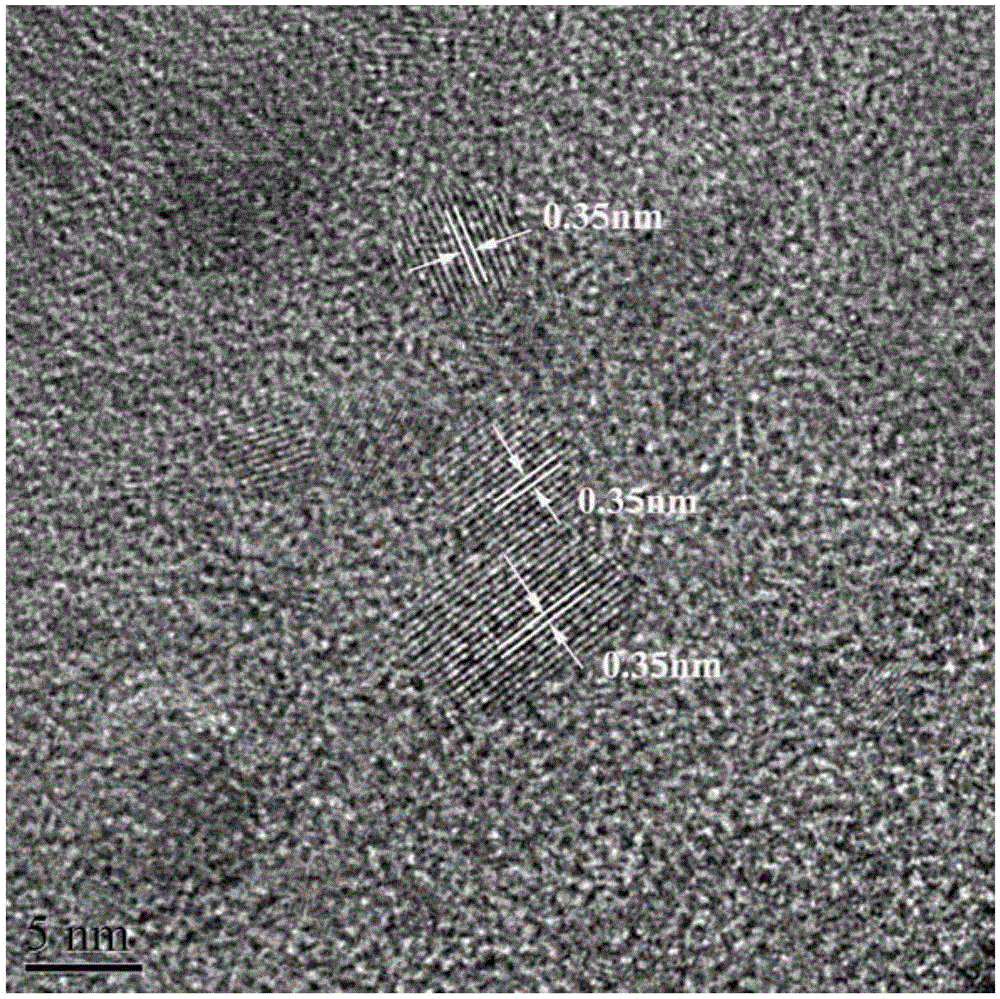

[0035] figure 2 TiO prepared for Example 1 of the present invention 2 Transmission electron microscope photographs of hydrosols, by figure 2 It can be seen that TiO 2 The particle size i...

Embodiment 2

[0039] First drop 0.42ml of acetic acid and 0.42ml of lactic acid into 0.35ml of acetylacetone solution, stir for 10min by magnetic force at a stirring rate of 40r / min to obtain a uniform solution A; then drop 1.72ml of titanium tetrachloride solution into In solution A, the titration rate is 1mL / min, and magnetically stirred for 2h at a rate of 50r / min to obtain a uniform solution B; then 100ml of deionized water is added dropwise to solution B at a titration rate of 10mL / min, By magnetic stirring for 1h, the stirring rate was 50r / min to obtain TiO 2Hydrosol photocatalyst. The visible photocatalytic performance test is the same as in Example 1, and the results show that the photocatalytic degradation rate of methyl orange is 91.8%.

Embodiment 3

[0041] First, drop 1.05ml of acetic acid and 1.05ml of lactic acid into 0.95ml of ethylenediamine solution, and stir it magnetically for 10 minutes at a stirring rate of 30r / min to obtain a uniform solution A; then drop 3.10ml of tetrabutyl titanate solution into solution A, the titration rate is 1mL / min, stirred by magnetic force for 2h, and the stirring rate is 60r / min, to obtain a uniform solution B; In, by magnetic stirring for 2h, the stirring rate is 60r / min, to obtain TiO 2 Hydrosol photocatalyst. The visible light photocatalytic performance test is the same as in Example 1, and the results show that the photocatalytic degradation rate of methyl orange is 93.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com