Silver-carrying nanometer titanium dioxide and preparation method thereof

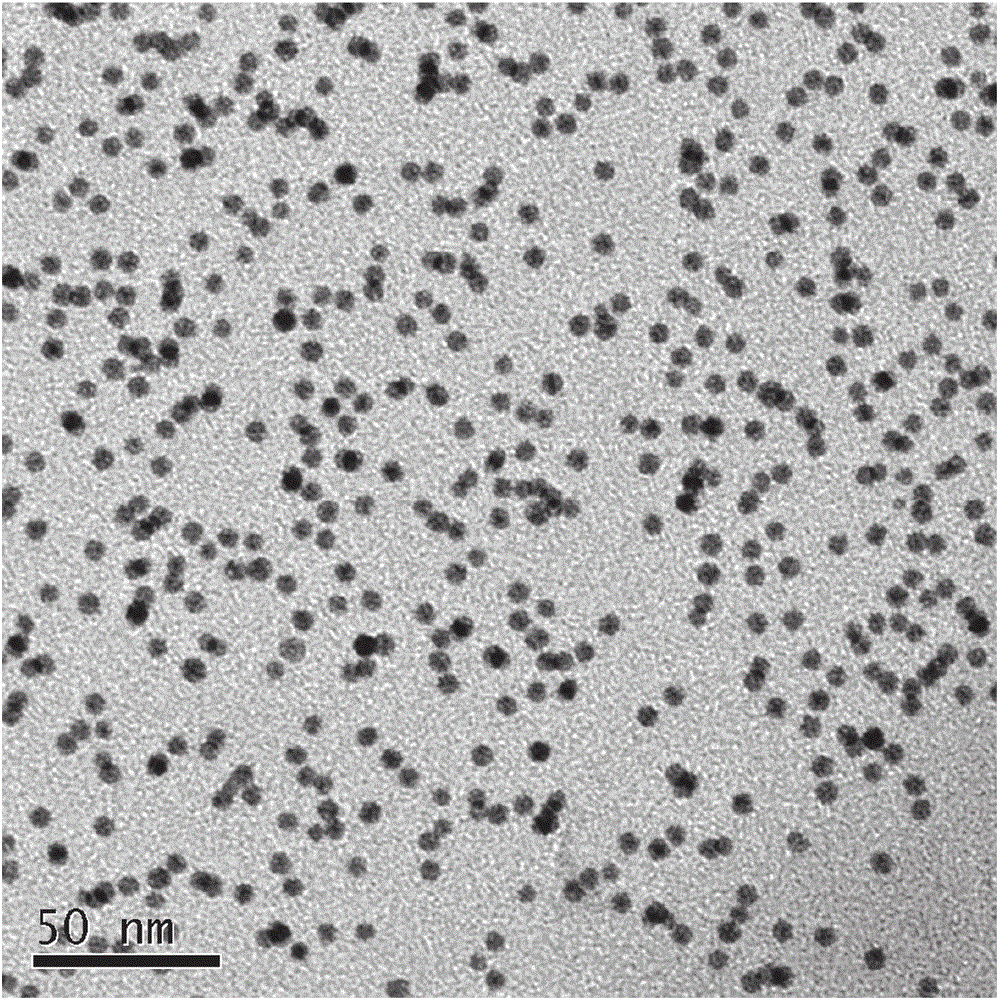

A nano-titanium dioxide and silver-carrying technology, applied in nanotechnology and other directions, can solve the problems of high local concentration, poor dispersion, uneven particle size and shape of materials, and achieve the effects of rapid material mixing, narrow size distribution, and uniform particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

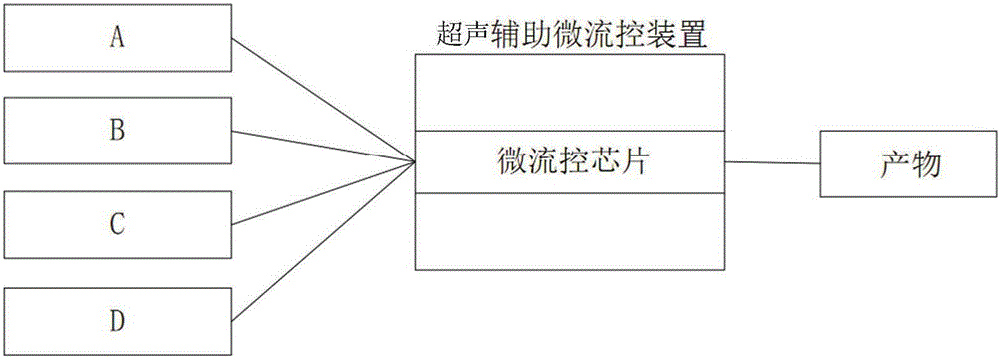

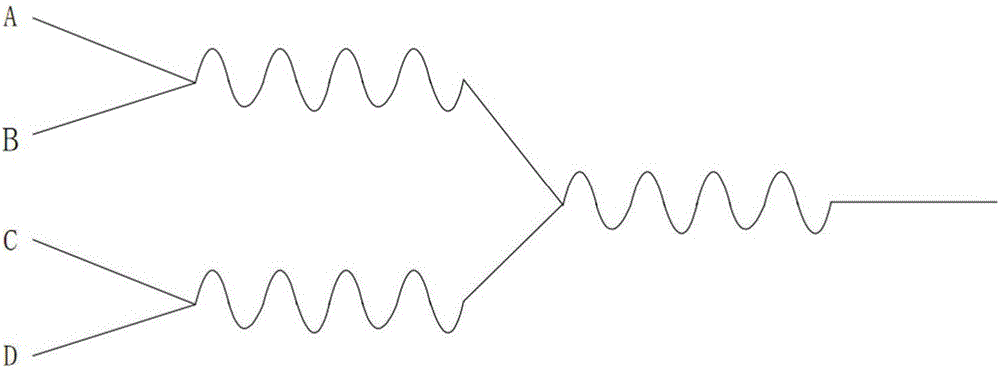

[0028] The invention discloses a preparation method of silver-loaded nano-titanium dioxide, which adopts an ultrasonic-assisted microfluidic method, through ultrasonic-assisted mixing and dispersion, and raw materials are mixed in a microchannel to form silver-loaded nano-titanium dioxide.

[0029] Specifically, the method uses silver nitrate solution (concentration is 0.6mmol / L) as material A, and adds surfactant (such as sodium citrate) and sodium hydroxide in sodium borohydride solution (concentration is 4mmol / L) as Material B, with titanium tetrachloride as material C, add surfactant (as polyethylene glycol) in ammoniacal liquor (concentration is 8wt%) as material D, the consumption of surfactant sodium citrate and polyethylene glycol is It is well known to those skilled in the art and will not be repeated here.

[0030] Such as figure 1 As shown, the material A, material B, material C, and material D are respectively pumped into the microfluidic chip through four pumps, ...

Embodiment 2

[0034] Carry out according to the method similar to embodiment 1, difference is, silver nitrate solution concentration is 1mmol / L, and sodium borohydride solution concentration is 9mmol / L, and ammoniacal liquor concentration is 10wt%, sodium borohydride, silver nitrate, sodium hydroxide The molar ratio is 1:3:6, the molar ratio of titanium tetrachloride and ammonia water is 1:5, the mass ratio of nano-silver and nano-titanium dioxide is 1:6, the reaction temperature is 98°C, and the reaction time is 10s.

Embodiment 3

[0036] Carry out according to the method similar to Example 1, difference is, silver nitrate solution concentration is 0.3mmol / L, and sodium borohydride solution concentration is 2mmol / L, and ammoniacal liquor concentration is 7wt%, sodium borohydride, silver nitrate, hydroxide The molar ratio of sodium is 1:6:3, the molar ratio of titanium tetrachloride and ammonia water is 1:3, the mass ratio of nano-silver and nano-titanium dioxide is 1:5, the reaction temperature is 40°C, and the reaction time is 60s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com