Antibacterial ceramic with sand texture and production technology of ceramic

A production process and texture technology, applied in the field of ceramic products, can solve the problems of poor bacteria control effect, silver ion volatilization, discoloration glaze, etc., achieve long service life, increase friction, and prevent slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

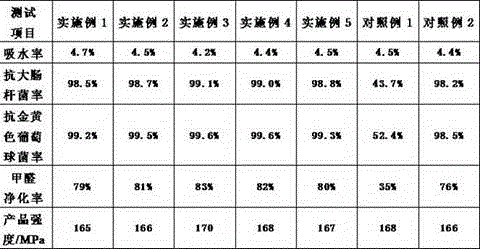

Examples

Embodiment 1

[0025] An antibacterial ceramic with sandstone texture, comprising the following raw materials in parts by mass: 16 parts of Longyan kaolin, 7 parts of spodumene, 14 parts of ordinary quartz sand, 15 parts of albite, 6 parts of waste porcelain slag, 1 part of talcum powder, 3 parts of calcium oxide, 2 parts of titanium dioxide, and 2 parts of chitin.

[0026] The above-mentioned manufacturing process of a kind of antibacterial and sandy textured ceramics comprises the following steps:

[0027] (1) Separately select spodumene, albite and waste porcelain slag to remove impurities, and crush them until the particle size is less than 4mm;

[0028] (2) Deacetylation of chitin;

[0029] (3) Mix all components except ordinary quartz sand according to the formula and add water, then put it into a ball mill for 24 hours, and screen the mud fineness to pass through a 300-mesh sieve;

[0030] (4) Carry out magnetic separation to remove iron impurities contained in the mud raw materials...

Embodiment 2

[0035] An antibacterial ceramic with sandstone texture, comprising the following raw materials in parts by mass: 19 parts of Longyan kaolin, 8 parts of spodumene, 16 parts of ordinary quartz sand, 17 parts of albite, 7 parts of waste porcelain slag, 2 parts of talcum powder, 4 parts of calcium oxide, 2 parts of titanium dioxide, and 3 parts of chitin.

[0036] The above-mentioned manufacturing process of a kind of antibacterial and sandy textured ceramics comprises the following steps:

[0037] (1) Separately select spodumene, albite and waste porcelain slag to remove impurities, and crush them until the particle size is less than 4mm;

[0038] (2) Deacetylation of chitin;

[0039] (3) Mix all components except ordinary quartz sand according to the formula and add water, then put it into a ball mill for 24 hours, and screen the mud fineness to pass through a 300-mesh sieve;

[0040] (4) Carry out magnetic separation to remove iron impurities contained in the mud raw material...

Embodiment 3

[0045] An antibacterial ceramic with sandstone texture, comprising the following raw materials in parts by mass: 21 parts of Longyan kaolin, 10 parts of spodumene, 18 parts of ordinary quartz sand, 19 parts of albite, 8 parts of waste porcelain slag, 3 parts of talc, 5 parts of calcium oxide, 3 parts of titanium dioxide, 4 parts of chitin.

[0046] The above-mentioned manufacturing process of a kind of antibacterial and sandy textured ceramics comprises the following steps:

[0047] (1) Separately select spodumene, albite and waste porcelain slag to remove impurities, and crush them until the particle size is less than 4mm;

[0048] (2) Deacetylation of chitin;

[0049] (3) Mix all components except ordinary quartz sand according to the formula and add water, then put it into a ball mill for 24 hours, and screen the mud fineness to pass through a 350-mesh sieve;

[0050] (4) Carry out magnetic separation to remove iron impurities contained in the mud raw materials;

[0051]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com