High-ultraviolet-shielding high-barrier nanomaterial film and preparation method thereof

A material film, high-barrier technology, applied in the field of high-ultraviolet shielding and high-barrier nanomaterial film and its preparation, can solve the problems of easy penetration and restrict the application of PE film materials, and achieve scientific and reasonable preparation methods and excellent ultraviolet Shielding performance, significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

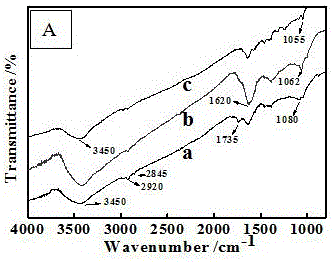

[0023] (1) Preparation of GONRs: First, 180 mL of concentrated H 2 SO 4 Slowly added to the round bottom flask and stirred, then 20 mLH 3 PO 4 Slowly drop in, mix evenly at a certain speed, slowly add 1 g MWCNTs and stir for 30 min until uniform, then add 6 g KMnO 4 Slowly added to the above mixture; the above reaction system was stirred in an oil bath at 50 °C for 24 h, then cooled to room temperature, and then poured into a solution containing 10 mL H 2 o 2 500 mL of deionized water was stirred in an ice bath for 1 h. At this time, the solution turned dark green, indicating that the reaction was complete. Then, an appropriate amount of HCl was added and centrifuged until neutral, and finally dried in a freeze dryer to obtain GONRs;

[0024] (2) Preparation of EGONRs: Dissolve 100 mg GONRs in 100 mL deionized water, and 100 W ultrasonic for 1 h to form a uniform dispersion; add a certain amount of HCl to adjust the pH to 1~2; then add 0.5 g ethanolamine to react at room t...

Embodiment 1

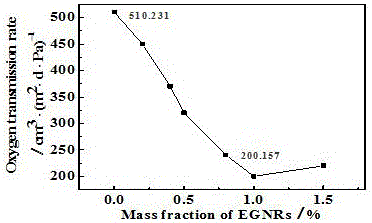

[0030] Take 5 g of LDPE in a round bottom flask, add 30 mL of xylene, heat up to 80 °C and stir until it becomes a paste; dissolve 0.05 g of EGNRs in 10 mL of xylene, slowly pour it into the round bottom flask, and stir evenly; Slowly pour the mixed solution into a large amount of absolute ethanol to stir and flocculate, filter and dry to obtain the EGNRs / LDPE masterbatch, and then add the obtained EGNRs / LDPE masterbatch and LDPE pellets into the twin-screw extruder at a ratio of 1:1. Melt extrusion and granulation at 140°C, and finally a 0.5wt% EGNRs / LDPE composite film was prepared by tablet cutting with a flat vulcanizer.

Embodiment 2

[0032]Take 12.5 g LDPE in a round-bottomed flask, add 60 mL of xylene, heat up to 80 °C and stir until it becomes a paste; dissolve 0.05 g of EGNRs in 10 mL of xylene, slowly pour it into the round-bottomed flask, and stir evenly; Slowly pour the mixed solution into a large amount of absolute ethanol to stir and flocculate, filter and dry to obtain EGNRs / LDPE masterbatch, then add the obtained EGNRs / LDPE masterbatch and LDPE pellets into the twin-screw extruder at a ratio of 1:1 Melt extrusion and granulation at 140°C, and finally a 0.2wt% EGNRs / LDPE composite film was prepared by pressing and cutting with a flat vulcanizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com