Yeast culture and preparing method and application thereof

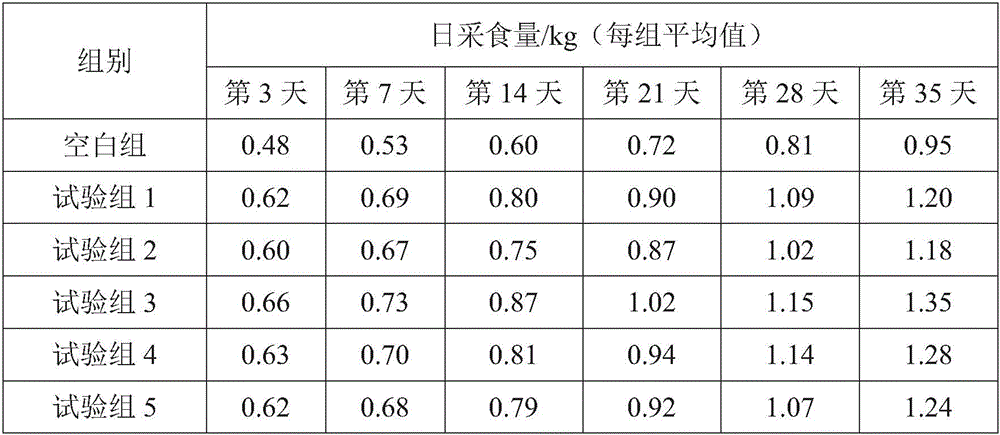

A technology of yeast culture and yeast, which is applied in the field of yeast culture and its preparation, can solve the problems of being unable to be popularized in a large scale, long production time, and large floor area, so as to achieve improved daily feed intake, good quality, The effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, the preparation of yeast culture

[0029] 1. Activation of slant strains: inoculate the Saccharomyces cerevisiae with the preservation number of CGMCC No.2.399 frozen and preserved on the slant medium containing malt extract powder 130g / L, chloramphenicol 0.1g / L, and agar 2%. Keep the temperature at 28°C and culture for 40 hours to obtain activated yeast strains.

[0030] 2. Preparation of seed liquid: Inoculate the activated yeast strain with 1 loop into liquid medium containing malt extract powder 130g / L, chloramphenicol 0.1g / L; pH value is 5.6, shake at 28°C Bed culture, rotation speed 120r / min; culture 18h.

[0031] 3. Liquid aerobic fermentation: Inoculate the prepared seed liquid with 10% inoculum into a new liquid culture medium containing malt extract powder 130g / L, chloramphenicol 0.1g / L; pH value 5.6 The expanded culture was carried out in the tank, the ventilation rate was controlled to be 5 L / min, the temperature was 28° C., and the fermentat...

Embodiment 2

[0038] Embodiment 2, the preparation of yeast culture

[0039] The difference from Example 1 is that the composition of the solid medium is 7 parts of straw, 5 parts of corn flour and 1 part of bran.

[0040] The carbon to nitrogen ratio of the solid medium was 4:1.

[0041] The cell wall-breaking enzyme is pectinase, purchased from Sigma Company in the United States; the enzyme activity of pectinase is 5.0 U / mg.

[0042] The enzyme activity of pectinase is defined as follows:

[0043] Under the condition of 50°C and pH value of 4.0, the amount of enzyme needed to decompose polygalacturonic acid to produce 1 μmol galacturonic acid in 1 minute is 1 enzyme activity unit.

[0044] After testing, the crude protein content of the product prepared in this example is 14.5%, the mannan content is 1.0%, the B-glucan content is 3.8%, and the ash content is 6.5%.

Embodiment 3

[0045] Embodiment 3, the preparation of yeast culture

[0046] This embodiment is the best implementation mode of this application.

[0047] 1. Activation of slant strains: inoculate the Saccharomyces cerevisiae with the preservation number of CGMCC No.2.399 frozen and preserved on the slant medium containing malt extract powder 130g / L, chloramphenicol 0.1g / L, and agar 2%. Keep the temperature at 30°C and culture for 48 hours to obtain activated yeast strains.

[0048] 2. Preparation of seed liquid: Inoculate the activated yeast strain with 1 loop into liquid medium containing malt extract powder 130g / L, chloramphenicol 0.1g / L; pH value is 6.5, and shake at a constant temperature of 30°C Bed culture, rotation speed 160r / min; culture 24h.

[0049] 3. Liquid aerobic fermentation: Inoculate the prepared seed liquid with 20% inoculation amount into a new liquid culture medium containing malt extract powder 130g / L, chloramphenicol 0.1g / L; pH value 5.6 Expanded culture was carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com