Graphene composite electrode material with excellent electricity storage performance and preparation method thereof

A graphene composite and electrode material technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems such as impenetrability, achieve reliable performance, excellent electrical conductivity, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

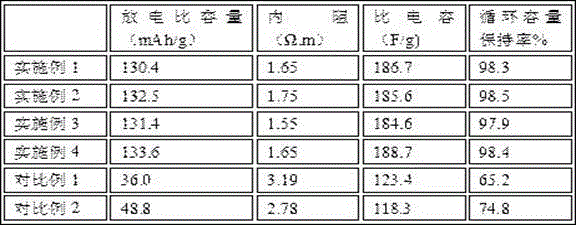

Examples

Embodiment 1

[0022] (1) Weigh 30 parts of graphene, 3 parts of polyvinylidene fluoride, 5 parts of tetraethylene glycol, 2 parts of polyoxyethylene lauryl ether, 2 parts of tricarboxymethylpropane glycidyl ether, and 3 parts of coconut oil in parts by weight , 1 part of phthalic anhydride, 4 parts of triethanolamine salt, 3 parts of aluminum hydroxide, 4 parts of magnesium carbonate, 2 parts of oxalic acid, 1 part of ammonium dihydrogen phosphate, 4 parts of N-methyl-2-pyrrolidone, vinyl tri 3 parts of ethoxysilane, 3 parts of dimethyltriphenylmethane tetraisocyanate;

[0023] (2) Add graphene to concentrated sulfuric acid to oxidize to obtain graphene oxide materials, which are ultrasonically dispersed in N-methyl-2-pyrrolidone, and polyvinylidene fluoride, tetraethylene glycol, and polyoxyethylene lauryl are added at the same time Ether, tricarboxymethylpropane glycidyl ether, coconut oil, phthalic anhydride to obtain a graphene suspension, the ultrasonic power is 300W, and the ultrasoni...

Embodiment 2

[0030] (1) Weigh 35 parts of graphene, 4 parts of polyvinylidene fluoride, 7 parts of tetraethylene glycol, 3 parts of polyoxyethylene lauryl ether, 3 parts of tricarboxymethylpropane glycidyl ether, and 4 parts of coconut oil in parts by weight , 2 parts of phthalic anhydride, 5 parts of triethanolamine salt, 5 parts of aluminum hydroxide, 6 parts of magnesium carbonate, 3 parts of oxalic acid, 1 part of ammonium dihydrogen phosphate, 5 parts of cetyltrimethylammonium bromide, 3 parts - 4 parts of aminopropyltrimethoxysilane, 6 parts of sodium carboxymethylcellulose;

[0031] (2) Add graphene to concentrated sulfuric acid to oxidize to obtain graphene oxide materials, which are ultrasonically dispersed in cetyltrimethylammonium bromide, and polyvinylidene fluoride, tetraethylene glycol, polyoxygen Ethylene lauryl ether, tricarboxymethylpropane glycidyl ether, coconut oil, phthalic anhydride to obtain a graphene suspension, the ultrasonic power is 350W, and the ultrasonic time...

Embodiment 3

[0038] (1) Weigh 40 parts of graphene, 5 parts of polyvinylidene fluoride, 9 parts of tetraethylene glycol, 4 parts of polyoxyethylene lauryl ether, 4 parts of tricarboxymethylpropane glycidyl ether, and 5 parts of coconut oil in parts by weight , 3 parts of phthalic anhydride, 6 parts of triethanolamine salt, 8 parts of aluminum hydroxide, 8 parts of magnesium carbonate, 4 parts of oxalic acid, 2 parts of ammonium dihydrogen phosphate, 6 parts of sodium dodecylbenzenesulfonate, 3-shrink 5 parts of glyceryl etheroxypropyl trimethoxysilane, 7 parts of nitrile-phenolic resin;

[0039] (2) Add graphene to concentrated sulfuric acid to oxidize to obtain graphene oxide materials, which are dispersed in sodium dodecylbenzenesulfonate by ultrasonic waves, and polyvinylidene fluoride, tetraethylene glycol, and polyoxyethylene lauryl are added at the same time Ether, tricarboxymethylpropane glycidyl ether, coconut oil, phthalic anhydride to obtain a graphene suspension, the ultrasonic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com