Preparation method of adhesive for recombined material

A technology of adhesives and recombined materials, applied in the direction of adhesives, adhesive types, starch adhesives, etc., can solve the problems of insufficient environmental protection, poor toughness, and low formaldehyde emission, and achieve less volatile organic compounds and high environmental protection Sexuality, good toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

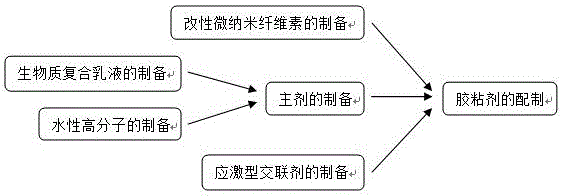

Method used

Image

Examples

Embodiment 1

[0032]a. Preparation of modified micro-nano cellulose: the wood or straw fiber from which lignin and hemicellulose has been removed is stirred and reacted at 60°C for 2 hours with an acid solution with a mass fraction of 45% to form a cellulose slurry, and then the Add water to the cellulose slurry to adjust the concentration to 1.8%, then pretreat the cellulose slurry at 8°C, ultrasonic power 650W, and ultrasonic frequency 20kHz for 40min at low temperature, and then press the cellulose slurry under a pressure of 100MPa Homogeneous circulation 6 times, then add water to the cellulose slurry to adjust the concentration to 1.5%, then add 2% of the mass of the cellulose slurry silane coupling agent and at 40 ° C, nitrogen at an air flow rate of 18ml / min After deoxygenation for 7 minutes, an in-situ ultrasonic reaction was performed at an ultrasonic power of 750W and an ultrasonic frequency of 20kHz for 18 minutes to obtain the modified micro-nanocellulose; the silane coupling ag...

Embodiment 2

[0039] a. Preparation of modified micro-nano cellulose: the wood or straw fiber from which lignin and hemicellulose has been removed is stirred and reacted at 40°C for 3 hours with an acid solution with a mass fraction of 30% to form a cellulose slurry, and then the Add water to the cellulose slurry to adjust the concentration to 1.5%, then pretreat the cellulose slurry with low-temperature ultrasonic pretreatment at 10°C, ultrasonic power 1000W, and ultrasonic frequency 22kHz for 60min, and then press the cellulose slurry under a pressure of 120MPa Homogeneous circulation 7 times, then add water to the cellulose slurry to adjust the concentration to 1%, then add 2% silane coupling agent of the mass of the cellulose slurry and heat at 40°C, nitrogen at an airflow rate of 30ml / min After deoxygenation for 3 minutes, an in-situ ultrasonic reaction was carried out at an ultrasonic power of 900W and an ultrasonic frequency of 18kHz for 20 minutes to obtain the modified micro-nanoce...

Embodiment 3

[0046] a. Preparation of modified micro-nano cellulose: the wood or straw fiber from which lignin and hemicellulose has been removed is stirred and reacted at 80°C for 1 hour with an acid solution with a mass fraction of 60% to form a cellulose slurry, and then the Add water to the cellulose slurry to adjust the concentration to 1.8%, then pretreat the cellulose slurry with low-temperature ultrasonic at 5°C, ultrasonic power 1000W, and ultrasonic frequency 22kHz for 30min, and then press the cellulose slurry under a pressure of 150MPa Homogeneous circulation 2 times, then add water to the cellulose slurry to adjust the concentration to 2%, then add 3% of the mass of the cellulose slurry silane coupling agent and at 30 ° C, nitrogen at an air flow rate of 5ml / min After deoxygenation for 10 minutes, an in-situ ultrasonic reaction was carried out at an ultrasonic power of 600W and an ultrasonic frequency of 22kHz for 30 minutes to obtain the modified micro-nanocellulose; the sila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com