Method for producing macro-element water-soluble fertilizer by utilizing potassium-containing rocks

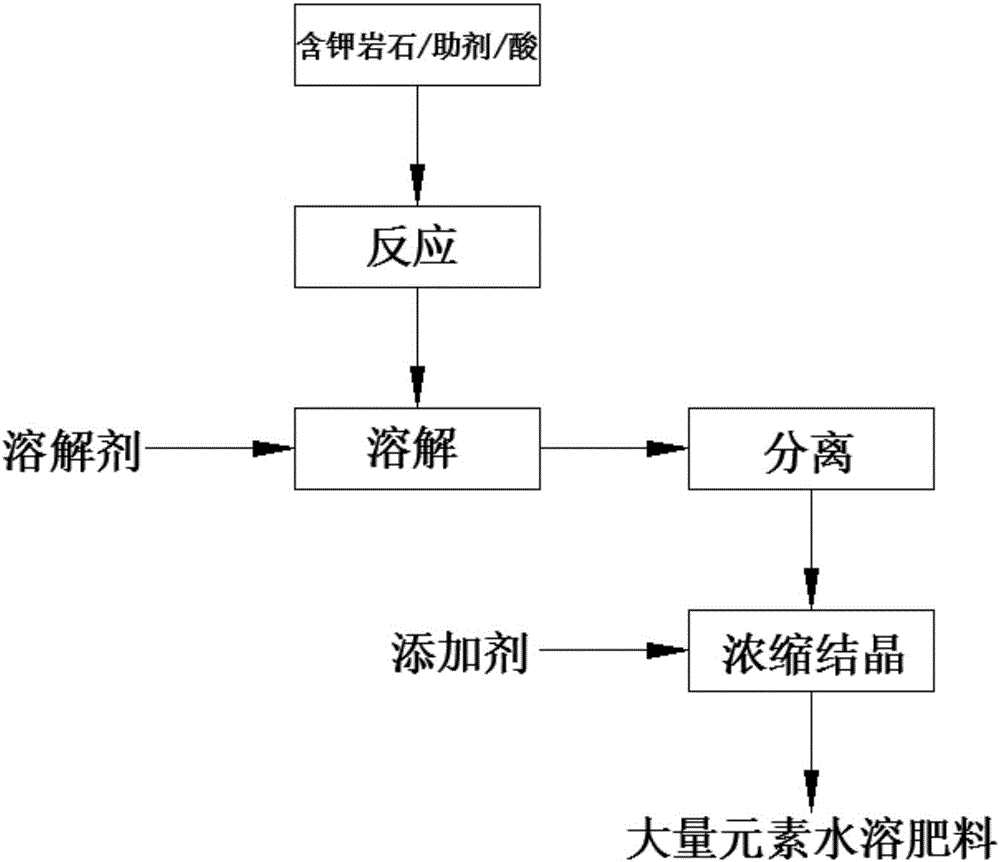

A technology based on a large amount of elements and potassium rocks, applied in the field of water-soluble fertilizers, can solve the problems of uneven nutrients in water-soluble fertilizers, low crop absorption rate, soil compaction, etc., achieve excellent appearance, increase crop absorption rate, and reduce environmental pollution rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Crush the potassium-containing rock to 100 mesh, mix it with fluosilicic acid with a concentration of 25% by mass, and sulfuric acid with a concentration of 98% by mass according to the following mixing ratio. For 1 ton of potassium-containing rock powder, add 5 cubic meters of fluorine Silicic acid and 0.5 cubic meters of sulfuric acid were heated to 100°C in a reaction kettle for 4 hours, and the reaction solution was filtered off to obtain a solid;

[0039] The volume of solid and ammonia water is 1t: 1.2m according to the mass ratio 3 Mix the proportions, react in the dissolution tank for 1.5h, and then separate the solid and liquid to obtain the residue and filtrate, and then add 4 tons of potassium nitrate, potassium dihydrogen phosphate, EDTA chelated copper, EDTA chelated The mixture of zinc according to any mass ratio is uniformly stirred, then concentrated, crystallized and dried to obtain a water-soluble fertilizer with a large amount of elements.

Embodiment 2

[0041] The potassium-containing rock is crushed to 150 mesh, and mixed with hydrofluoric acid with a mass percentage concentration of 35% and nitric acid with a mass percentage concentration of 90% according to the following mixing ratio. For 1 ton of potassium-containing rock powder, add 2 cubic meters of hydrogen Fluoric acid and 1 cubic meter of nitric acid were heated to 80°C in a reaction kettle for 2 hours, and the reaction solution was evaporated to dryness to obtain a solid;

[0042] The solid and urea solution are 1t: 1m according to the mass ratio volume 3 Mix in proportion, react in the dissolving tank for 0.5h, and then separate the solid and liquid to obtain the residue and filtrate, then add 3 tons of potassium pyrophosphate, ammonium sulfate, boric acid, and ammonium molybdate to 1 cubic meter of filtrate according to any mass ratio After the mixture is evenly stirred, it is concentrated, crystallized and dried to obtain a water-soluble fertilizer with a large a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com