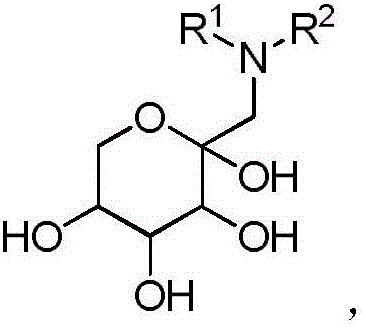

Aminoketose organic steel bar corrosion inhibitor and preparation method thereof

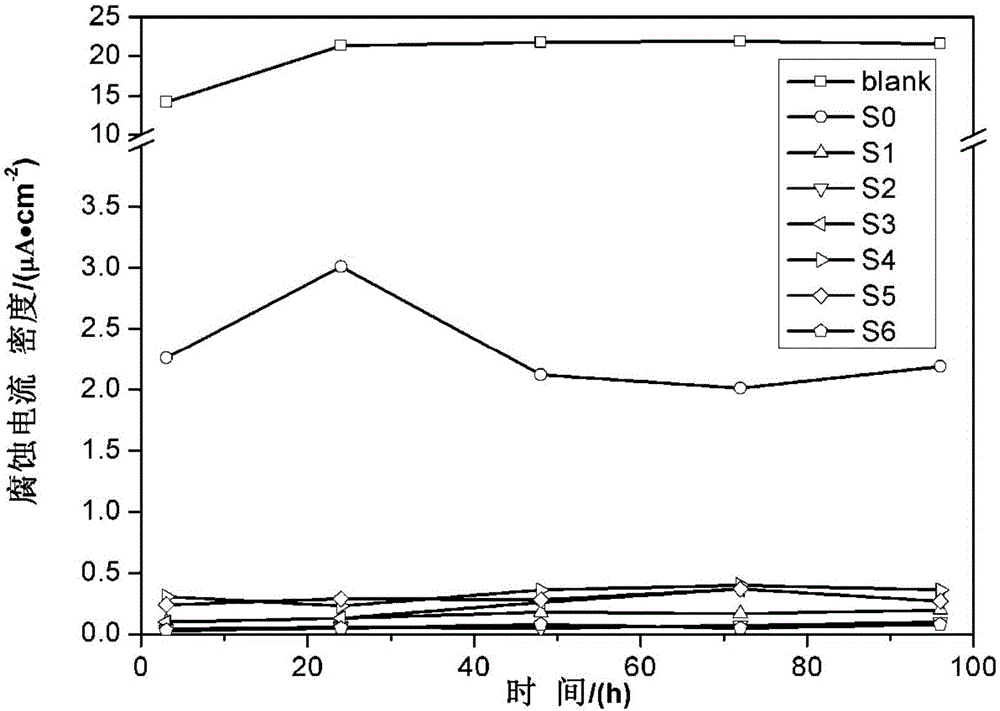

A kind of steel bar rust inhibitor and amino ketone technology, applied in the field of building materials, can solve the problems of cumbersome post-processing, high application cost, accelerated dissolution of passivation film, etc., to avoid environmental pollution and ecological damage, excellent rust inhibition performance, synthetic simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Glucose (0.2mol, 36g) was added to a round-bottomed flask, followed by 7mL of water, n-butylamine (0.22mol, 16g) and acetic acid (0.002mol, 0.12g), reacted at 80°C for 4 hours under mechanical stirring, and cooled to room temperature, add 340mL of water to dilute to obtain the aminoketose organic steel rust inhibitor.

Embodiment 2

[0031] Glucose (0.2mol, 36g) was added to a round-bottomed flask, followed by 7mL of water, p-methylaniline (0.21mol, 23g) and acetic acid (0.004mol, 0.24g), and reacted at 95°C for 2 hours under mechanical stirring. Cool to room temperature, add 380mL of water to dilute to obtain the aminoketose organic steel rust inhibitor.

Embodiment 3

[0033] Galactose (0.2mol, 36g) was added to a round bottom flask, followed by 7mL of water, N,N-dimethyl-1,3-propanediamine (0.24mol, 25g) and acetic acid (0.004mol, 0.24g ), reacted at 90° C. for 3 hours under mechanical stirring, cooled to room temperature, and diluted with 390 mL of water to obtain the aminoketose organic steel rust inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com