Linear block copolymer, dendritic nano-silver composite and preparation methods of linear block copolymer and dendritic nano-silver composite

A technology of block copolymers and composite materials, which is applied in the field of dendritic nano-silver composite materials to achieve the effects of strong anti-interference, good electrocatalytic activity, and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Synthesis of Chain Transfer Agents

[0058]

[0059] Synthesize the chain transfer agent according to the above reaction formula, these reactions are known conventional reactions, and can be carried out according to the usual reaction conditions, and will not be repeated.

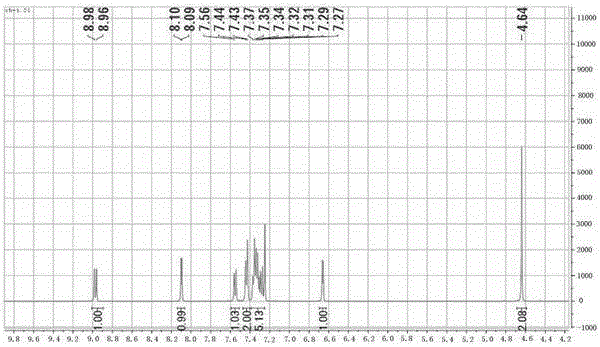

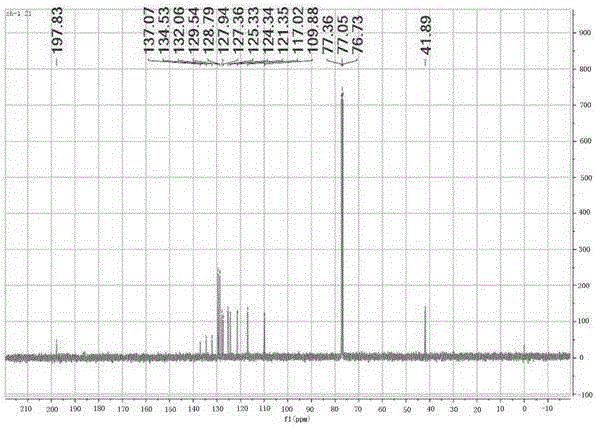

[0060] chain transfer agent 1 H NMR spectrum such as figure 1 as shown, 13 C NMR spectrum as figure 2 As shown, the MS spectrum is as image 3 As shown, the FT-IR spectrum is as Figure 4 As shown, these characterization data can prove that the chain transfer agent was synthesized.

Embodiment 2

[0062] Synthesis of Linear Block Copolymers

[0063] 1. Add 0.04g of chain transfer agent compound 1 into a 100mL three-neck flask, vacuumize for 15min in an ice-water bath, then pass nitrogen for 15min, repeat 3 times, and rise to room temperature. g methyl methacrylate and 1 g monomer hydroxyethyl methacrylate were reacted at a constant temperature of 65° C. for 3 h, and the reaction was terminated by liquid nitrogen. Use chloroform as a precipitating agent to separate, then dissolve in ethanol, repeat the dissolution-precipitation operation 3 times to achieve purification, and obtain polymer 2.

[0064] 2. Add 0.15g of polymer 2 into the reaction flask, add 0.8g of initiator AIBN and 1g of N-vinylpyrrolidone under the protection of nitrogen, react at a constant temperature of 70°C for 4h, and terminate the reaction with liquid nitrogen. Acetone was used as a precipitating agent for separation, and then dissolved in ethanol, and the dissolution-precipitation operation was r...

Embodiment 3

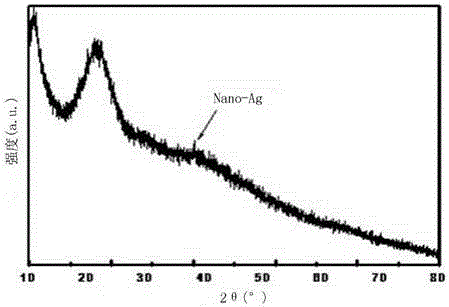

[0070] Self-assembly of dendritic nanosilver composites

[0071] 1. The linear block copolymer obtained in Example 2 is made into a 2wt% aqueous solution, and the block copolymer can self-assemble into nanomicelles in an aqueous solution, wherein the relative lipophilic segments containing a certain amount of hydroxyl groups constitute the micelles. The inner core, the hydrophilic chain segment constitutes the outer shell of the micelles, this structure provides a "nano device" for the follow-up;

[0072] 2. Add silver nitrate to the aqueous solution, mix well, add reducing agent at room temperature, stir for 6 minutes, the solution gradually changes from colorless to light brown; the amount of silver nitrate is 2% of the mass of the linear block copolymer, silver nitrate and The molar ratio of the reducing agent is 1:1.4, and the reducing agent is hydrazine;

[0073] 3. Put it into a dialysis bag after standing still for 24 hours, dialyze with ethanol and deionized water for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com