Polycarboxyliy water reducer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, applied in the field of polycarboxylate water reducing agent and its preparation, can solve the problem that shrinkage reduction performance and water reduction performance cannot be taken into account at the same time, achieve easy control of reaction conditions, enhance impact resistance, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

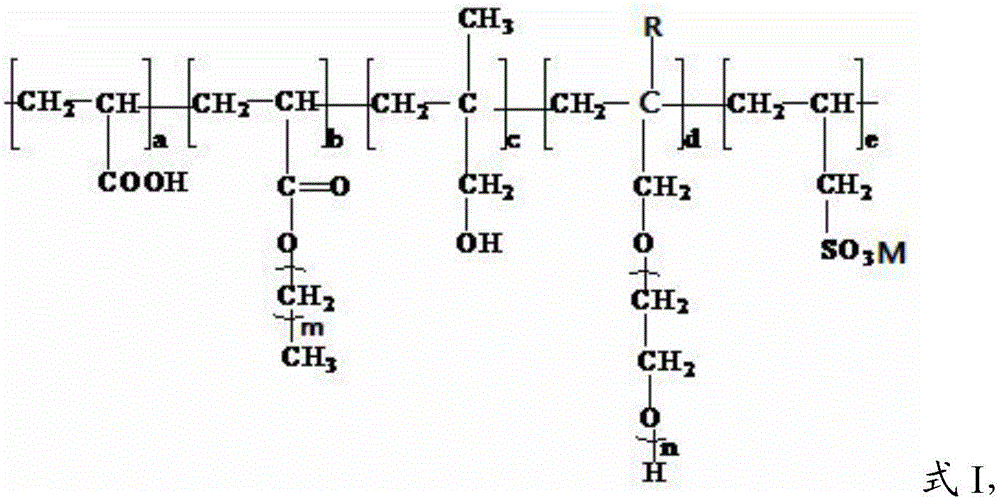

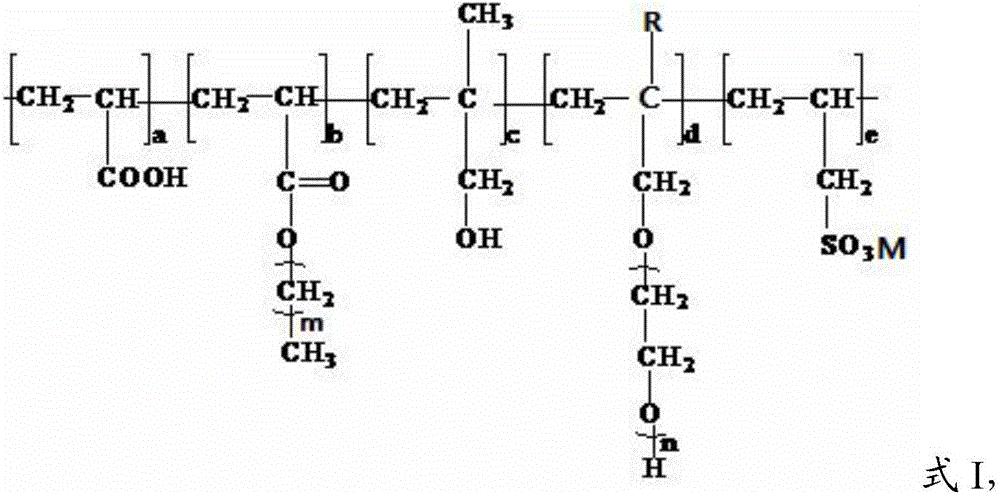

[0034] The present invention provides a method for preparing a water reducer with a structure represented by formula I described in the above technical solution, comprising the following steps:

[0035] In the presence of an initiator and a molecular weight regulator, polyoxyethylene ether, acrylate, allyl alcohol, acrylic acid and allyl sulfonate are subjected to a copolymerization reaction in water to obtain a water reducer with the structure shown in formula I.

[0036] In the present invention, the mass ratio of polyoxyethylene ether, acrylate, allyl alcohol, acrylic acid, and allyl sulfonate is preferably (270-380): (2-15): (3-9): (20~60): (1~9), more preferably (300~360): (4~12): (4~8): (30~50): (3~8), most preferably (320 ~350): (6~9): (5~7): (35~45): (4~6).

[0037] In the present invention, the mass ratio of the polyoxyethylene ether, initiator, molecular weight regulator and water is preferably (270-380): (1-8): (1-7): (580-660), more preferably Preferably (300~360...

Embodiment 1

[0052] The raw material is calculated in parts by mass, and its preparation method comprises the steps:

[0053] Under normal temperature conditions, add 270 parts of isobutylene alcohol polyoxyethylene ether polyoxyethylene ether with a number average molecular weight of 2699, 2 parts of propyl acrylate, 3 parts of allyl alcohol, and 580 parts of water into the reactor, stir and dissolve, and respectively Add dropwise 20 parts of acrylic acid, 1 part of sodium allyl sulfonate, 1 part of hydrogen peroxide and ascorbic acid, and 1 part of 3-mercaptopropionic acid molecular weight regulator, and carry out free radical copolymerization at 20 ° C for 3 hours. Insulate at 20° C. for 1 hour to obtain a polycarboxylate water reducer with the structure shown in formula I.

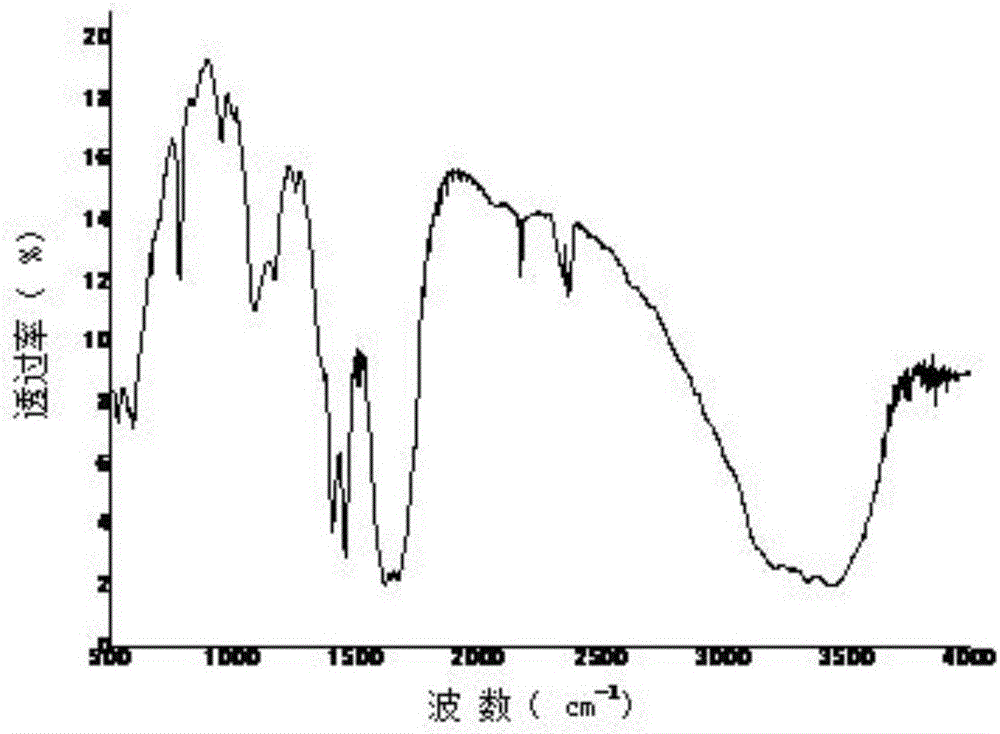

[0054] figure 1 The infrared spectrogram of the polycarboxylate water-reducer with structure shown in formula I that embodiment 1 makes, as can be seen from the figure, at 3424cm -1 There is an absorption peak on...

Embodiment 2

[0057] The raw material is calculated in parts by mass, and its preparation method comprises the steps:

[0058] Under normal temperature conditions, add 380 parts of isopentenol polyoxyethylene ether polyoxyethylene ether with a number average molecular weight of 3100, 15 parts of ethyl acrylate, 9 parts of allyl alcohol, and 660 parts of water into the reactor, and stir to dissolve , add dropwise 60 parts of acrylic acid, 9 parts of allyl potassium sulfonate, 8 parts of hydrogen peroxide and ascorbic acid, and 7 parts of azobisisobutyronitrile molecular weight regulator, and carry out free radical copolymerization at 35 ° C for 10 h , after completion, keep it warm at 35° C. for 5 hours to obtain a polycarboxylate water reducer with the structure shown in formula I.

[0059] According to the relevant standards of cement concrete, the polycarboxylate water reducer with the structure shown in formula I prepared in Example 2 was tested for relevant performance, and the results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com