Expanded halogen-free flame-retardant EVA-based composite material and preparation method thereof

A composite material and an intumescent technology, which is applied in the field of intumescent halogen-free flame retardant EVA-based composite materials and their preparation, can solve the problems of flame retardant efficiency or environmental protection requirements that cannot meet the performance requirements of new flame retardant composite materials, and can achieve particle size. Small diameter, improved flame retardant performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

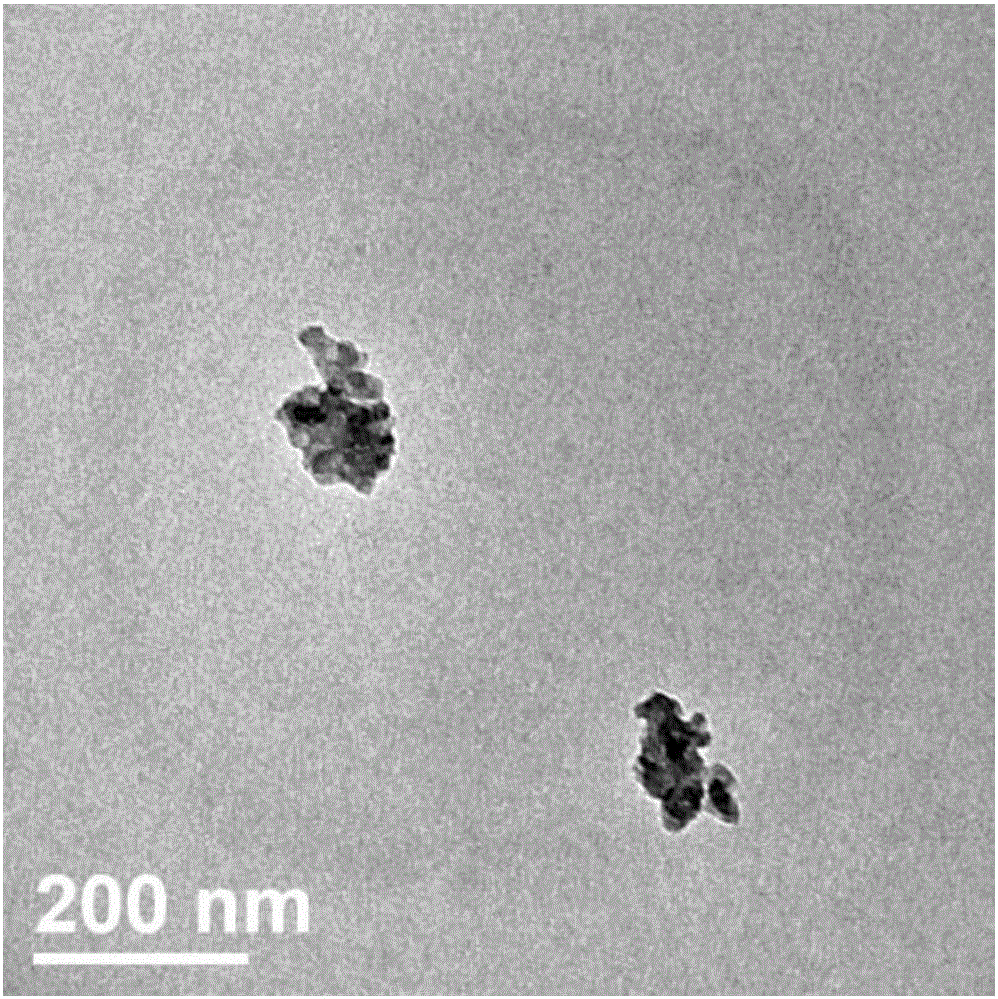

[0022] Weigh 50g of EVA pellets, 12.5g of starch, 35.5g of ammonium polyphosphate, and 2g of nitrogen-based trimethylene zirconium phosphate. After mixing the above pellets evenly, at a temperature of 195°C and a screw speed of 25r / min, the Twin-screw extruder melts and blends in melting, makes the EVA-based composite material of the present invention, and its electron microscope figure is as follows: figure 1 As shown, the particle size of the prepared product is smaller, which is nanometer size. After testing, the limiting oxygen index is 28.5%, the UL-94 test reaches V-0 level, and there is no droplet phenomenon. The tensile strength of the composite is 9.17 MPa, and the elongation at break is 115.6%.

Embodiment 2

[0024] Weigh 50g of EVA pellets, 12.5g of starch, 34.5g of ammonium polyphosphate, and 3g of zirconium nitrogen trimethylene phosphate. After mixing the above pellets evenly, at a temperature of 195°C and a screw speed of 25r / min, Melt-in-melt blending in a twin-screw extruder to prepare the EVA-based composite material of the present invention. After testing, the limiting oxygen index is 30.0%, and the UL-94 test reaches V-0 level, and there is no droplet phenomenon. The tensile strength of the composite is 10.29 MPa, and the elongation at break is 104.9%.

Embodiment 3

[0026] Weigh 50g of EVA pellets, 12.5g of starch, 33.5g of ammonium polyphosphate, and 3g of zirconium nitrogen trimethylene phosphate. After mixing the above pellets evenly, at a temperature of 195°C and a screw speed of 25r / min, the Melt-in-melt blending in a twin-screw extruder to prepare the EVA-based composite material of the present invention. After testing, the limiting oxygen index is 31.0%, the UL-94 test reaches V-0 level, and there is no droplet phenomenon. The tensile strength of the composite is 9.54 MPa, and the elongation at break is 101.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com