Liquid-state die forging process for cam shaft gear for automobile engine

A technology for camshaft gears and automobile engines, which is applied in the manufacture of tools, metal processing equipment, coatings, etc. It can solve problems such as the production process of camshaft gears that have not been mentioned, and achieve reasonable design of process steps, improve efficiency, and improve material utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the manufacturer's conditions, and the unspecified implementation conditions are usually conventional experimental conditions.

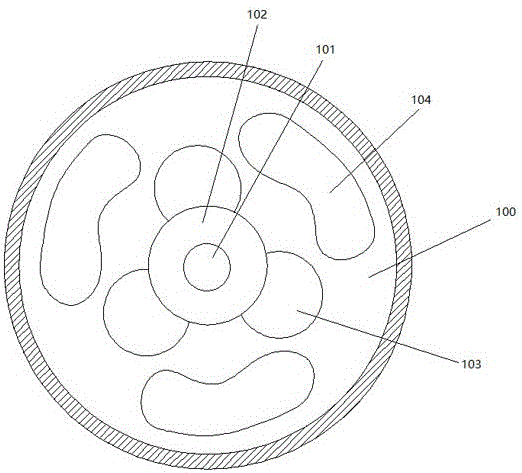

[0045] see figure 1 , the camshaft gear obtained by the liquid die forging process of a camshaft gear for an automobile engine provided by the present invention includes a disc 100, a through hole 101 is opened in the middle, and a ring 102 is set on the surface of the through hole 101, and the outer circumference of the ring 102 is Three arc-shaped bosses 103 are equidistantly spaced, and three openings 104 are equidistantly spaced along the circumference of the through hole 101 on the surface of the disc 100 .

[0046] The invention provides a liquid die forging process for a camshaft gear used in an automobile engine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com