Method for preparing composite nanofiber tissue engineering scaffold based on graphene oxide

A technology of tissue engineering scaffolds and composite nanofibers, applied in fiber treatment, animal fibers, non-woven fabrics, etc., to achieve the effect of promoting adhesion, good biocompatibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method based on graphene oxide composite nanofiber tissue engineering scaffold, the specific steps are:

[0045] 1. Put the tussah silk in the environment of 95~100℃, 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, put the obtained tussah silk fibroin protein solution into a dialysis bag with a molecular weight cut-off of 8-10KDa, and use Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

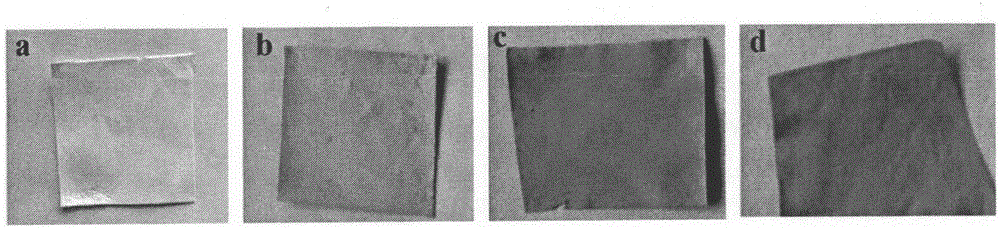

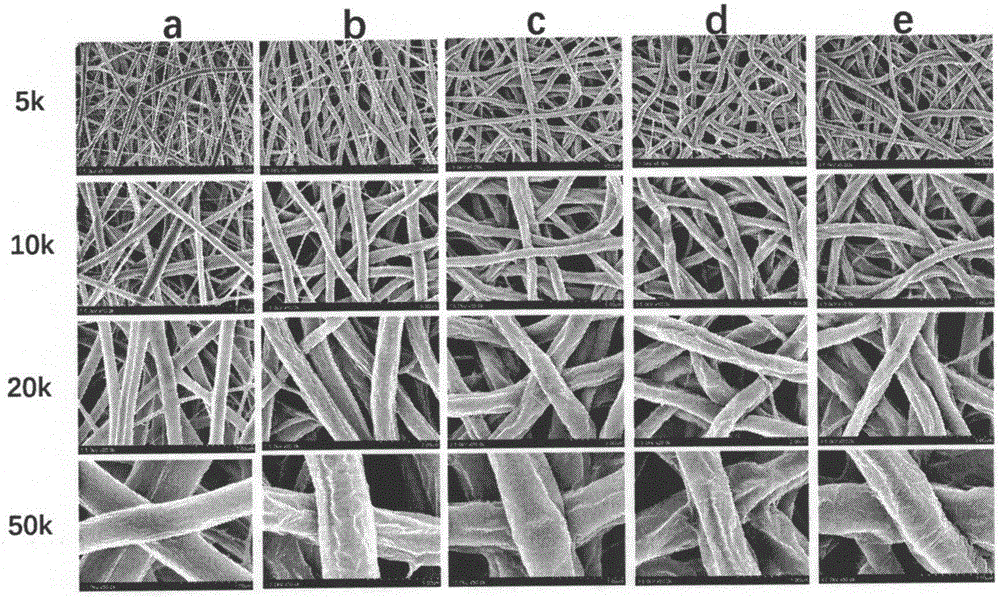

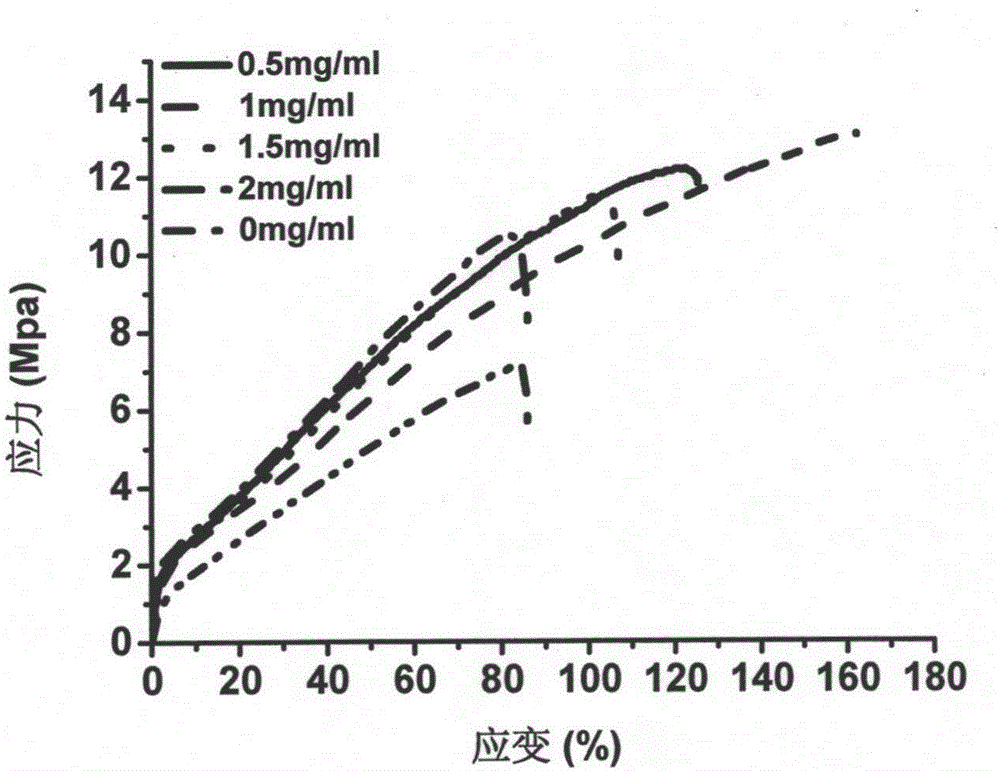

[0046] 2. Weigh 0.125g of silk fibroin and 0.375g of high molecular polymer, dissolve them in 5ml of hexafluoroisopropanol, and magnetically stir at a certain rate until completely dissolved to obtain a spinning fiber with a concentration of 10% (w / v). liquid. Perform ele...

Embodiment 2

[0049] A preparation method based on graphene oxide composite nanofiber tissue engineering scaffold, the specific steps are:

[0050] 1. Place the tussah silk at 95~100℃ 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, put the obtained tussah silk fibroin protein solution into a dialysis bag with a molecular weight cut-off of 8-10KDa, and use Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

[0051] 2. Weigh 0.125g of silk fibroin and 0.375g of high molecular polymer, dissolve them in 5ml of hexafluoroisopropanol, and magnetically stir at a certain rate until completely dissolved to obtain a spinning fiber with a concentration of 10% (w / v). liquid. Perform electrospinning and w...

Embodiment 3

[0054] A preparation method based on graphene oxide composite nanofiber tissue engineering scaffold, the specific steps are:

[0055] 1. Put the tussah silk in the environment of 95~100℃, 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, put the obtained tussah silk fibroin protein solution into a dialysis bag with a molecular weight cut-off of 8-10KDa, and use Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

[0056] 2. Weigh 0.125g of silk fibroin and 0.375g of high molecular polymer, dissolve them in 5ml of hexafluoroisopropanol, and magnetically stir at a certain rate until completely dissolved to obtain a spinning fiber with a concentration of 10% (w / v). liquid. Perform ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com