A kind of negative electrode composite material and its preparation method and application

A composite material and negative electrode technology, applied in the application field of lithium ion batteries, can solve the problems of insufficient rate performance, poor electrode cycle stability, high raw material prices, etc., and achieve good cycle stability, low raw material cost, and electrochemical performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

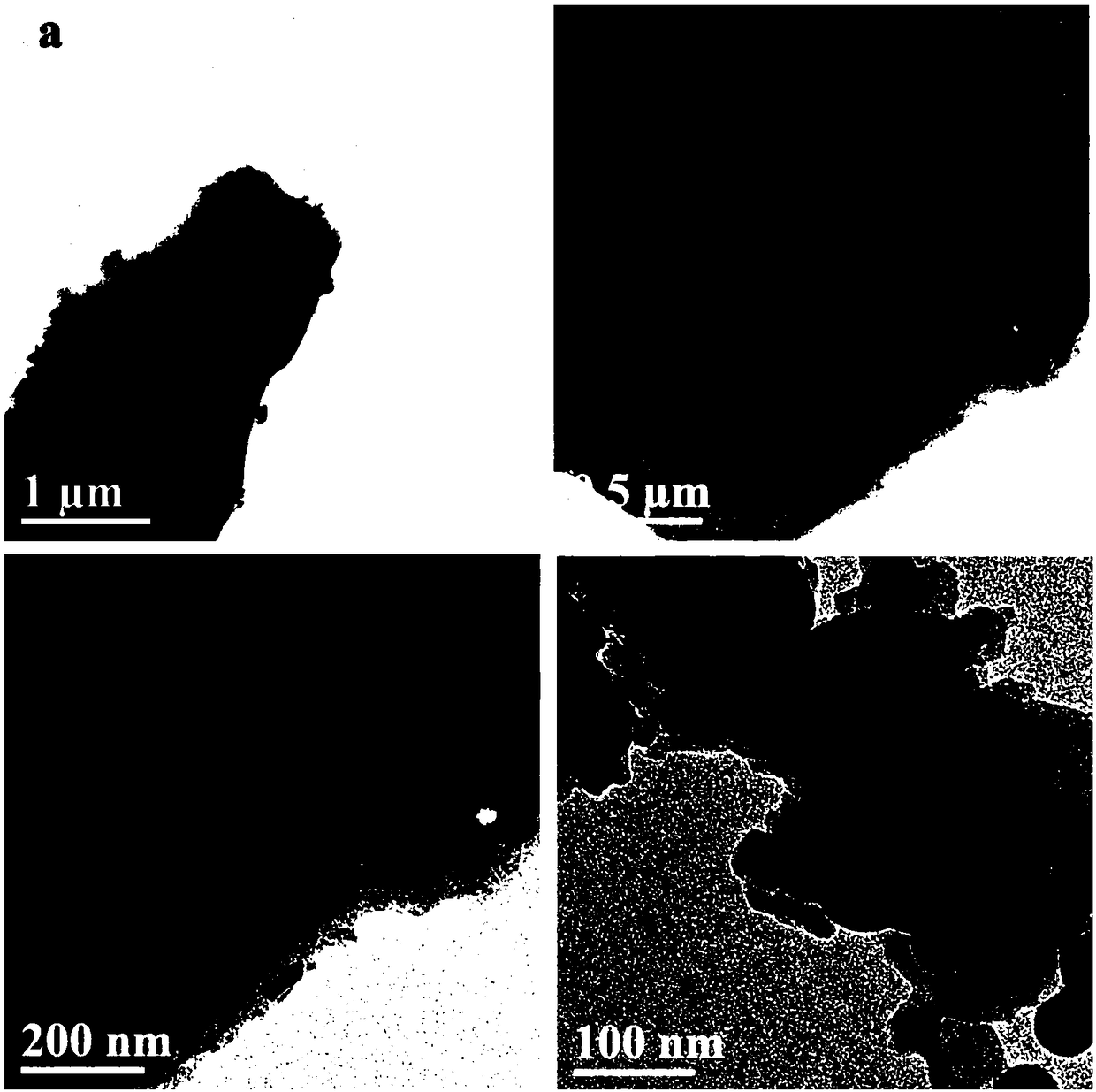

[0032] The 100nm Si powder was sintered in a muffle furnace at a high temperature of 500°C for 1h. Take 0.12g of sintered silicon powder and disperse it in 20mL of deionized water and ultrasonically uniformly, then disperse 0.2g of P123 and 1g of pea flour in it, stir evenly at room temperature, then heat to paste, put it in the refrigerator and freeze for 6h. Then, freeze-drying and sintering with Ar gas at 600 degrees for 3 hours to prepare the target composite electrode material.

[0033] The ground composite material is fully ground and used as the negative electrode material of the lithium ion electrode, mixed with carbon black and carboxymethyl cellulose in a ratio of 70:15:15 parts by weight, and the film is dried in vacuum at 70°C for 6 hours to prepare A composite electrode for a lithium ion battery is obtained. The composite electrode was placed in the 2025 battery case, the lithium sheet was used as the counter electrode, the polyethylene film was used as the diaphrag...

Embodiment 2

[0036] The 100nm Si powder was sintered in a muffle furnace at a high temperature of 500°C for 1h. Take 0.01g of graphene oxide and disperse it in 40mL of deionized water, and then disperse 0.02g of sintered silicon powder in the above mixed solution. After sonication, disperse 0.4g of F127 and 1g of pea flour in it, stir well at room temperature, and then Heat to a paste, put in the refrigerator and freeze for 6h. Then, freeze-drying, 900 degrees Ar gas sintering for 2 hours to prepare the target composite electrode material.

[0037] The obtained composite material has been examined by SEM and TEM, and the structure is basically similar to that of the material obtained in Example 1.

[0038] The ground composite material is fully ground and used as the negative electrode material of the lithium ion electrode, mixed with carbon black and carboxymethyl cellulose in a ratio of 70:15:15 parts by weight, and the film is dried in vacuum at 70°C for 6 hours to prepare A composite elec...

Embodiment 3

[0040] The 100nm Si powder was sintered in a muffle furnace at a high temperature of 500°C for 1h. Take 0.1g carboxylated multi-arm carbon nanotubes and disperse them in 30mL deionized water uniformly by ultrasonic, then disperse 0.2g sintered silicon powder in the above mixed solution, and disperse 0.2g P123 and 1g pea powder in the mixed solution after uniform ultrasonication. Stir evenly at room temperature, then heat to a paste, put it in the refrigerator and freeze for 6 hours. Then, freeze-drying, 500 degrees Ar gas sintering for 6 hours to prepare the target composite electrode material.

[0041] The obtained composite material has been examined by SEM and TEM, and the structure is basically similar to that of the material obtained in Example 1.

[0042] The ground composite material is fully ground and used as the negative electrode material of the lithium ion electrode, mixed with carbon black and carboxymethyl cellulose in a ratio of 70:15:15 parts by weight, and the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com