Preparation method and application of tentacle type amino acid supported ionic liquid

An ionic liquid, amino acid type technology, applied in chemical instruments and methods, ion exchange, ion exchange regeneration, etc., can solve the problems of increased solid loading, limited carrier surface area, etc., and achieve the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

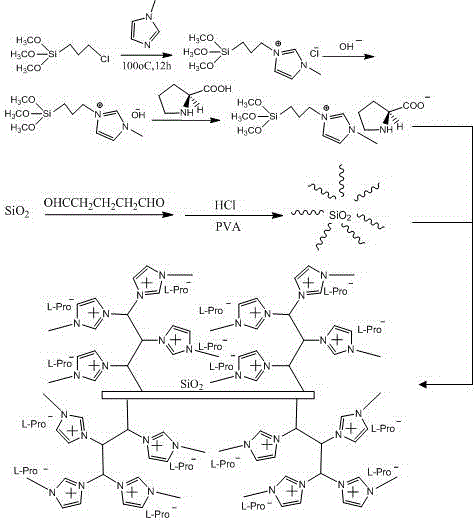

[0016] Implementation Example 1: The preparation method of L-proline methylimidazolium ionic liquid

[0017] (1) Weigh 0.1mol of γ-chloropropyltrimethoxysilane into a 100mL round bottom flask, add 0.12mol of N-methylimidazole, heat up to 80°C under nitrogen protection, and reflux for 16 hours to form a light yellow viscous liquid. The product was washed 4 times with ethyl acetate to remove unreacted N-methylimidazole, then washed 4 times with anhydrous ether, the solvent was distilled off under reduced pressure, and the product was vacuum-dried at 60°C for 36 hours. (2) Weigh 0.05 mol of the product of step (1) in a beaker, add 50 mL of absolute ethanol to dissolve it, and transfer the dissolved solution to a pretreated strongly basic anion exchange resin (201×7 -717 type) packed column (the amount of resin is 7 times the molar exchange capacity, and the height of the packing is 300mm), the flow rate of the effluent is controlled not to exceed 2 drops per second, and ethanol i...

Embodiment 2

[0018] Implementation example 2: the preparation method of tentacled silica gel intermediate

[0019] Weigh 3.0 g of silica gel and place it in a 100 mL round bottom flask. Add an appropriate amount of water-dispersible silica gel, add 15mL of hydrochloric acid and 6.0g of glutaraldehyde aqueous solution with a mass fraction of 50% into the flask successively with a constant pressure dropping funnel, and react at room temperature for 3h. After that, 20 mL of polyvinyl alcohol (polymerization degree 1700, alcoholysis rate 99%) solution with a mass fraction of 15% was added dropwise, and the reaction was stirred at 35°C for 6 h. The product was washed with deionized water until neutral, dried and stored in a desiccator. The product is white tentacle-type silica gel powder.

Embodiment 3

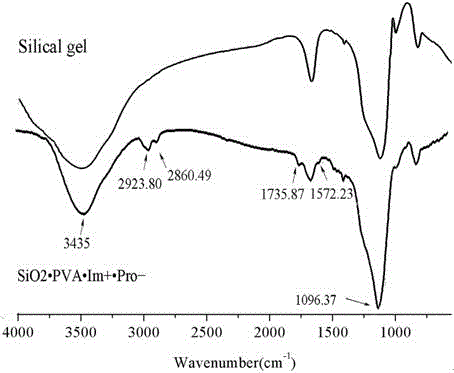

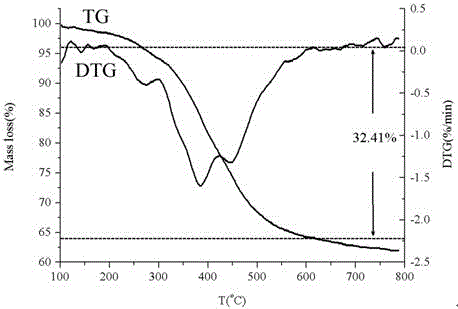

[0020] Implementation Example 3: The preparation method of antenna-type L-proline methylimidazole immobilized ionic liquid

[0021] Take 3.0 g of tentacle-type silica gel powder and disperse it in 30 mL of acetonitrile, and add 0.03 mol of the product of step (4). 80 ° C reflux reaction for 12h. The product was washed three times with deionized water to remove unreacted L-proline imidazolium ionic liquid, and vacuum-dried at 60° C. for 8 hours to obtain an antenna-type amino acid immobilized ionic liquid. The final product is light yellow solid powder, and the immobilization capacity of ionic liquid is 0.3g ionic liquid / g adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com