Method for preparing organic fertilizer by using straw decomposition agent

A straw decomposing agent and bio-organic fertilizer technology, which is applied in the preparation of organic fertilizer, organic fertilizer, bio-organic part treatment and other directions, can solve the problems of crop quality decline, damage to soil structure, soil compaction, etc., to reduce the demand for nutrients, The effect of high fertilizer content and easy absorption by crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

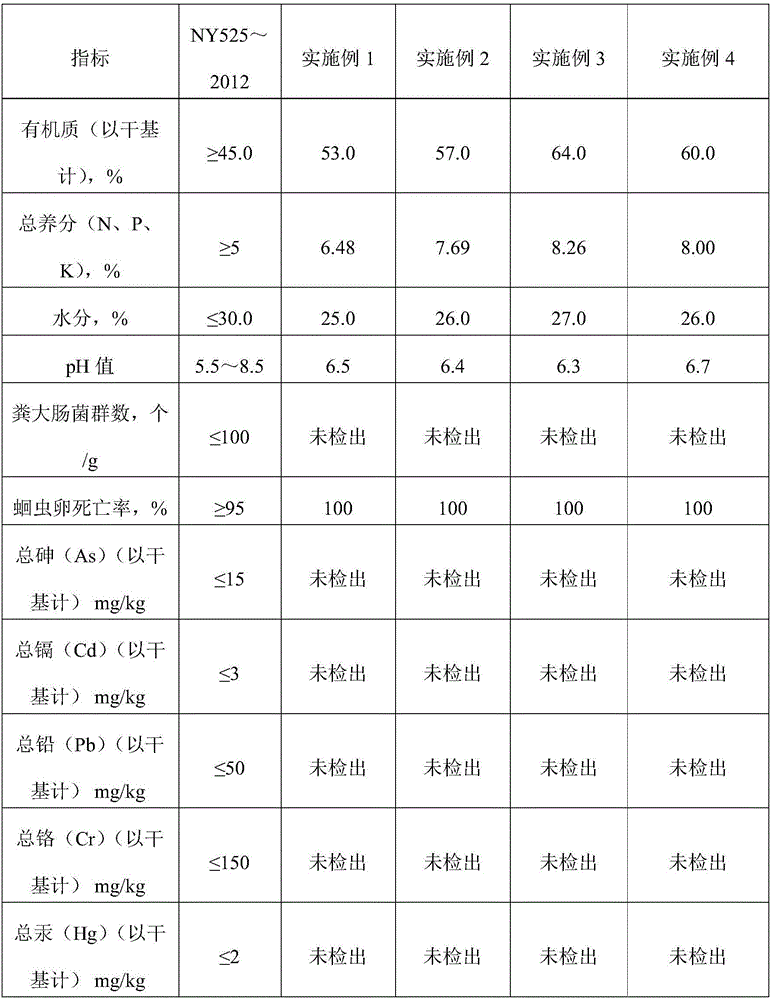

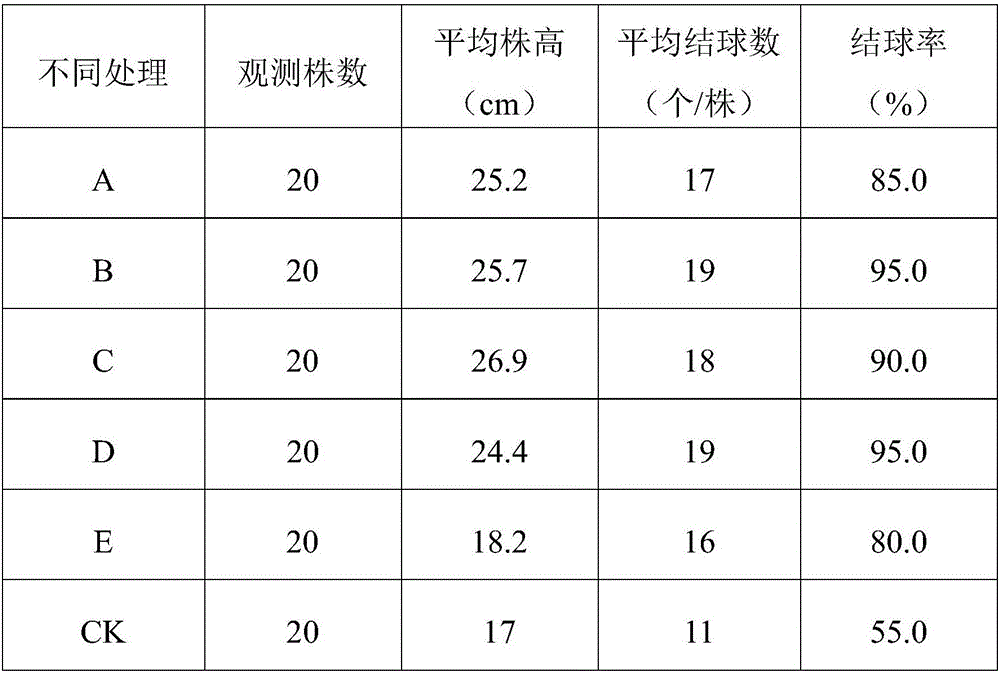

Examples

Embodiment 1

[0024] Preparation of straw decomposing agent: after respectively culturing Bacillus subtilis, Bacillus licheniformis, yeast and Aspergillus oryzae at 36°C for 48 hours, the Bacillus subtilis, the Bacillus licheniformis, the yeast and the Said Aspergillus oryzae is carried out expansion culture respectively, the bacterial strain of expansion culture is mixed according to mass percentage Bacillus subtilis bacterial strain 30%, Bacillus licheniformis bacterial strain 25%, saccharomycetes bacterial strain 25%, Aspergillus oryzae bacterial strain 20%, wherein, the total effective number of live bacteria It is 1.57×108 cells / mL, and the decomposing agent cellulase activity reaches 55u / ml (g). After being mixed, it is added to a fermentation medium containing corn soaking water for cultivation to obtain a composite bacterial liquid, which is concentrated and then spray-dried to obtain a straw decomposing agent.

[0025] Mixed material: crush corn stalks into 5cm pieces and mix them ...

Embodiment 2

[0028] Preparation of straw decomposing agent: After culturing Bacillus subtilis, Bacillus licheniformis, yeast and Aspergillus oryzae under 33°C for 72 hours, the Bacillus subtilis, Bacillus licheniformis, yeast and Aspergillus oryzae carries out expanded culture respectively, the bacterial strain of expanded culture is mixed according to mass percentage Bacillus subtilis bacterial strain 27%, Bacillus licheniformis bacterial strain 23%, saccharomycetes bacterial strain 23%, Aspergillus oryzae bacterial strain 27%, wherein, the total effective number of viable bacteria is 1.90×10 8 per mL, decomposing agent cellulase activity up to 59u / ml (g). After being mixed, it is added to a fermentation medium containing corn soaking water for cultivation to obtain a composite bacterial liquid, which is concentrated and then spray-dried to obtain a straw decomposing agent.

[0029] Mixed material: crush corn stalks into 7cm pieces and mix them with livestock and poultry manure at a weig...

Embodiment 3

[0032] Preparation of straw decomposing agent: after respectively culturing Bacillus subtilis, Bacillus licheniformis, yeast and Aspergillus oryzae at 35°C for 56 hours, the Bacillus subtilis, the Bacillus licheniformis, the yeast and the Said Aspergillus oryzae is carried out expanding culture respectively, the bacterial strain of expanding culture is mixed according to mass percentage Bacillus subtilis bacterial strain 25%, Bacillus licheniformis bacterial strain 20%, saccharomycetes bacterial strain 20%, Aspergillus oryzae bacterial strain 35%, wherein, the total effective number of live bacteria 1.90×10 8 per mL, decomposing agent cellulase activity up to 65u / ml (g). After being mixed, it is added to a fermentation medium containing corn soaking water for cultivation to obtain a composite bacterial liquid, which is concentrated and then spray-dried to obtain a straw decomposing agent.

[0033]Mixed materials: crush corn stalks into 5cm pieces and mix them with livestock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com