Device and method for continuous cultivation and production of lysine

A technology for producing lysine and lysine, which is applied in biochemical equipment and methods, biological material sampling methods, biochemical cleaning devices, etc., can solve the problems of contamination, burden, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

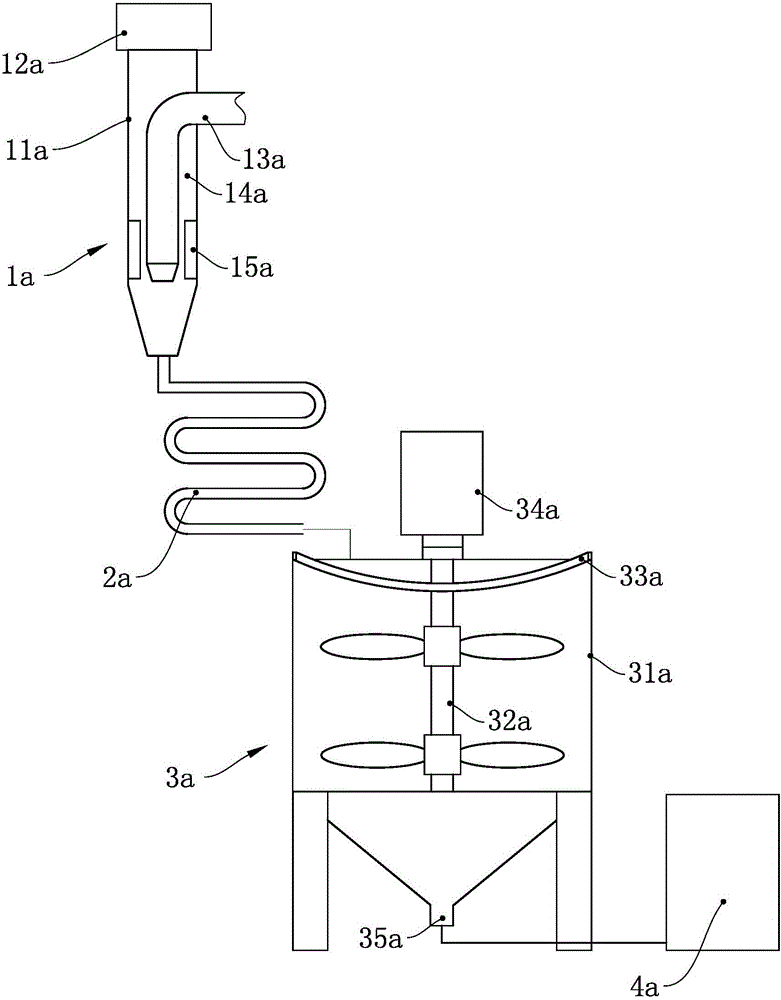

Embodiment 1

[0083] A method for continuously cultivating and producing lysine, comprising the steps of:

[0084] (1) Uninterrupted cultivation: After the first-level seed tank is cultivated to a certain bacterial concentration, it is transferred to the second-level seed tank for cultivation according to a certain inoculation amount, and the first-level seed tank is supplemented with a certain volume of medium for the first-level seed tank to continue the cultivation , according to the growth time of the first-level seed tank, the second-level seed tank inoculation is carried out after reaching the required bacterial concentration, and the continuous cycle is continuously cultivated; in this embodiment, the OD of the bacteria in the first-level seed tank is maintained at 0.45, and the second-level seed tank is maintained. The OD of the bacteria in the seed tank is 0.9;

[0085] (2) Uninterrupted fermentation: Transfer the bacterial liquid obtained from the cultivation of the secondary seed...

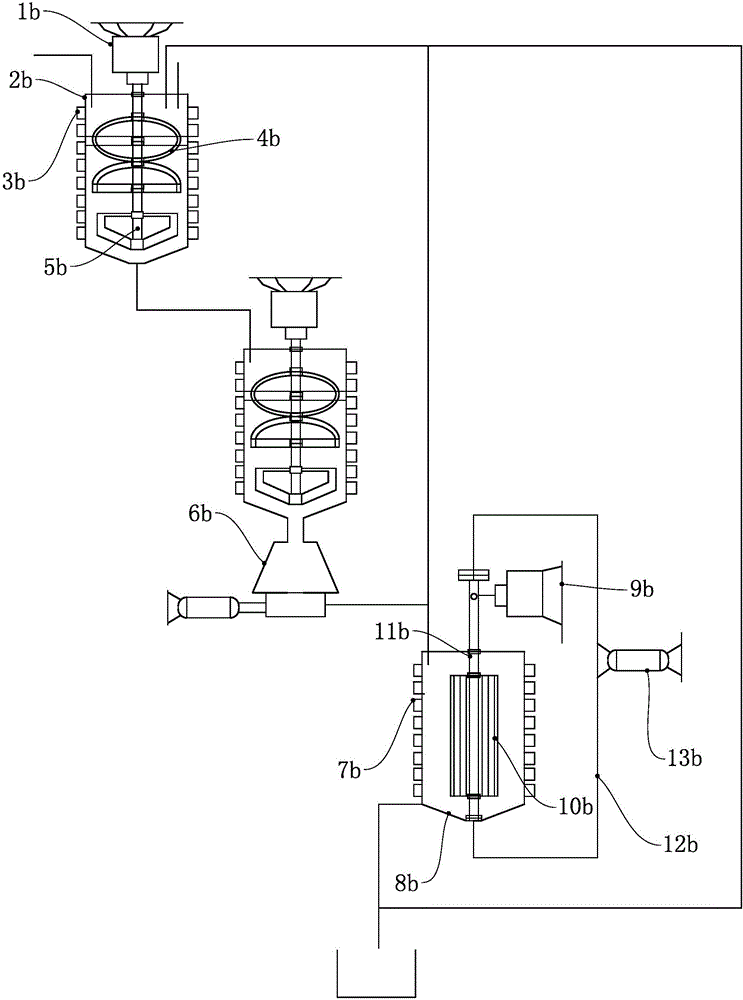

Embodiment 2

[0094] A method for continuously cultivating and producing lysine, comprising the steps of:

[0095] (1) Uninterrupted cultivation: After the first-level seed tank is cultivated to a certain bacterial concentration, it is transferred to the second-level seed tank for cultivation according to a certain inoculation amount, and the first-level seed tank is supplemented with a certain volume of medium for the first-level seed tank to continue the cultivation , according to the growth time of the first-level seed tank, the second-level seed tank inoculation is carried out after reaching the required cell concentration, and the continuous circulation is cultivated successively; in this embodiment, the OD of the bacteria in the first-level seed tank is maintained at 0.65, and the second-level seed tank is maintained. The OD of the bacteria in the seed tank is 1.1;

[0096] (2) Uninterrupted fermentation: Transfer the bacterial liquid obtained from the cultivation of the secondary see...

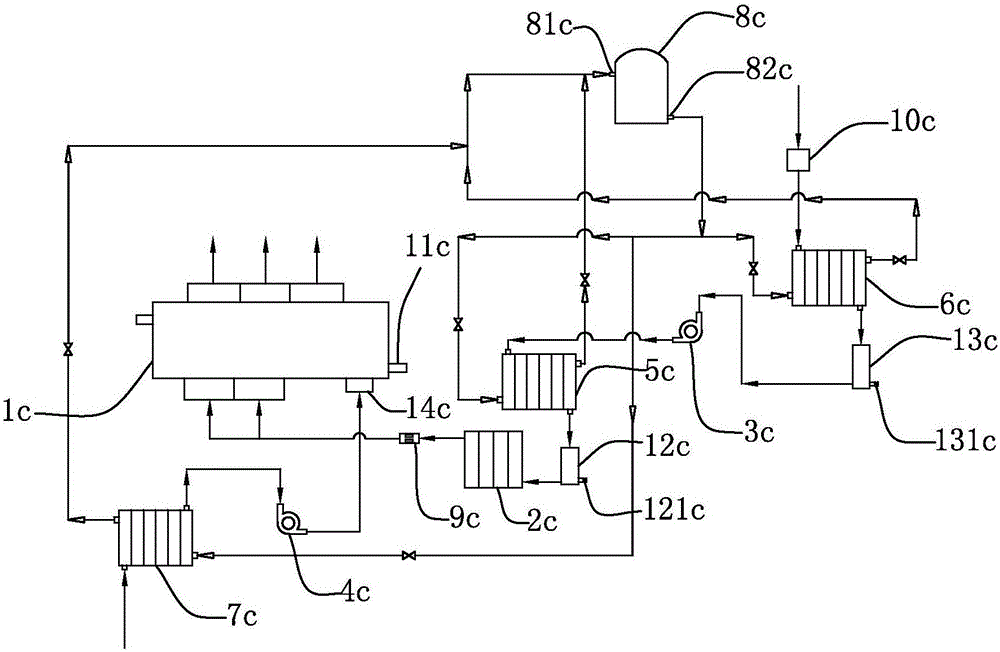

Embodiment 3

[0105] A method for continuously cultivating and producing lysine, comprising the steps of:

[0106] (1) Uninterrupted cultivation: After the first-level seed tank is cultivated to a certain bacterial concentration, it is transferred to the second-level seed tank for cultivation according to a certain inoculation amount, and the first-level seed tank is supplemented with a certain volume of medium for the first-level seed tank to continue the cultivation , according to the growth time of the first-level seed tank, the second-level seed tank inoculation is carried out after reaching the required cell concentration, and the continuous circulation is cultivated successively; in this embodiment, the OD of the bacteria in the first-level seed tank is maintained at 0.5, and the second-level The OD of the bacteria in the seed tank is 1;

[0107] (2) Uninterrupted fermentation: Transfer the bacterial liquid obtained from the cultivation of the secondary seed tank to the first fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com