Preparation and treating methods and application of fermentation broth of 1,3-propylene glycol, preparation method for water-soluble fertilizer, and water-soluble fertilizer

A treatment method and technology of fermented liquid, applied in the direction of application, sewage/sludge fertilizer, potash fertilizer, etc., can solve the problems of insufficient environmental protection and thoroughness, and achieve the effects of improving quality, increasing fertilizer efficiency, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

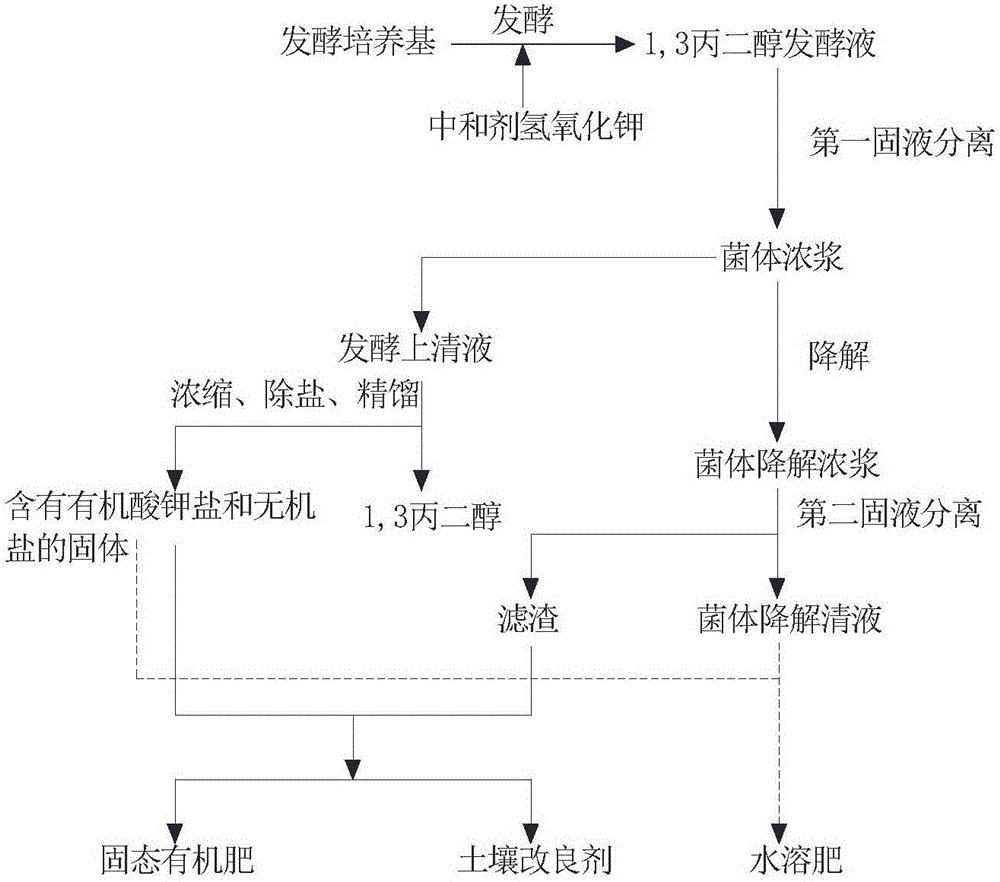

Method used

Image

Examples

Embodiment approach

[0035] According to the present invention, in step 2), the separation method for separating 1,3-propanediol and the solid containing organic acid potassium salt and inorganic salt from the fermentation supernatant can be a conventional choice in the art. For example, concentration, desalting and rectification may be performed in sequence. According to a preferred embodiment of the present invention, the method for separating the fermentation supernatant comprises the following steps: by concentrating the fermentation supernatant, and then feeding it to a scraped film evaporator, obtaining Liquids of 1,3-propanediol and 2,3-butanediol, glycerin and water are obtained from the bottom of the tower as solids containing potassium salts of organic acids and inorganic salts. The liquid containing 1,3-propanediol, 2,3-butanediol, glycerin and water is rectified to obtain 1,3-propanediol.

[0036] In the present invention, the inorganic salt can be nitrogen salt and / or phosphorus salt...

Embodiment 1

[0055] This embodiment is used to illustrate the preparation and processing method and application of the fermentation liquid of 1,3-propanediol provided by the present invention and the preparation method of water-soluble fertilizer and water-soluble fertilizer

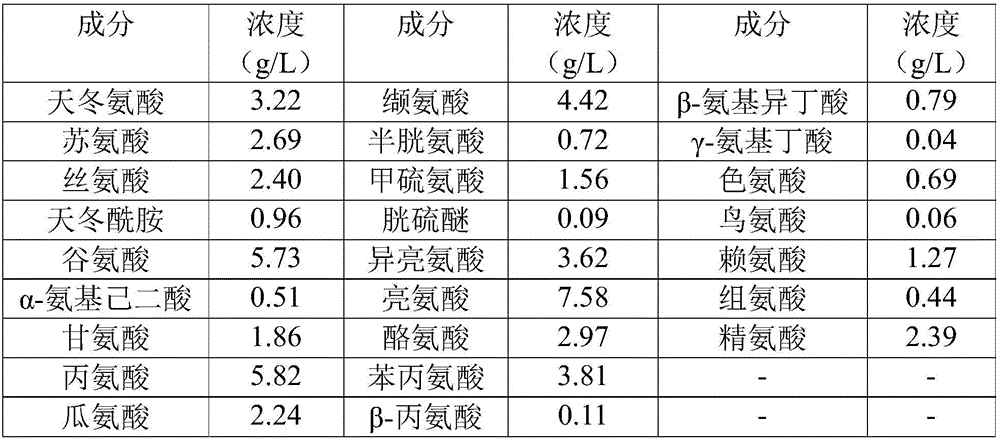

[0056] (1-1) Preparation method of fermented liquid of 1,3-propanediol

[0057] Klebsiella pneumoniae (Klebsiella) was inoculated into a fermenter containing a fermentation medium under aseptic conditions for fermentation. The fermentation temperature was 30° C., the stirring speed was 250 rpm, and the ventilation volume was 2.0 VVM. Use potassium hydroxide all (100% by weight) to replace sodium hydroxide to adjust the pH of the fermented liquid to be 6.5, when the concentration of 1,3-propanediol in the fermented liquid no longer rises, stop fermentation, obtain 1,3-propanediol fermented liquid, Its composition is listed in Table 1.

[0058] (1-2) The processing method of 1,3-propanediol fermentation broth

[0059...

Embodiment 2

[0080] This embodiment is used to illustrate the preparation and processing method and application of the fermentation liquid of 1,3-propanediol provided by the present invention and the preparation method of water-soluble fertilizer and water-soluble fertilizer

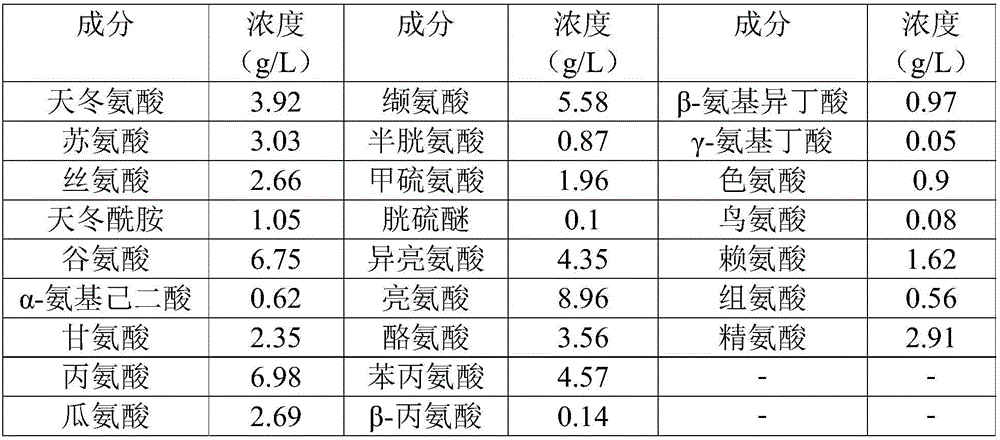

[0081] (2-1) Preparation method of fermented liquid of 1,3-propanediol

[0082] Klebsiella pneumoniae (Klebsiella) was inoculated into a fermenter containing a fermentation medium under aseptic conditions for fermentation. The fermentation temperature was 37° C., the stirring speed was 150 rpm, and the ventilation volume was 1.0 VVM. Use potassium hydroxide part (potassium hydroxide accounts for 75% by weight of neutralizing agent) to replace sodium hydroxide to adjust the pH of fermented liquid to be 6, when the concentration of 1,3-propanediol no longer rises in the fermented liquid, stop fermentation, obtain 1 , 3-propanediol fermentation broth, its composition is listed in table 5.

[0083] (2-2) The processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com