Preparation method of polymer film with hydrophilic and anti-fouling performance

A technology of polymer film and amphiphilic polymer, which is applied in the field of preparation of polymer film, can solve the problem that zwitterionic polymer cannot be dissolved, and achieve the effect of improving hydrophilicity, anti-fouling property and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

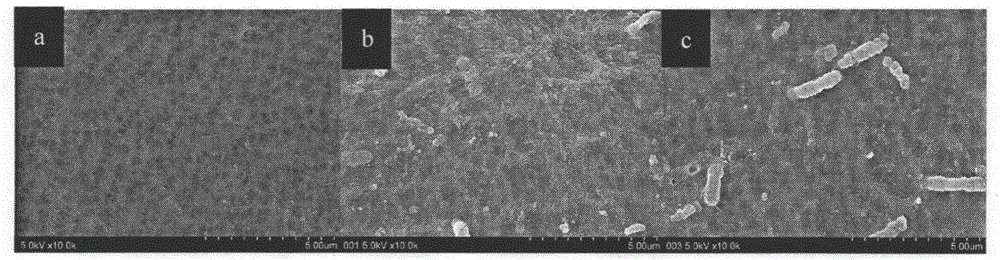

Examples

Embodiment 1

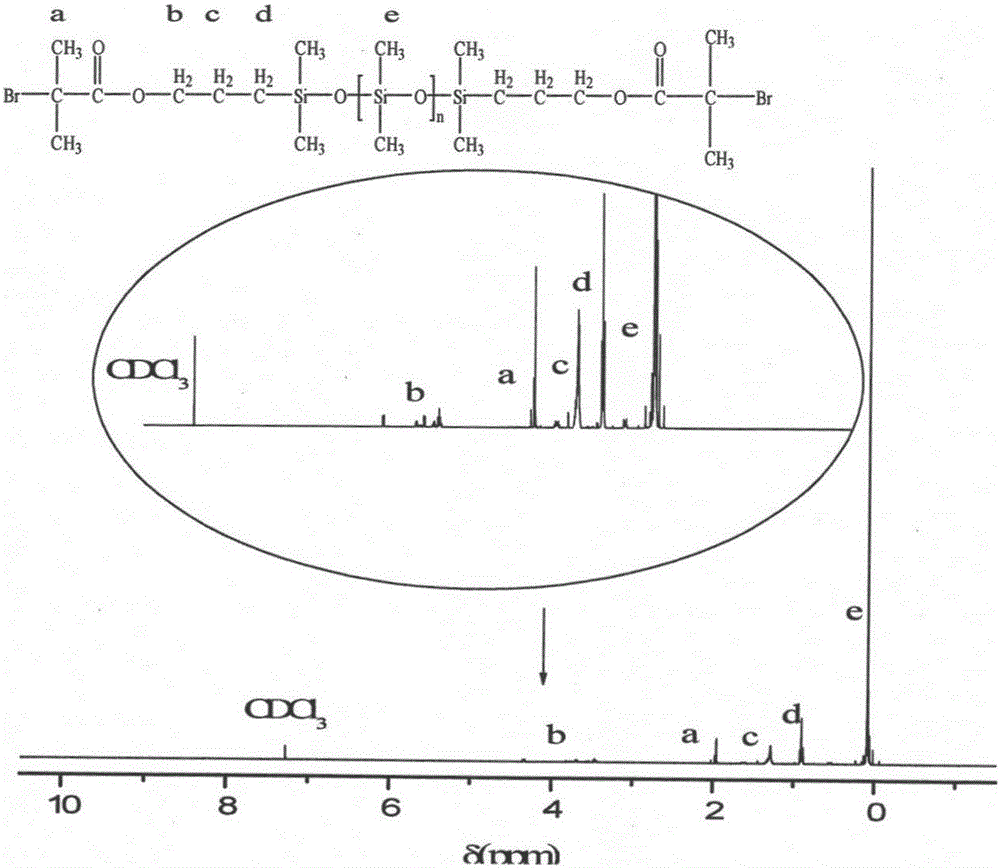

[0057] A kind of preparation method of amphiphilic polymer, concrete steps are:

[0058] In a 250mL three-necked flask, add 30g (7.5mmol) hydroxypropyl silicone oil (molecular weight: 4000g / mol), 1.6g (15.5mmol) triethylamine and 40ml THF, place in an ice-water bath, and pass through the flask for 10min. 2 Air to remove air. A mixture of 3.5g (15mmol) 2-bromoisobutyryl bromide and 20ml tetrahydrofuran was slowly added dropwise in a constant pressure dropping funnel, and the addition was completed within about 1h. The ice-water bath was removed, and the reaction was continued for 16 h at room temperature. After the reaction is complete, remove the insoluble ammonium salt by suction filtration with a Buchner funnel, spin evaporate the filtered solution to remove THF, then add n-hexane to dissolve, wash 3 times with deionized water in the separatory funnel, and remove the lower layer after layering. Dissolved in aqueous solution of triethylamine salt. Add anhydrous magnesium s...

Embodiment 2

[0061] A kind of preparation method of amphiphilic polymer, concrete steps are:

[0062]In a 250mL three-necked flask, add 30g of hydroxypropyl silicone oil (molecular weight: 4000g / mol), 3.2g of triethylamine and 40ml of THF, place in an ice-water bath, and pass argon gas into the flask for 60min to remove the air. Slowly add a mixture of 7g of 2-bromoisobutyryl chloride and 40ml of tetrahydrofuran dropwise in a constant pressure dropping funnel, and finish adding within about 1h. The ice-water bath was removed, and the reaction was continued for 24 h at room temperature. After the reaction is complete, remove the insoluble ammonium salt by suction filtration with a Buchner funnel, spin evaporate the filtered solution to remove THF, then add n-hexane to dissolve, wash 3 times with deionized water in the separatory funnel, and remove the lower layer after layering. Dissolved in aqueous solution of triethylamine salt. Add anhydrous magnesium sulfate to the obtained upper laye...

Embodiment 3

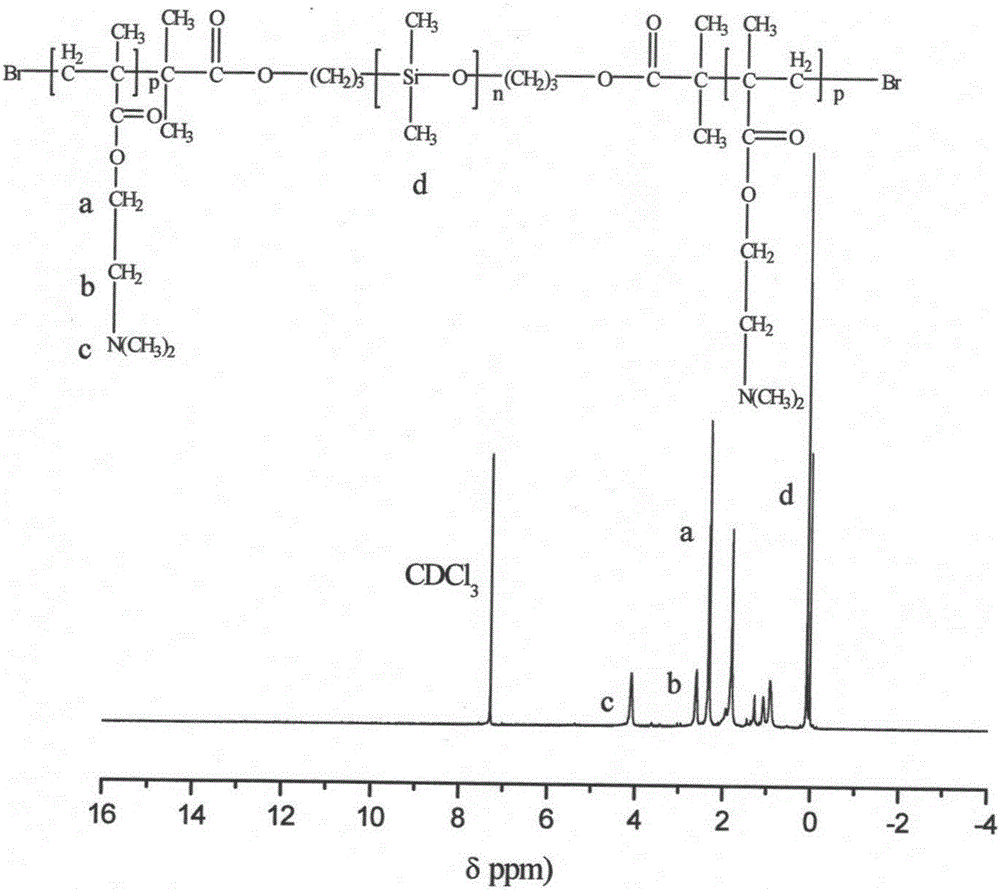

[0065] A kind of preparation method of amphiphilic polymer, concrete steps are:

[0066] (1) In a 250mL three-necked flask, add 30g of hydroxypropyl silicone oil (molecular weight 4000g / mol), 3.2g of triethylamine and 40ml of THF, put it in an ice-water bath, and pass nitrogen into the flask for 20min to remove the air. Slowly add a mixture of 7g of 2-bromoisobutyryl chloride and 40ml of tetrahydrofuran dropwise in a constant pressure dropping funnel, and finish adding within about 1h. The ice-water bath was removed, and the reaction was continued for 48 h at room temperature. After the reaction is complete, remove the insoluble ammonium salt by suction filtration with a Buchner funnel, spin evaporate the filtered solution to remove THF, then add n-hexane to dissolve, wash 3 times with deionized water in the separatory funnel, and remove the lower layer after layering. Dissolved in aqueous solution of triethylamine salt. Add anhydrous magnesium sulfate to the obtained upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com