A process for directly producing hydrogen sulfide by cracking hydrogen-rich gas with methanol/liquid ammonia

A hydrogen sulfide and liquid ammonia technology, applied in the production of hydrogen sulfide, sulfur compounds, hydrogen, etc., can solve the problems of large investment, high operating cost, and low resource utilization rate, shorten the process flow, reduce overall investment, and reduce resources Effect of Utilization Ratio Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

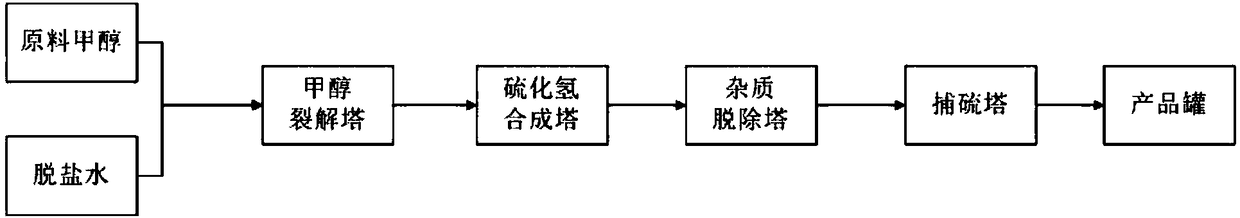

[0042] A process for directly producing hydrogen sulfide by cracking hydrogen-rich gas with methanol / liquid ammonia, comprising the following steps:

[0043] 1) Make methanol and water into an aqueous solution at a volume ratio of 1:1, preheat the resulting aqueous solution to 80°C, and then vaporize it through the evaporator, and the vaporized mixed steam enters the superheater and raises the temperature to 200°C;

[0044] 2) The mixed steam of methanol and water after preheating enters cracking tower, and the control temperature in cracking tower is 250 ℃, and packing catalyst is commercially available Cu-Zn-Al methanol reforming catalyst, controls the contact time of steam and catalyst is 20s, and after the reaction ends, a CO 2 , CO, CH 4 Hydrogen-rich gas with a small amount of raw material steam;

[0045] 3) The generated hydrogen-rich gas enters the hydrogen sulfide synthesis tower, which is a fixed-bed reactor, and reacts with the liquid sulfur entering it in the hyd...

Embodiment 2

[0049]A preparation process for hydrogen sulfide, comprising the steps of:

[0050] 1) Preheat the liquid ammonia to 60°C, and then vaporize it through the evaporator, and the vaporized mixed steam enters the superheater to preheat to 600°C;

[0051] 2) The mixed steam of preheated ammonia and water vapor enters the cracking tower, the temperature in the cracking tower is controlled at 500°C, the filled catalyst is a commercially available iron-based ammonia synthesis catalyst, and the contact time between the steam and the catalyst is controlled to be 15s. After the end of the reaction, N 2 hydrogen-rich gas;

[0052] 3) The generated hydrogen-rich gas enters the hydrogen sulfide synthesis tower, which is a fixed-bed reactor, and reacts with the liquid sulfur entering it in the hydrogen sulfide synthesis tower. The reaction temperature is controlled at 400°C. The catalyst in the synthesis tower It is nickel loaded on alumina, the loading of nickel is 10wt%, and the loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com