Method for preparing 9, 9-bis(4-(2-hydroxyethoxy)phenyl)fluorene from ethylene oxide

A technology of ethylene oxide catalysis and ethylene oxide, which is applied in the preparation of ether from alkylene oxide, ether preparation, organic chemistry, etc. It can solve the problems of increased environmental burden, low reaction yield, and reduced product color and purity. , to achieve the effects of easy refining and purification, simple synthesis and operation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

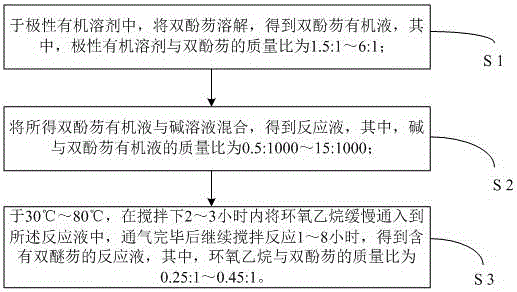

Method used

Image

Examples

Embodiment 1

[0030] Example 1 of the present invention provides a method for preparing bis-ether fluorene catalyzed by ethylene oxide, which is prepared according to the following steps:

[0031] Add 35 grams of bisphenol fluorene to a 500 ml pressure reactor, add 200 ml of absolute ethanol, add a solution of dissolving 2 grams of sodium hydroxide in 2 ml of water, install the reactor, pour in stirring cooling water, turn on the stirring, turn on Heat up to 30°C, start feeding 11.5g of ethylene oxide (once every 5 minutes) for 30 minutes, after feeding, raise the temperature to 35°C, and react for 9 hours. After the reaction was finished, the reaction solution was poured into a 500 ml beaker, left to cool and precipitate, then suction filtered, and the liquid absolute ethanol was reclaimed for reuse next time, and the solid was recrystallized with 153 ml of toluene and heated to Dissolve at 85°C, stand still, gradually cool from 70°C to 10°C, precipitate crystals, and filter with suction; ...

Embodiment 2

[0033] Example 2 of the present invention provides a method for preparing bis-ether fluorene by catalyzing ethylene oxide, which is prepared according to the following steps:

[0034] Add 35 grams of bisphenol fluorene to a 500 ml pressure reactor, add 200 ml of isopropanol, add a solution of dissolving 1.5 grams of potassium hydroxide with 1.5 ml of water, install the reactor, pour in stirring cooling water, start stirring, and start Heat up to 30°C, start feeding 10.5 grams of ethylene oxide (once every 5 minutes), and the feeding time is 50 minutes. After feeding, the temperature is raised to 65°C, and the reaction is carried out for 6 hours. After the reaction is over, pour the reaction solution into a 500 ml beaker, let it stand to cool and precipitate, then suction filter, recover the liquid anhydrous ethanol for the next use, dry the solid and use 154 ml of toluene to recrystallize the solid 2 times, heated to 85°C to dissolve, left to cool to precipitate, suction filte...

Embodiment 3

[0036] Embodiment 3 of the present invention provides a method for preparing diether fluorene by catalyzing ethylene oxide, which is prepared according to the following steps:

[0037]Add 35 grams of bisphenol fluorene to a 500 ml pressure reactor, add 200 ml of absolute ethanol, add 50 ml of triethylamine, install the reactor, pour in stirring cooling water, start stirring, turn on heating, and raise the temperature to 30°C. Start to feed 10.5g of ethylene oxide (once every 10 minutes), and the feeding time is 60 minutes. After the feeding, the temperature is raised to 75° C., and the reaction is carried out for 9 hours. After the reaction is over, pour the reaction solution into a 500 ml beaker, let it cool and precipitate, then suction filter, reclaim the liquid anhydrous ethanol for the next use, recrystallize the solid with 150 ml of toluene, and heat Dissolve at 85°C, let it stand, gradually cool from 70°C to 10°C, precipitate crystals, and filter with suction; the mothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com