Polyurethane modified polycarboxylate superplasticizer and preparation method thereof

A technology of polyurethane modified high-efficiency water reducer, which is applied in the field of polyurethane modified polycarboxylic acid high-efficiency water reducer and its preparation, which can solve the problems of self-polymerization, insufficient steric hindrance and electrostatic repulsion, high polymerization temperature, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

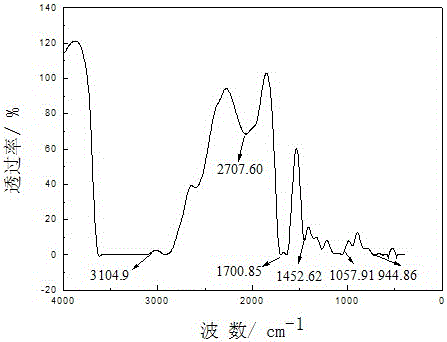

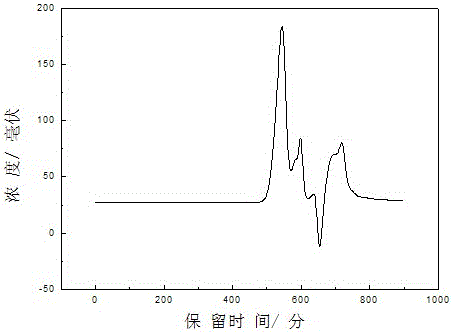

Image

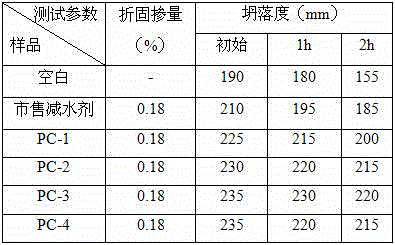

Examples

Embodiment 1

[0056] The preparation method of the raw material polyurethane prepolymer used in embodiment 1 is: 22.2g isophorone diisocyanate is placed in the there-necked flask, and the polyethylene glycol 1000 ( 25 g of polyethylene glycol 1000 containing 0.2 g of dibutyltin dilaurate and dimethylolpropionic acid in N-methylpyrrolidone solution (3.35 g of dimethylolpropionic acid dissolved in 5 mL of N-methylpyrrolidone), and then adding 50g of water, heated to 70°C and kept warm, then added dropwise the mixed solution of hydroxyl-terminated polysiloxane and 1,4-butanediol (9g of hydroxyl-terminated polysiloxane mixed with 3g of 1,4-butanediol into), 2.5g ethylenediamine and 1.5g sodium dodecylbenzene sulfonate, stir after the addition is complete, and when the mass percentage of free -NCO in the mixed solution is detected to be 16%, stop heating to obtain polyurethane prepolymerized body.

Embodiment 2

[0058] The preparation method of the raw material polyurethane prepolymer used in Example 2 is: 10g of isophorone diisocyanate is placed in a three-necked flask, and polyethylene glycol 1000 (20g A solution of 1 g of dibutyltin dilaurate) and dimethylolpropionic acid in N-methylpyrrolidone in polyethylene glycol 1000 (2.7 g of dimethylolpropionic acid dissolved in 5 mL of N-methylpyrrolidone), and 50 g water, heated to 75°C and kept warm, and then added dropwise the mixed solution of hydroxyl-terminated polysiloxane / 1,4-butanediol (mixing 5.7g of hydroxyl-terminated polysiloxane and 4g of 1,4-butanediol into), 1g of ethylenediamine and 2g of sodium dodecylbenzenesulfonate, stirred after the addition, and when the mass percentage of free -NCO in the mixture was detected to be 16%, stop heating to obtain a polyurethane prepolymer.

Embodiment 3

[0060] The preparation method of the raw material polyurethane prepolymer used in Example 3 is: 30g of isophorone diisocyanate is placed in a three-necked flask, and polyethylene glycol 1000 (20g A solution of 2 g of dibutyltin dilaurate) and dimethylolpropionic acid in N-methylpyrrolidone in polyethylene glycol 1000 (6.7 g of dimethylolpropionic acid dissolved in 8 mL of N-methylpyrrolidone), and 60 g water, heated to 70°C and kept warm, and then added dropwise to the mixed solution of hydroxyl-terminated polysiloxane / 1,4-butanediol (3g of hydroxyl-terminated polysiloxane mixed with 1.5g of 1,4-butanediol into), 1.3g ethylenediamine and 2.5g sodium dodecylbenzene sulfonate, stir after the addition is complete, and when the mass percentage of free -NCO in the mixed solution is detected to be 16%, stop heating to obtain polyurethane prepolymerized body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com