Three-proofing finishing agent for textile, as well as preparation method and application thereof

A three-proof finishing agent and fabric technology, applied in textiles and papermaking, fiber treatment, fibers repelling liquids, etc., can solve the problems of poor washing resistance and poor adsorption, and achieve good adhesion and durable water repellency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

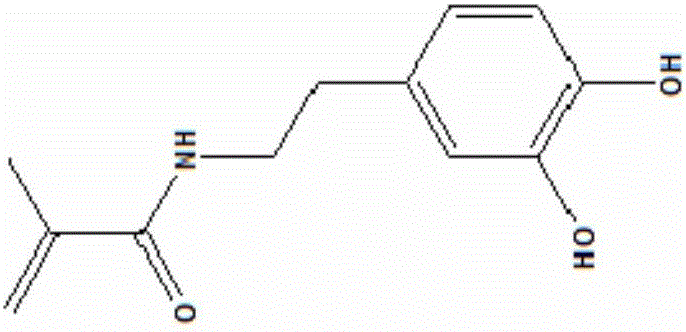

[0059] Will C 6 f 13 CH 2 CH 2 OC(O)-C(Cl)=CH 2 10g, 8g of stearyl methacrylate, 1g of glycidyl acrylate, 2g of dopamine methacrylamide, 10g of cationic silica hydrosol with an average particle diameter of 30nm and a mass content of 30%, dodecyl-3 -Mix 0.5g of methylammonium bromide, 1g of AEO-7, 33g of deionized water, and 15g of acetone, stir and emulsify at 40°C for 10 minutes, and then ultrasonically emulsify at this temperature for 5 minutes to obtain a monomer pre-emulsion.

[0060] Then put the monomer pre-emulsion in a 100ml four-necked flask equipped with a stirring paddle, a thermometer, a reflux tube, and a nitrogen device, add 0.3g of azobisisobutylamidine hydrochloride, replace the gas in the bottle with nitrogen, and stir The temperature was raised to 70° C. to initiate polymerization for 5 hours, and the temperature was maintained at 75° C. for 2 hours to obtain a translucent emulsion with bluish light. After cooling down to room temperature, the target pro...

Embodiment 2

[0062] Will C 4 f 9 SO 2 N(CH 3 )CH 2 CH 2 OC(O)-CH=CH 2 10g, 12g of cetyl methacrylate, 0.5g of hydroxyethyl acrylate, 1g of dopamine methacrylamide, 10g of cationic silica hydrosol with an average particle diameter of 30nm and a mass content of 30%, hexadecane Mix 0.6g of 3-methylammonium bromide, 0.6g of NP-40 with 36g of deionized water and 20g of ethylene glycol methyl ether, stir and emulsify at 40°C for 10 minutes, and then carry out ultrasonic emulsification at this temperature for 3 minutes. A monomer pre-emulsion is obtained.

[0063] Then the monomer pre-emulsion is placed in a 100ml four-necked flask with a stirring paddle, a thermometer, a reflux tube, and a nitrogen device, and 0.3g of azobisethylbutyronitrile is added to replace the gas in the bottle with nitrogen, and the temperature is raised to Initiate polymerization at 70°C for 4 hours, keep warm at 75°C for 3 hours to obtain a bluish translucent emulsion, and cool down to room temperature to obtain...

Embodiment 3

[0065] Will C 6 f 13 SO 2 N(C 2 h 5 )CH 2 CH 2 OC(O)-C(CH3)=CH 2 14g, stearyl methacrylate 10g, methylol acrylamide 0.5g, dopamine methacrylamide 0.5g, the average particle diameter is 30nm, and the mass content is 10g of cationic silica hydrosol of 25%, ten Mix 0.9g of octaalkyl-3-methylammonium chloride, 0.6g of NP-40 with 42.5g of deionized water and 18g of propylene glycol methyl ether, stir and emulsify at 40°C for 10 minutes, and then carry out ultrasonic emulsification at this temperature for 3 minutes , to obtain a monomer pre-emulsion.

[0066] Then the monomer pre-emulsion is placed in a 100ml four-necked flask with a stirring paddle, a thermometer, a reflux tube, and a nitrogen device, and 0.2 g of azobisethylheptanonitrile is added to replace the gas in the bottle with nitrogen, and the temperature is raised to Initiate polymerization at 70°C for 6 hours, keep warm at 75°C for 1 hour to obtain a bluish translucent emulsion, and cool down to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com