Preparation method for metal nanoparticle-loaded nitrogen-doped porous graphene

A technology of porous graphene and nanoparticles, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of unreported preparation methods, and achieve low cost, mild reaction conditions, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Feed according to the mass ratio of graphene oxide, metal precursor, hydrogen peroxide, and ammonia 1:0.033:0.05:30. Take 50mL of graphene oxide aqueous solution with a concentration of 6mg / mL, put it into a 100mL polytetrafluoroethylene reactor liner, add 5mL of hydrogen peroxide solution with a mass fraction of 0.3% and 30mL with a mass fraction of 28 - 30% aqueous ammonia solution and 10 mg potassium chloropalladate. The uniformly mixed reactants were put into a hydrothermal reaction kettle, and subjected to a hydrothermal reaction in an oven at 180° C. for 6 hours to obtain nitrogen-doped porous graphene loaded with palladium nanoparticles.

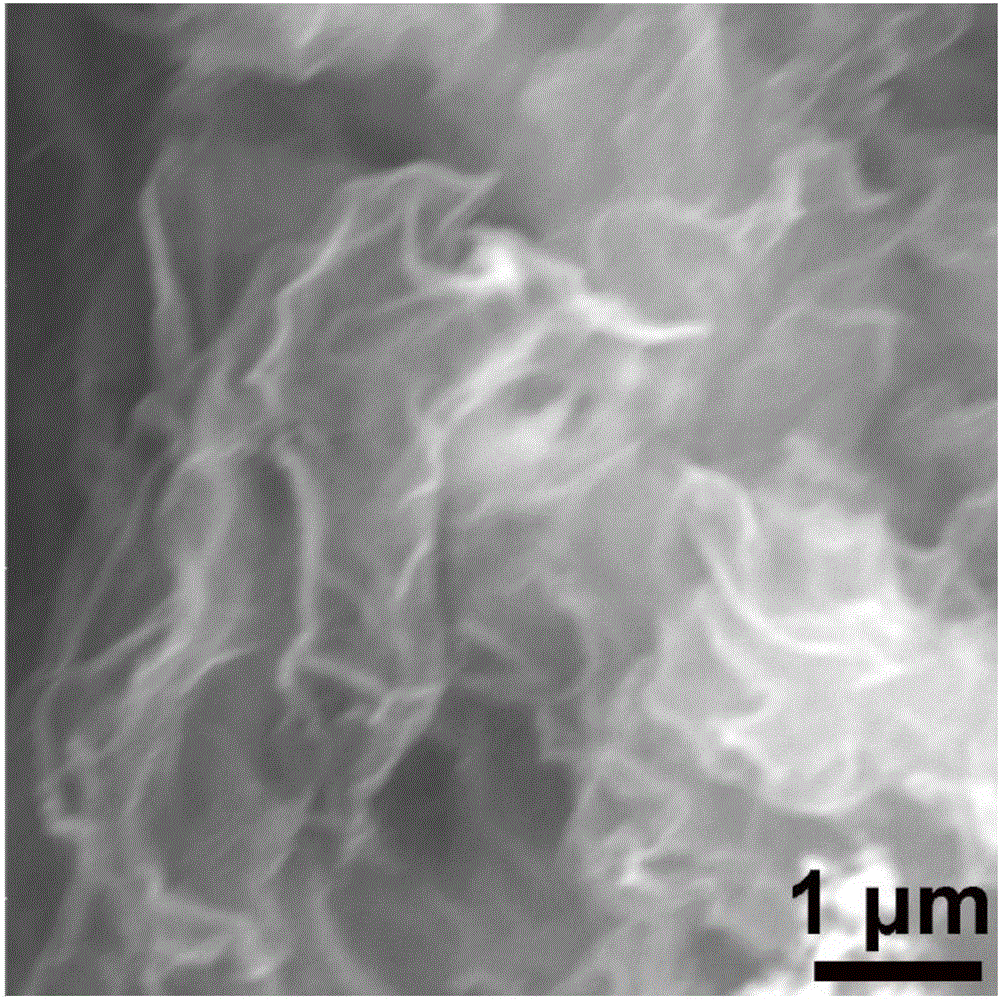

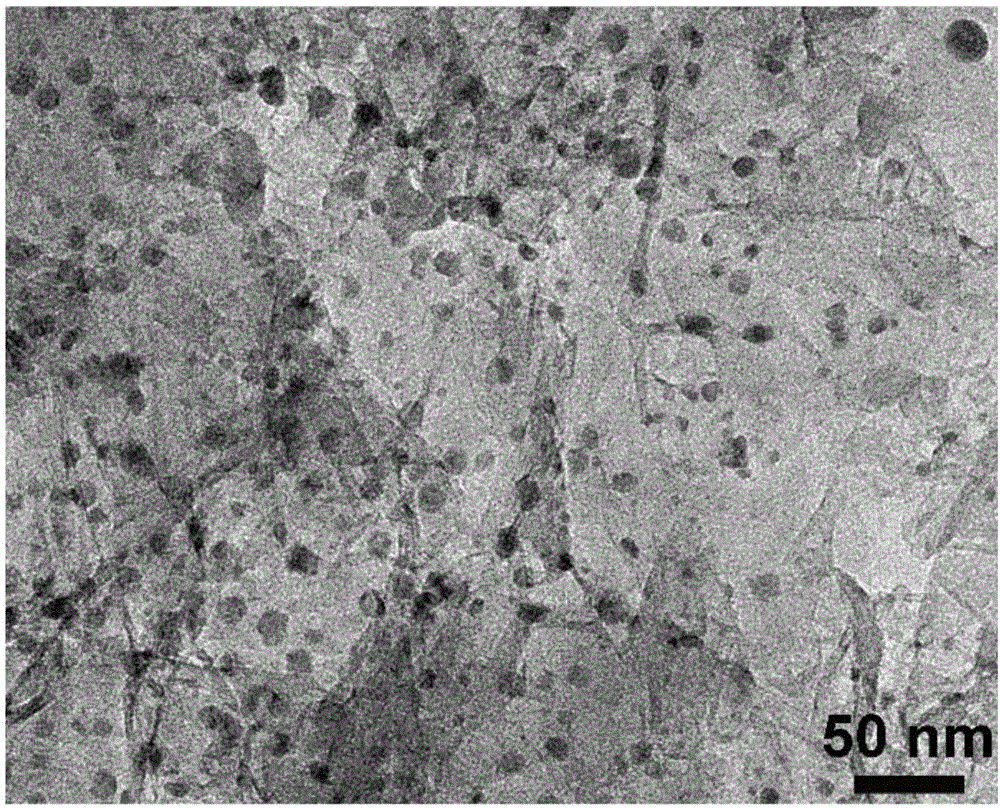

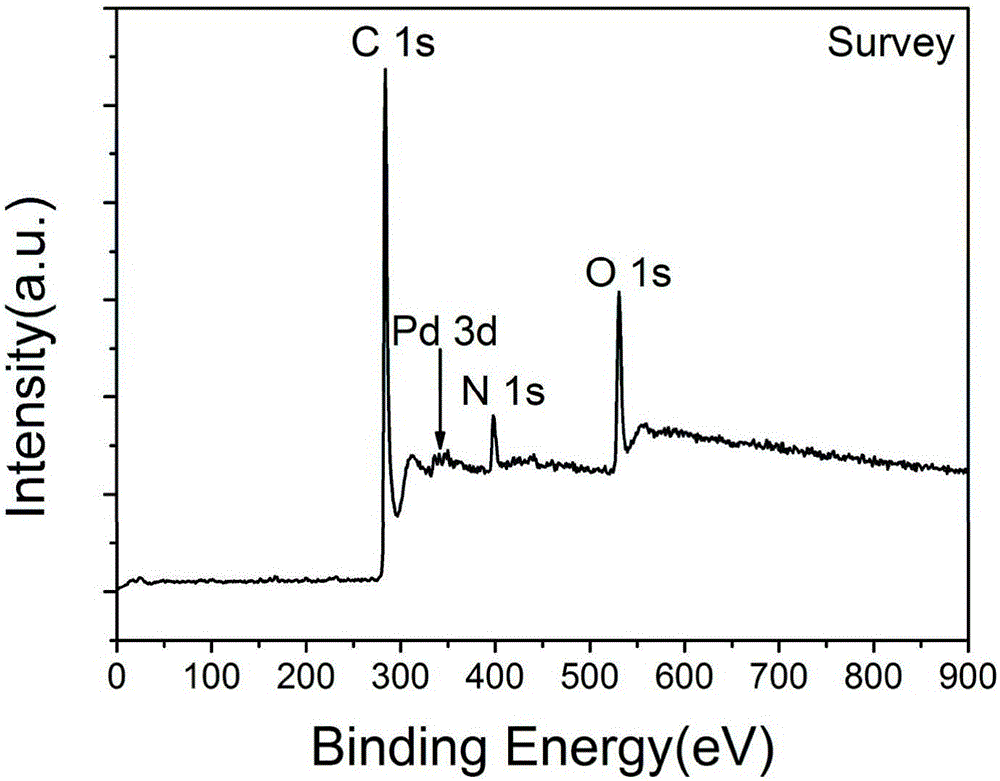

[0022] In order to better understand the structural characteristics and properties of the nitrogen-doped porous graphene loaded with palladium nanoparticles prepared in this example, SEM, TEM, XPS, adsorption-desorption and pore size distribution tests were carried out respectively.

[0023] like figure 1 Shown, the nitrogen-...

Embodiment 2

[0025] Feed according to the mass ratio of graphene oxide to metal precursor, hydrogen peroxide, and ammonia 1:0.001:0.05:0.05. Take 75 mL of graphene oxide aqueous solution with a concentration of 4 mg / mL, put it into a 100 mL polytetrafluoroethylene reactor liner, add 5 mL of hydrogen peroxide solution with a mass fraction of 0.3% and 0.05 mL of a hydrogen peroxide solution with a mass fraction of 28-30% under stirring conditions. % ammonia solution and 0.3mg potassium chloroplatinite. The uniformly mixed reactants were put into a hydrothermal reaction kettle, and hydrothermally reacted in an oven at 120° C. for 24 hours to obtain nitrogen-doped porous graphene loaded with platinum nanoparticles.

Embodiment 3

[0027] Feed according to the mass ratio of graphene oxide to metal precursor, hydrogen peroxide, and ammonia 1:0.008:0.05:24. Take 50mL graphene oxide aqueous solution with a concentration of 5mg / mL, put it into a 100mL polytetrafluoroethylene reactor liner, add 5mL hydrogen peroxide solution with a mass fraction of 0.3% and 20mL with a mass fraction of 28-30% Ammonia solution and 2mg potassium chloroaurate. The uniformly mixed reactants were put into a hydrothermal reaction kettle, and hydrothermally reacted in an oven at 180° C. for 10 hours to obtain nitrogen-doped porous graphene loaded with gold nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com