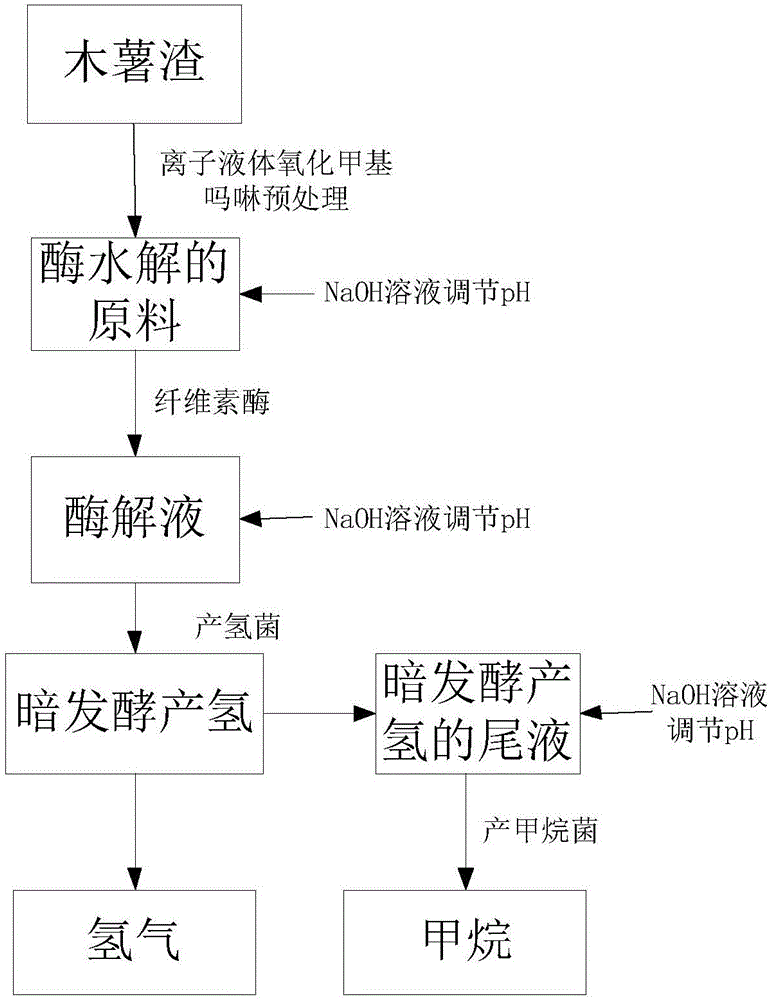

Method for preparing hydrogen and methane by adopting cassava dregs preprocessed by methyl morpholine oxide ionic liquid

A technology for oxidizing methyl morpholine and ionic liquid, which is applied in the chemical industry, climate sustainability, waste fuel, etc., can solve the problems of biomass fermentation that is not involved in hydrogen production, improve energy conversion efficiency, and improve enzymatic hydrolysis. Efficiency, the effect of improving the yield of hydrogen alkane gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Grind the cassava slag to a particle size of ≤0.02mm, place it in an oven and dry it at 6°C for 24 hours to obtain the pretreated raw material; mix 5g of the pretreated raw material with 50g of ionic liquid with a mass concentration of 85%, and put it into a sealed 50ml round bottom The flask was pretreated in an oil bath magnetic stirrer at 110°C for 2h. Then add 20ml of distilled water, continue to stir for 10min, then centrifuge at 6000r / min for 10min, collect the supernatant and recover the ionic liquid. The precipitate was washed 3 times with deionized water, placed in an oven at 60°C, and dried to constant weight, and used as raw material for enzymatic hydrolysis;

[0025] The raw material for enzymatic hydrolysis was placed in a 250ml Erlenmeyer flask, 100ml of deionized water was added, the pH of the solution was adjusted to 4.5 with NaOH with a mass concentration of 6mol / L, and cellulase was added in an amount of 5wt%. Then seal the Erlenmeyer flask, place it ...

Embodiment 2

[0030] Grind the cassava residue to a particle size of ≤0.02mm, place it in an oven and dry it at 6°C for 24 hours to obtain the pretreated raw material; mix the pretreated raw material (5g) with an ionic liquid (50g) with a mass concentration of 87% in a mass ratio of 1: 10 mixed, put into a sealed 50ml round bottom flask, and pretreated in an oil bath magnetic stirrer at 110°C for 2.5h. Then add 20ml of distilled water, continue to stir for 10min, then centrifuge at 6000r / min for 10min, collect the supernatant and recover the ionic liquid. The precipitate was washed 3 times with deionized water, placed in an oven at 60°C, and dried to constant weight, and used as raw material for enzymatic hydrolysis;

[0031] The raw material for enzymatic hydrolysis was placed in a 250ml Erlenmeyer flask, 100ml of deionized water was added, the pH of the solution was adjusted to 4.5 with NaOH with a mass concentration of 6mol / L, and cellulase was added in an amount of 5wt%. Then seal the ...

Embodiment 3

[0036] Grind the cassava residue to a particle size of ≤0.02mm, place it in an oven and dry it at 6°C for 24 hours to obtain the pretreated raw material; mix the pretreated raw material (5g) and the ionic liquid (50g) with a mass concentration of 90% at a mass ratio of 1: 10 mixed, put into a sealed 50ml round-bottomed flask, and pretreated in an oil bath magnetic stirrer at 110°C for 3h. Then add 20ml of distilled water, continue to stir for 10min, then centrifuge at 6000r / min for 10min, collect the supernatant and recover the ionic liquid. The precipitate was washed 3 times with deionized water, placed in an oven at 60°C, and dried to constant weight, and used as raw material for enzymatic hydrolysis;

[0037] The raw material for enzymatic hydrolysis was placed in a 250ml Erlenmeyer flask, 100ml of deionized water was added, the pH of the solution was adjusted to 4.5 with NaOH with a mass concentration of 6mol / L, and cellulase was added in an amount of 5wt%. Then seal the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com