A flexible self-supporting negative electrode material supported by carbon fiber lithium titanate nanosheets and its preparation method

A technology of negative electrode materials and negative active materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of increasing the cost of batteries, not having a good solution, and the cost of uniform loading of active materials remains high, achieving high battery ratio Effects of capacity and rate capability, good electrical conductivity, and ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

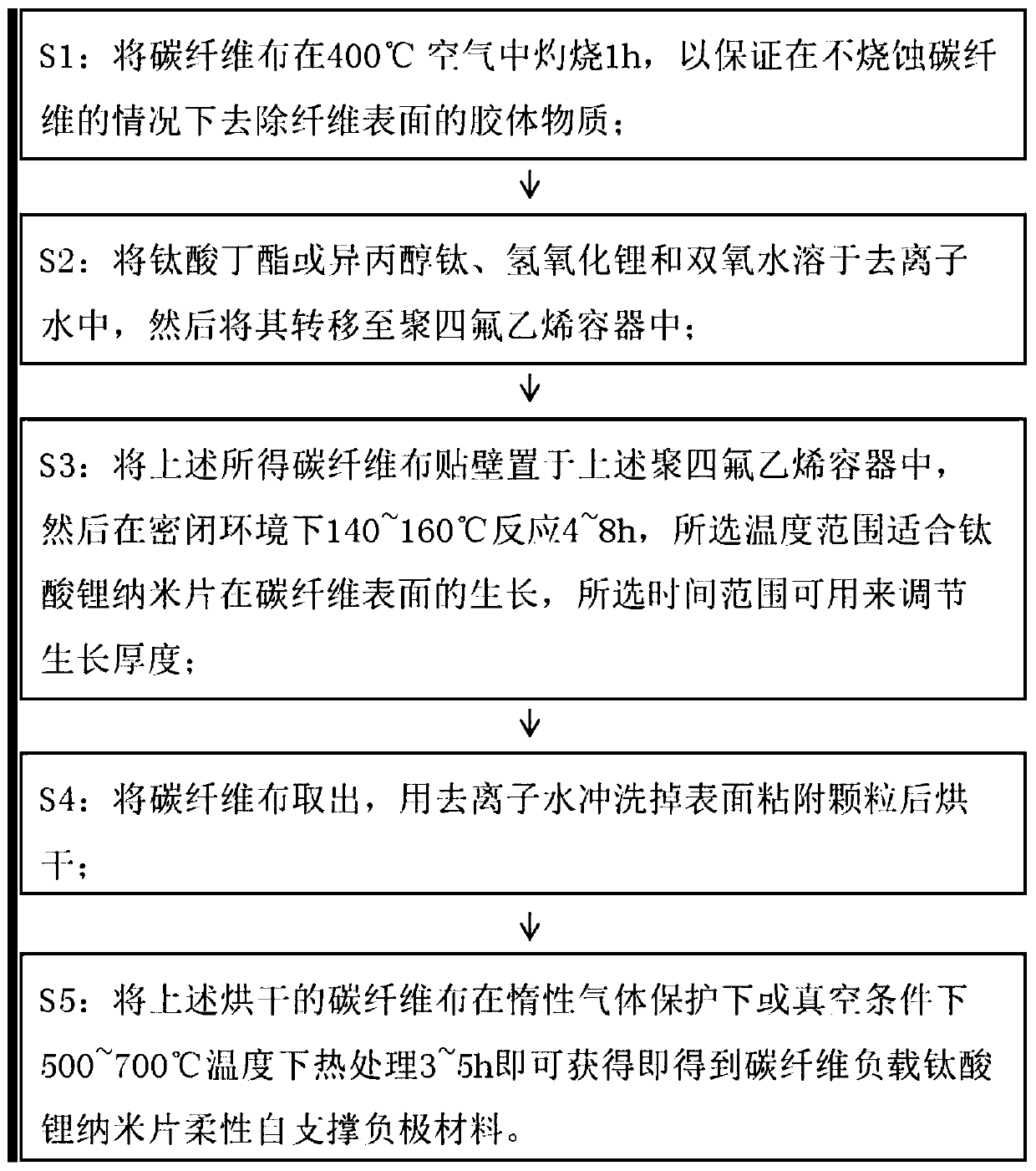

Method used

Image

Examples

Embodiment 1

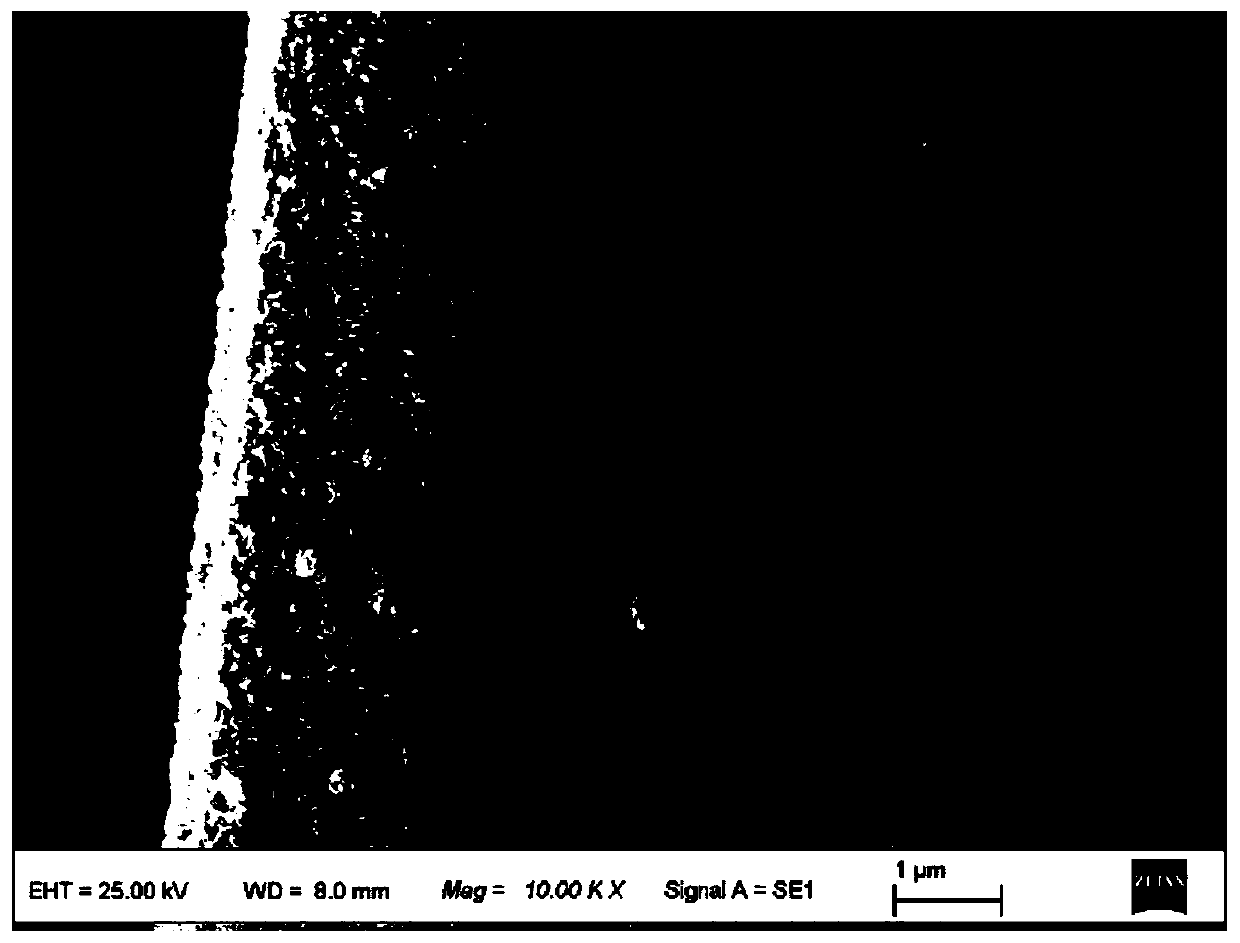

[0039] Burn the carbon fiber cloth (polyacrylonitrile-based carbon fiber non-woven fabric) in the air at 300°C (from room temperature to 300°C at a rate of 4°C / min) for 20 minutes to remove the colloidal substances on the surface for later use; Dissolve ester, lithium hydroxide and hydrogen peroxide in a molar ratio of 1:4:5 in an appropriate amount of deionized water (the amount of deionized water is 50ml of deionized water per 2ml of butyl titanate), and then transfer it to poly In a tetrafluoroethylene container; place the carbon fiber cloth on the wall in a polytetrafluoroethylene container, and then react in a closed environment at 140 ° C for 4 hours; take out the carbon fiber cloth, rinse off the surface adhesion particles with deionized water, and then dry it; The dried carbon fiber cloth was sintered at 500°C (from room temperature to this temperature at a heating rate of 2°C / min) under the protection of inert gas for 4 hours to obtain a flexible self-supporting negati...

Embodiment 2

[0042] Burn the carbon fiber cloth (pitch-based carbon fiber non-woven fabric) in the air at 360°C (from room temperature to 360°C at a rate of 4°C / min) for 20 minutes, and remove the colloidal substances on the surface for later use; butyl titanate, Lithium hydroxide and hydrogen peroxide are dissolved in an appropriate amount of deionized water (the amount of deionized water is 60ml of deionized water per 2ml of butyl titanate) in a molar ratio of 1:4.5:5, and then transferred to the polytetrafluoroethylene In an ethylene container; place the carbon fiber cloth on the wall in a polytetrafluoroethylene container, and then react in a closed environment at 160°C for 5 hours; take out the carbon fiber cloth, rinse off the surface adhesion particles with deionized water, and then dry it; The carbon fiber cloth was sintered at a temperature of 550°C (from room temperature to this temperature at a heating rate of 2°C / min) under the protection of an inert gas for 5 hours to obtain a ...

Embodiment 3

[0044] Burn the carbon fiber cloth (viscose-based carbon fiber non-woven fabric) at 400°C in air (from room temperature to 400°C at a rate of 4°C / min) for 20 minutes to remove the colloidal substances on the surface for later use; add butyl titanate , lithium hydroxide and hydrogen peroxide in a molar ratio of 1:5:5 were dissolved in an appropriate amount of deionized water (the amount of deionized water was 70ml of deionized water per 2ml of butyl titanate), and then transferred to poly In a vinyl fluoride container; place the carbon fiber cloth on the wall in a polytetrafluoroethylene container, and then react in a closed environment at 150°C for 6 hours; take out the carbon fiber cloth, rinse off the surface adhesion particles with deionized water, and then dry; The dry carbon fiber cloth was sintered at a temperature of 700°C (from room temperature to this temperature at a heating rate of 2°C / min) under the protection of an inert gas for 3 hours to obtain a flexible self-su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com