NASICON (Na Super Ion Conductors) structure-based sodium ion solid electrolyte composite material and preparation method and application thereof

A solid electrolyte and composite material technology, which is applied to a sodium ion solid electrolyte composite material based on a NASICON structure and its preparation and application fields, achieves the effects of simple preparation process, good safety performance and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is used to illustrate the sodium ion solid electrolyte composite material based on NASICON structure of the present invention, and its general formula is: xNa 3 La(PO 4 ) 2 / Na 3-2x Zr 2-x Si 2 P 1-2x o 12-8x , where 0

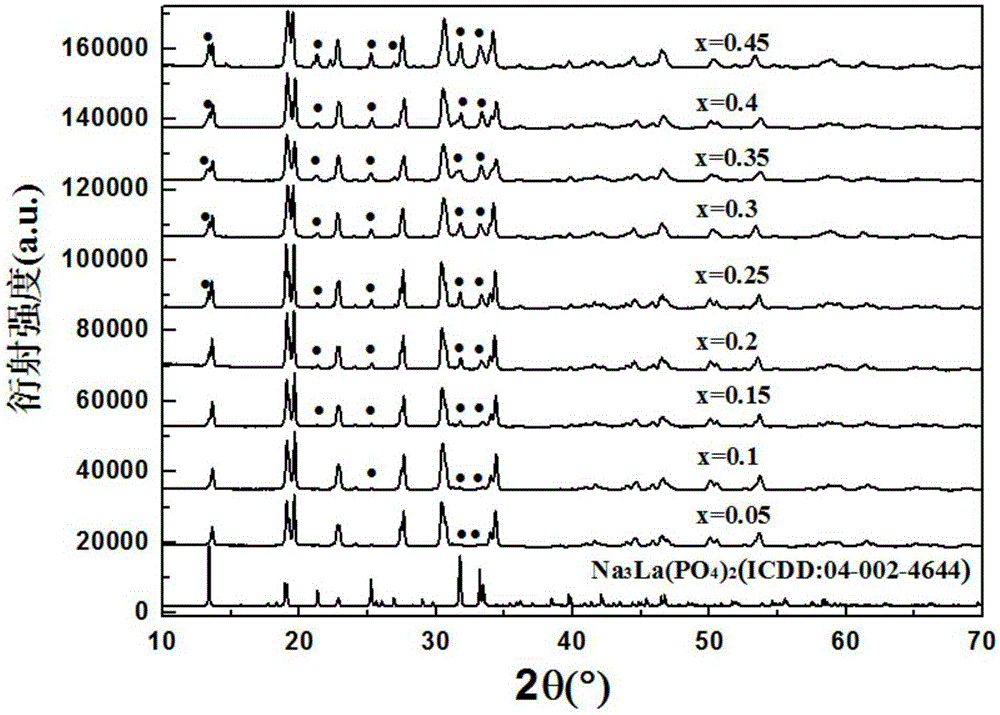

[0037] exist figure 1 The X-ray diffraction (X-ray diffraction, XRD) patterns of the sodium ion solid electrolyte composite materials with different composite ratios are given, wherein the diffraction peaks at the black solid circles correspond to Na 3 La(PO 4 ) 2 phase, other diffraction peaks correspond to NASICON phase.

[0038] The sodium ion solid electrolyte composite material can be applied to Na / S batteries, ZEBRA batteries, sodium ion all-solid-state batteries, sensors and the like.

[0039] The specific process of preparing the sodium ion solid electrolyte composite material based on the NASICON structure by using the solid-phase method described in the second aspect of the present invention and the sol-gel me...

Embodiment 2

[0041] This embodiment is used to illustrate the preparation of the sodium ion solid electrolyte composite material 0.05Na based on the NASICON structure by the solid-phase method described in the second aspect of the content of the present invention 3 La(PO 4 ) 2 / Na 2.9 Zr 1.95 Si 2 P 0.9 o 11.6 .

[0042] The required sodium stoichiometry 110wt% Na 2 CO 3 , ZrO 2 , La 2 o 3 (Heat treatment above 1000°C for 2 hours before use to remove adsorbed CO 2 ), SiO 2 , (NH 4 ) 2 HPO 4 Mix the ingredients in proportion to form a precursor; uniformly mix the precursor by ball milling to obtain a precursor powder; place the precursor powder in a muffle furnace and heat-treat it in an air atmosphere at 750°C for 12 hours; The pre-fired precursor powder was ground, pressed into tablets, and sintered at 1100° C. in an air atmosphere for 6 hours at a high temperature to obtain the ceramic sheet of the sodium ion solid electrolyte composite material.

[0043] Its powder X-ra...

Embodiment 3

[0046] In this embodiment, the sol-gel method described in the third aspect of the content of the present invention is used to prepare the sodium ion solid electrolyte composite material 0.15Na based on the NASICON structure 3 La(PO 4 ) 2 / Na 2.7 Zr 1.85 Si 2 P 0.7 o 10.8 .

[0047] Combine TEOS with H 2 O, ethanol is miscible with 1:10:20 molar ratio, adds citric acid (the molar ratio of citric acid and positive ion is 2:1), stirs and hydrolyzes 1h at 60 ℃, then adds the stoichiometric 115wt% of required sodium Sodium nitrate and stoichiometric zirconyl nitrate, lanthanum nitrate, and finally NH 4 h 2 PO 4 , heated up to 80°C and stirred to volatilize the water to obtain a gel precursor; put the gel precursor in an oven and bake at 200°C for 3 hours to obtain a xerogel; heat-treat the above xerogel at 550°C 5 hours; then sintering at 850°C for 12 hours; then grinding the pre-sintered precursor powder, and then sintering at 1200°C for 4 hours to obtain a sheet-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com