Preparation method of fresh zanthoxylum schinifolium oil

A technology of fresh green Chinese prickly ash and green prickly ash oil, which is applied in the direction of edible oil/fat, fat oil/fat production, and fat production, can solve the problems of difficult control of oil temperature, low efficiency, and little consumption, so as to avoid aroma and numbness. Loss of smell, improve work efficiency, avoid the effect of oxidation and blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

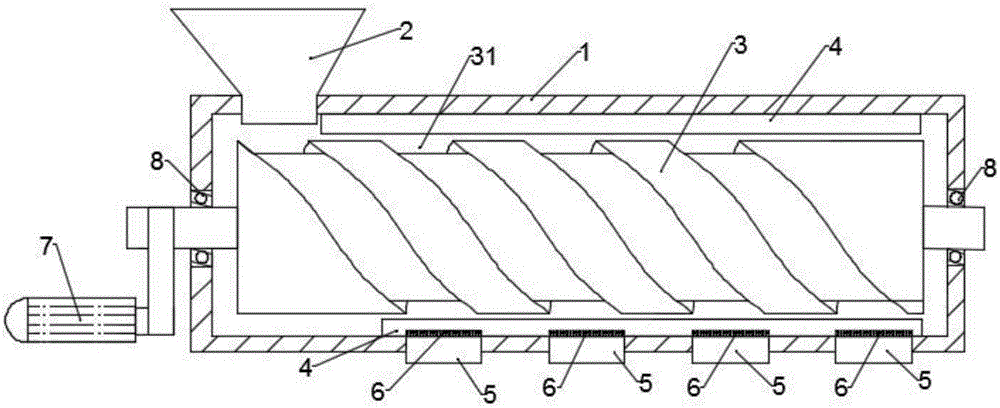

[0035] Such as figure 1 Shown, a kind of Chinese prickly ash peeling machine comprises a fuselage shell 1, an end on the upper part of the fuselage shell 1 is provided with a feed inlet 2, and a screw shaft 3 for conveying peppercorns is arranged in the said fuselage shell 1, A cutter 4 is arranged on the inner wall of the fuselage shell 1 , a peeling gap is formed between the cutter 4 and the screw shaft 3 , and a discharge port 5 is arranged at the bottom of the fuselage shell 1 . Wherein, the screw shaft 3 is arranged laterally in the fuselage shell 1, the inner wall of the fuselage shell 1 is cylindrical corresponding to the outer wall of the screw shaft 3, the cutter 4 is strip-shaped and The axial direction of the screw shaft 3 is fixed on the inner wall of the fuselage shell 1 . The Chinese prickly ash entering the fuselage shell 1 moves forward in the helical groove 31 of the helical shaft 3 along with the rotation of the helical shaft 3. During the movement, the pric...

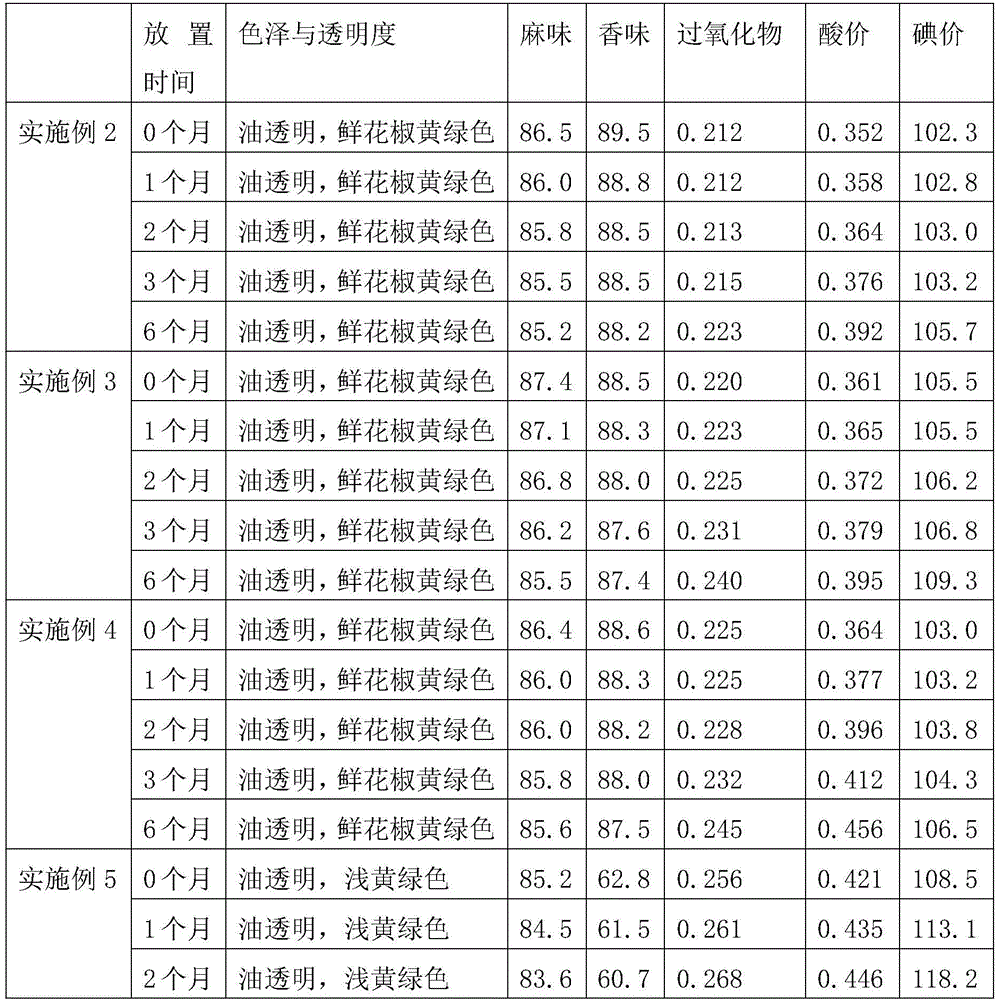

Embodiment 2

[0040] The preparation of green pepper oil adopts the following steps:

[0041] (1) Green pepper picking:

[0042] Use scissors to pick the mature green pepper bundles with branches and leaves to ensure the integrity of the oil cells, and store them at 5°C for 4 hours.

[0043] (2) Peeling and removing seeds by peeling machine:

[0044] Adopt the peeling machine of embodiment 1 to peel and remove the seeds of the fresh green Chinese prickly ash that step (1) plucks;

[0045] (3) Refining oil immersion:

[0046] After peeling and removing the seeds of the fresh green peppercorns, put them into a stabilizer solution with a mass concentration of 0.5% and soak them for 15 minutes, and crush the peeled peppercorns after soaking into a slurry with a peeler at 4000 rpm. Add 3 times (volume ratio) rapeseed oil to the slurry and mix, and stir for 2 hours to form a slurry mixture; the stabilizer is vitamin C, ascorbic acid and zinc gluconate in a mass ratio of 6:4:3 to form a mixture...

Embodiment 3

[0050] The preparation of green pepper oil adopts the following steps:

[0051] (1) Green pepper picking:

[0052] Use scissors to pick mature green pepper bundles with branches and leaves to ensure the integrity of the oil cells, and store them at 8°C for 2 hours.

[0053] (2) Peeling and removing seeds by peeling machine:

[0054] Adopt the peeling machine of embodiment 1 to peel and remove the seeds of the fresh green Chinese prickly ash that step (1) plucks;

[0055] (3) Refining oil immersion:

[0056] After peeling and removing the seeds of the fresh green peppercorns, put them into a stabilizer solution with a mass concentration of 0.1% and soak them for 20 minutes, and crush the peeled peppercorns after soaking into a slurry with a peeler at 5000 rpm. Add 1 times (volume ratio) soybean oil to the slurry, stir for 1 hour to form an oil slurry mixture; the stabilizer is vitamin C, ascorbic acid and zinc gluconate at a mass ratio of 5:3:2 to form a mixture.

[0057] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com