A kind of preparation method of marine biological protein peptide chelated copper

A marine organism and protein peptide technology, applied in animal feed, additional food elements, applications, etc., can solve the problems of low chelation rate of collagen peptide chelated copper products, low copper content of protein peptides, and unfavorable industrialization, etc. Achieve the effect of strong practicability, high chelated copper content and high copper chelation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Use a meat grinder to crush 1000kg of marine fish waste into fish paste, pump it into the enzymatic hydrolysis tank, turn on the stirring system, adjust the pH value of the fish paste to 8.0, turn on the heating system to raise the temperature, raise it to 50°C, stop heating and keep it warm, add 1kg Alkaline complex protease, enzymatic hydrolysis for 5h. After the enzymatic hydrolysis reaction, raise the temperature to 90°C, inactivate the enzyme for 30 minutes, centrifuge in a low-speed horizontal centrifuge for 30 minutes, and centrifuge in a high-speed disc centrifuge for 15 minutes, and filter to obtain the enzymatic protein peptide solution. Determine the solid content of the protein peptide solution to be 23%, adjust the pH of the protein peptide solution to 7.0, keep the temperature at 60°C, add 35kg of copper sulfate (pentahydrate), and perform chelation reaction for 3 hours. The reaction solution passes through the nanofiltration system, and then concentrated ...

Embodiment 2

[0026] Use a meat grinder to crush 5000kg of marine fish waste into fish paste, pump it into the enzymatic hydrolysis tank, turn on the stirring system, adjust the pH value of the fish paste to 8.5, turn on the heating system to raise the temperature, raise it to 45°C, stop heating and keep warm, add 5kg Alkaline complex protease, enzymatic hydrolysis for 7h. After the enzymatic hydrolysis reaction, the temperature was raised to 90°C, the enzyme was inactivated for 30 minutes, and the protein peptide solution was obtained by centrifugal filtration. Determine the solid content of the protein peptide solution to be 25%, adjust the pH of the protein peptide solution to 7.0, keep the temperature at 60°C, add 175kg of copper sulfate, and perform the chelation reaction for 3.5 hours. The reaction solution passes through the nanofiltration system, and then concentrated to 50% solids by three-effect concentration, and then spray-dried through the drying tower to obtain chelated copper...

Embodiment 3

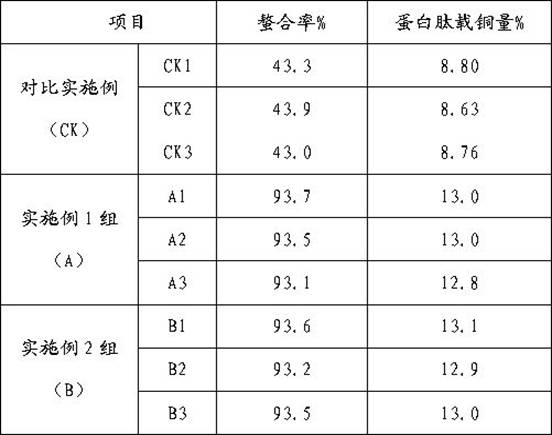

[0029] Example 3 Experimental research on the chelation rate of the protein peptide chelated copper product of the present invention and the amount of copper loaded on the protein peptide

[0030] 1. Test material

[0031] Comparative examples; Example 1 group; Example 2 groups.

[0032] experimental method

[0033] 2.1 Determination of chelation rate

[0034] (1) Determination of total copper content

[0035] Principle: After the sample is digested, EDTA can be complexed with copper ions under the condition of pH 5, and the copper content is calculated by indicating the titration end point with 1-(2-pyridylazo)-2-naphthol (PAN) indicator.

[0036] Reagents: nitric acid; hydrochloric acid; disodium edetate standard solution: c(EDTA-2Na)=0.02mol / L; 1-(2-pyridylazo)-2-naphthol (PAN) indicator: 0.2g Dissolve in 100ml 95% ethanol; ammonia water: 10% solution; acetic acid-sodium acetate buffer solution (pH=5): 82g sodium acetate plus 25ml acetic acid, dilute with water to 200ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com