Preparation method of Mg-doped lithium nickel cobalt aluminum oxide positive electrode material

A technology of nickel cobalt lithium aluminate and cathode material, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of complex process, lower real density, and poor precursor lattice order, and achieve material performance. Excellent, easy-to-react effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

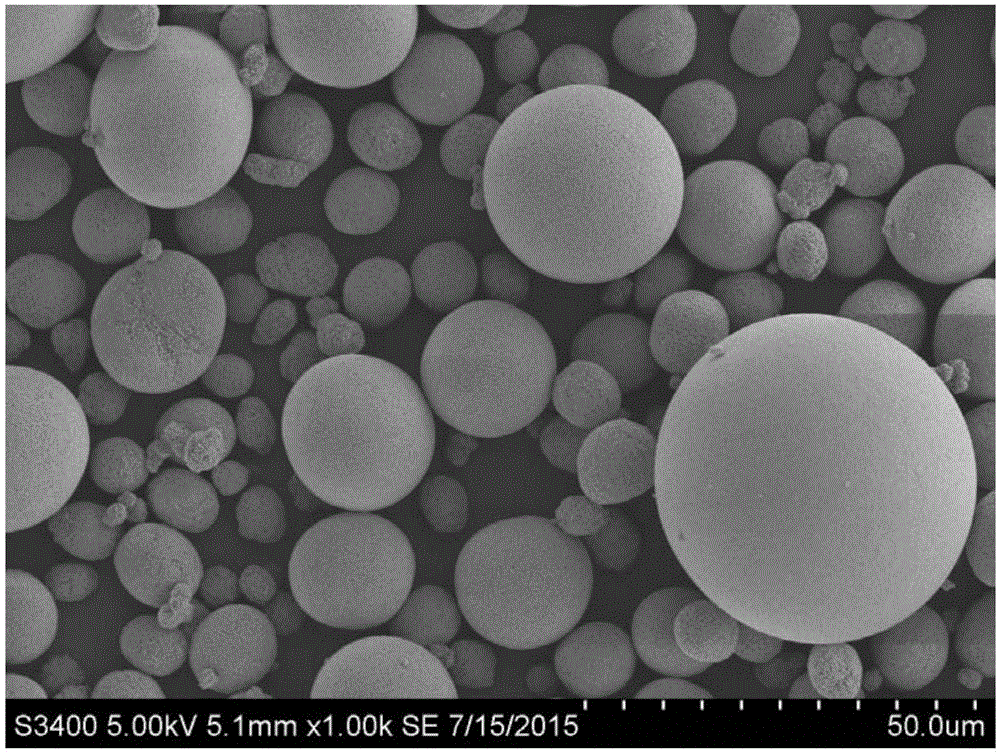

[0037] (1) Using nickel sulfate, cobalt sulfate, sodium metaaluminate, and magnesium acetate as raw materials, according to the molar ratio of Ni: Co: Al 0.92: 0.5: 0.03, the doping ratio of Mg is 0.3%, and the doping is prepared by coprecipitation method. The composite hydroxide precursor of the spherical nickel-cobalt-aluminum of Mg, the SEM picture of the composite hydroxide precursor is as follows figure 1 shown;

[0038] (2) Put the Mg-doped nickel-cobalt-aluminum composite hydroxide precursor in a resistance furnace, raise the temperature to 800°C at a rate of 5°C / min, keep it for 10 hours, and pre-oxidize in an oxygen atmosphere to obtain nickel-cobalt-aluminum Composite oxide Ni 1-x-y co x Al y o 2 , x=0.05, y=0.03;

[0039] (3) Mix the composite oxide of nickel-cobalt-aluminum and lithium hydroxide according to the ratio of atomic ratio nLi:(nNi+nCo+nAl)=1.20:1, use ethanol as the ball milling medium, ball mill for 10 hours evenly, dry and place After slowly hea...

Embodiment 2

[0042] (1) With nickel sulfate, cobalt sulfate, aluminum chloride, magnesium chloride as raw materials, according to Ni: Co: Al molar ratio 0.80: 0.15: 0.05, the doping ratio of Mg is 0.2%, prepare Mg-doped by co-precipitation method Composite hydroxide precursor of spherical nickel-cobalt-aluminum;

[0043] (2) Put the Mg-doped nickel-cobalt-aluminum composite hydroxide precursor in a resistance furnace, raise the temperature to 500°C at a rate of 3°C / min, keep it warm for 5 hours, and pre-oxidize in an oxygen atmosphere to obtain nickel-cobalt-aluminum The composite oxide Ni1-x-yCoxAlyO2, x=0.15, y=0.05;

[0044] (3) Mix the composite oxide of nickel-cobalt-aluminum and lithium hydroxide according to the ratio of atomic ratio nLi:(nNi+nCo+nAl)=1.11:1.0, use ethanol as ball milling medium, ball mill for 6 hours evenly, dry and place After slowly heating up to 650°C in an oxygen atmosphere in a resistance furnace, keep the temperature at a constant temperature for 15 hours, c...

Embodiment 3

[0047] (1) Using nickel sulfate, cobalt sulfate, aluminum sulfate and magnesium sulfate as raw materials, according to the Ni: Co: Al molar ratio of 0.73: 0.25: 0.02, the doping ratio of Mg is 0.02%, and prepare Mg doped by co-precipitation method Composite hydroxide precursor of spherical nickel-cobalt-aluminum;

[0048] (2) Put the Mg-doped nickel-cobalt-aluminum composite hydroxide precursor in a resistance furnace, raise the temperature to 300°C at a rate of 1°C / min, keep it for 1 hour, and pre-oxidize in an oxygen atmosphere to obtain nickel-cobalt-aluminum The composite oxide Ni1-x-yCoxAlyO2, x=0.25, y=0.02;

[0049] (3) Mix the composite oxide of nickel-cobalt-aluminum and lithium hydroxide according to the ratio of atomic ratio nLi:(nNi+nCo+nAl)=1.10:0.80, use ethanol as ball milling medium, ball mill for 3 hours evenly, dry and place After slowly raising the temperature to 500°C in an oxygen atmosphere in a resistance furnace, keep the temperature constant for 10 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com