Zeolite membrane, its production method, and separation method using the zeolite membrane

A separation method and zeolite membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of low processing capacity and long separation operation, and achieve excellent acid resistance, high separation performance and processing capacity. , the effect of suppressing the formation of pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

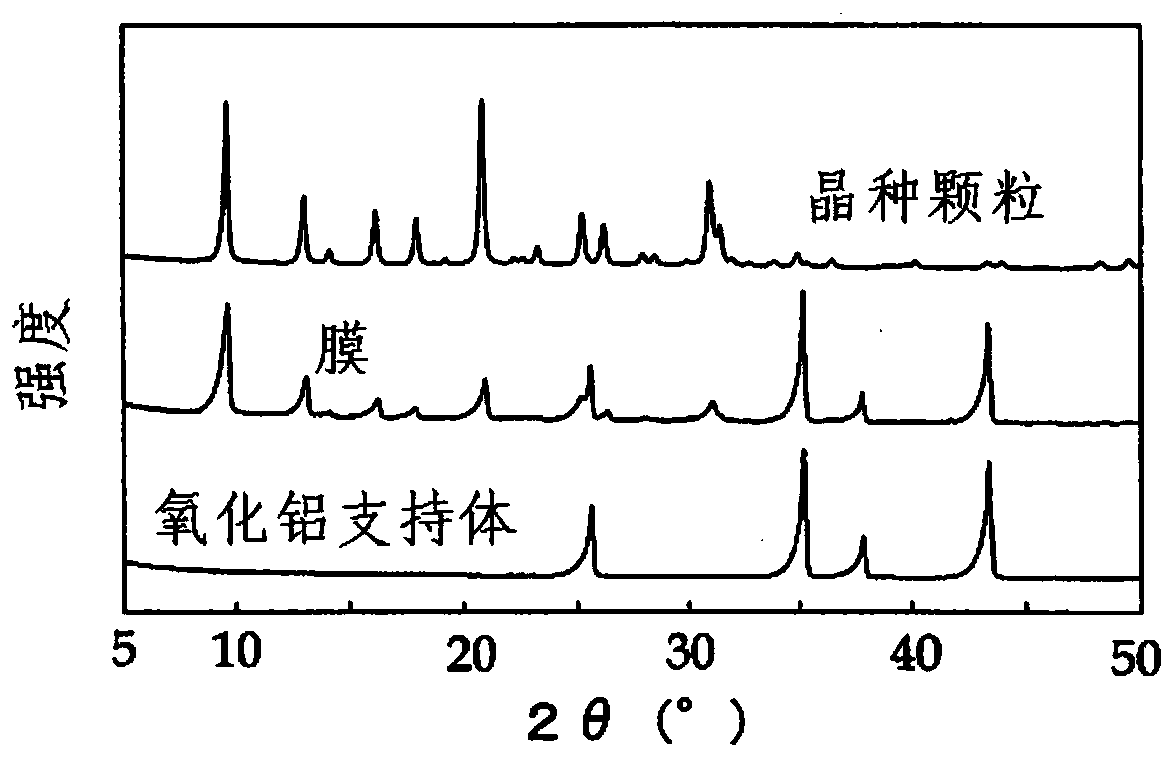

[0049] According to the preparation method of the present invention, for the zeolite membrane with the CHA type crystal structure formed into a film on the intermediate layer of the porous support with the intermediate layer, the Si / Al (molar ratio) of the CHA type zeolite particles is 9.5~100.5, preferably 10 to 100, more preferably 20 to 80, in the X-ray diffraction pattern obtained by irradiating the surface of the zeolite membrane with X-rays, the peak intensity near 2θ=18° is less than 0.5 times the peak intensity near 2θ=21°, Preferably less than 0.4 times, more preferably less than 0.35 times, most preferably less than 0.25 times, the peak intensity around 2θ=10° is less than 4 times of the peak intensity near 2θ=21°, preferably less than 3 times, more preferably less than 2.5 times, most preferably Preferably less than 0.2 times. The lower limit of (peak intensity around 2θ=18°) / (peak intensity around 2θ=21°) is not limited, and is usually 0.1. The lower limit of (pea...

Embodiment 1

[0065]

preparation example 1

[0068] A cylindrical alumina support (manufactured by Hitachi Zosen, 16 mm in diameter, 60 mm in length, and 10 μm in average pore diameter) with an intermediate layer (thickness about 50 μm, average pore diameter 0.8 μm) on the surface was prepared, and 25 g of / m 2 A CHA-type zeolite was attached as a seed crystal. The average pore diameter of the intermediate layer was measured in accordance with JIS K 3832.

[0069] Using FAU-type zeolite as raw material and N,N,N-trimethyl-1-adamantyl ammonium hydroxide (TMAdaOH) as an organic template, seed crystals were prepared in advance by the following method.

[0070] First, 8.09 g of TMAdaOH aqueous solution (manufactured by SACHEM, 25% by weight) was added to a 50 ml beaker, 0.38 g of sodium hydroxide was added, and the whole was stirred for 5 minutes. Thereafter, 2.1 g of HSZ-360 and 0.9 g of HSZ-390 (manufactured by TOSOH) were added as FAU-type zeolites, respectively, and stirred for 15 minutes. The molar composition of eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com