Natural fibroin protein fiber scaffold and preparation method

A silk fibroin and protein fiber technology, applied in medical science, prosthesis, etc., can solve the problems of complex electrospinning technology, unfavorable cell and tissue growth, and tissue growth restriction, etc., and achieves a favorable delivery of nutrients. , the effect of easy batch processing and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Natural mulberry silk was degummed by boiling with 0.05wt% sodium carbonate solution for 30 minutes, and obtained silk fibroin fiber after repeating 3 times;

[0031] (2) Disperse the silk fiber in step (1) in 88% formic acid solvent, the concentration of the silk fiber dispersion is 2%;

[0032] (3) Obtain sodium chloride particles with a diameter of 200-400 μm by sub-sieving, then add them into the silk fiber dispersion, the mass ratio of silk fibers to sodium chloride is 1:100, and stir evenly to obtain silk fiber- Sodium chloride-formic acid mixed solution;

[0033] (4) Pour the silk fiber-sodium chloride-formic acid into the mold, dry and remove the formic acid in the ventilated place, and obtain the silk fiber-sodium chloride solid;

[0034] (5) Immersing the silk fibroin fiber-sodium chloride solid in flowing water to remove the sodium chloride to obtain a wet silk fiber scaffold;

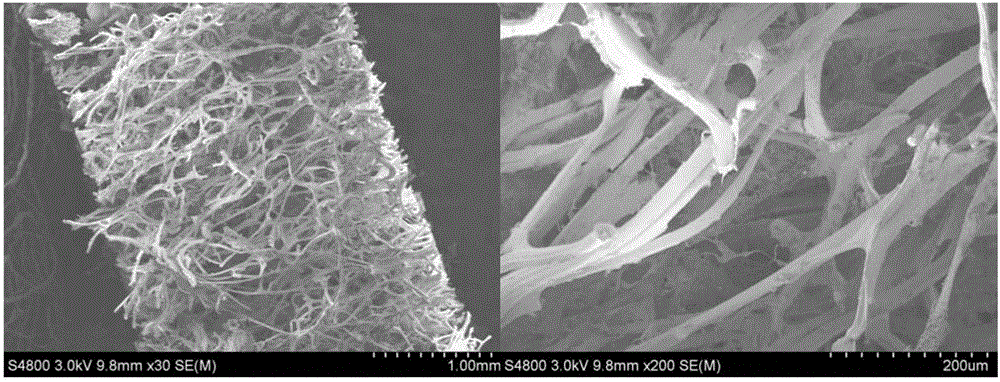

[0035] (6) The silk fibroin scaffold in wet state was frozen at -20°C, and ...

Embodiment 2

[0038] (1) Natural mulberry silk was degummed by boiling with 0.05wt% sodium carbonate solution for 30 minutes, and obtained pure silk fibroin fiber after repeating 3 times;

[0039] (2) Disperse the silk fiber in step (1) in 98% formic acid solvent, the concentration of the silk fiber dispersion is 2%;

[0040] (3) Obtain sodium chloride particles with a diameter of 200-400 μm by sub-sieving, then add them into the silk fiber dispersion, the mass ratio of silk fibers to sodium chloride is 1:100, and stir evenly to obtain silk fiber- Sodium chloride-formic acid mixed solution;

[0041] (4) Pour the silk fiber-sodium chloride-formic acid into the mold, then immerse in 75% ethanol to remove the sodium chloride, and obtain the wet silk fiber scaffold;

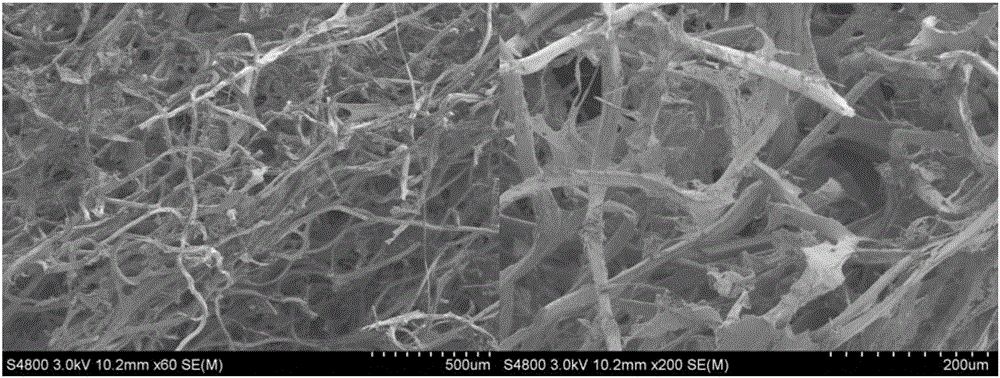

[0042] (6) The silk fibroblast scaffold in wet state was frozen at -10°C, and then freeze-dried at -20°C to obtain a natural silk fibrous scaffold.

[0043] attached figure 2 It is the scanning electron micrograph of the cross...

Embodiment 3

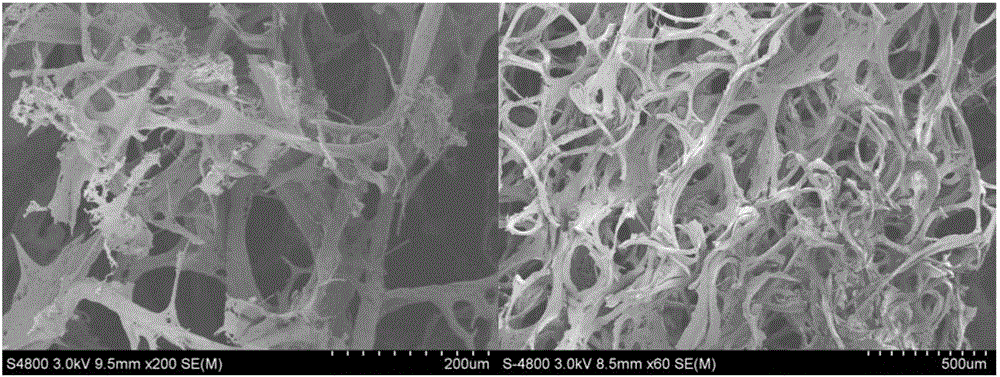

[0045] (1) Natural mulberry silk was degummed by boiling with 0.5wt% sodium carbonate solution for 30 minutes, and obtained pure silk fibroin fiber after repeating 3 times;

[0046] (2) Disperse the silk fiber of step (1) in 98% formic acid solvent, the concentration of silk fiber dispersion is 6%;

[0047] (3) Obtain sodium chloride particles with a diameter of 100-200 μm by sub-sieving, then add them into the silk fiber dispersion, the mass ratio of silk fibers to sodium chloride is 1:30, and stir evenly to obtain silk fiber- Sodium chloride-formic acid mixed solution;

[0048] (4) Pour the silk fiber-sodium chloride-formic acid into the mold, dry and remove the formic acid in the ventilated place, and obtain the silk fiber-sodium chloride solid;

[0049] (5) Immersing the silk fibroin fiber-sodium chloride solid in flowing water to remove the sodium chloride to obtain a wet silk fiber scaffold;

[0050](6) The silk fibroblast scaffold in wet state was frozen at -20°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com