Skin burn repair material and preparing method thereof

A technology for repairing materials and skin, applied in the field of biomedicine, can solve problems such as repairing materials that cannot meet clinical requirements, and achieve good biocompatibility, simple equipment and process, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

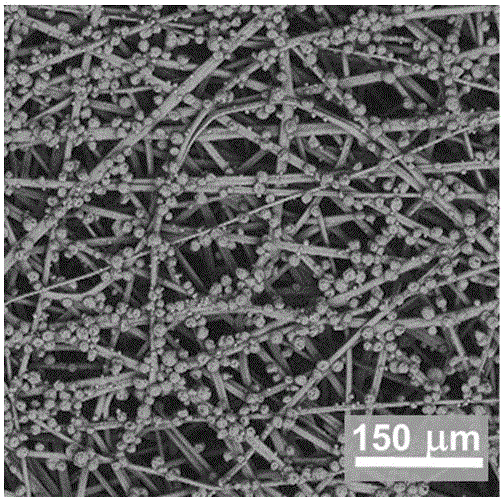

[0039]Blend polylactic acid and polyvinylpyrrolidone (mass ratio 7:1) into DCM and THF mixed solvent (mass ratio DCM / THF = 2:1) to prepare a blend solution with a mass fraction of 10%, and add Nano-silver (mass ratio is macromolecule / nanometer silver=200:1, said macromolecule includes polylactic acid and polyvinylpyrrolidone), mechanically stirred at 400 r / min for 6h, mixed evenly to form mixed spinning solution one; gelatin and dexamethasone (mass ratio: 300:1) were added to HFIP (hexafluoroisopropanol) to prepare a blend solution with a mass fraction of 9%, mechanically stirred at 300 r / min for 24 h, and mixed uniformly to form a mixed solution. Spinning Solution II. A coaxial electrospinning device was used to carry out coaxial electrospinning with the first spinning solution as the shell layer and the second spinning solution as the core layer. The relative humidity was 99%, the ambient temperature was 55°C, and the positive spinning voltage was 20 kV. , a flat-plate coll...

Embodiment 2

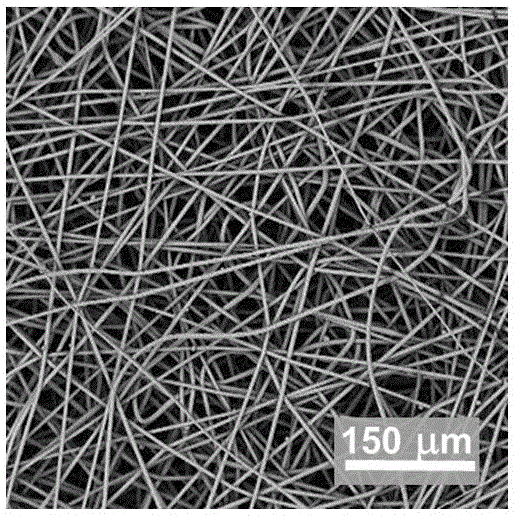

[0041] Polylactic acid and Panax notoginseng saponins hydrochloride (mass ratio: 10:1) were added to DMF to prepare a blend solution with a mass fraction of 35%, mechanically stirred at 100 r / min for 48 h, and mixed uniformly to form a blended solution. Spinning solution one. Polycaprolactone and polyethylene glycol (mass ratio: 5:1) were blended into THF to prepare a blend solution with a mass fraction of 10%, and fibroblast growth factor (FGF) (mass ratio: Polymer / FGF=1000:1, the polymer includes polylactic acid, polycaprolactone and polyethylene glycol), mechanically stirred at 800 r / min for 2 h, and mixed evenly to form mixed spinning solution 2. A coaxial electrospinning device was used to carry out coaxial electrospinning with spinning mixed solution 1 as the shell layer and spinning mixed solution 2 as the core layer. The relative humidity was 15%, the ambient temperature was 15°C, and the positive spinning voltage was 40 kV, using a flat-plate spinning device, a groun...

Embodiment 3

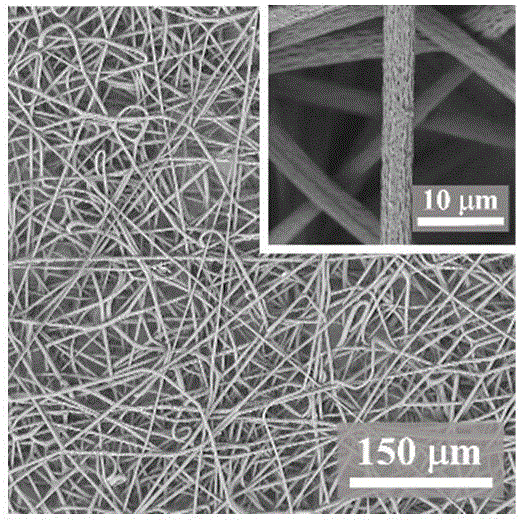

[0043] Collagen and chitosan (mass ratio 4:1) were blended into hexafluoroisopropanol to prepare a blend solution with a mass fraction of 11%, and the crude extract of Garcinia cambogia (mass ratio of high molecular weight / Garcinia cambogia crude extract=400:1, the macromolecules include collagen and chitosan), mechanically stirred at 350 r / min for 48 h, mixed evenly to form mixed spinning solution 1; polyethylene glycol was added to DMAC (N,N-dimethylacetamide) and CHCl 3 Mixed solvent (mass ratio DMAC / CHCl 3 = 1:4) to prepare a blend solution with a mass fraction of 8 %, mechanically stirred at a speed of 300 r / min for 18 h, and mixed evenly to form a mixed spinning solution II. A coaxial electrospinning device was used to carry out coaxial electrospinning with the first spinning solution as the shell layer and the second spinning solution as the core layer. The relative humidity was 80%, the ambient temperature was 35 °C, and the spinning voltage was 20 kV. A flat-plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com