Preparation method of polydopamine/polyacrylic acid supported nano-silver composite material

A technology of polydopamine and polyacrylic acid, which is applied in the field of preparation of silver nanocomposite materials, can solve the problems of uneven size and poor dispersion of nano silver particles, and achieve the effect of good control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of polydopamine / polyacrylic acid core-shell composite microspheres

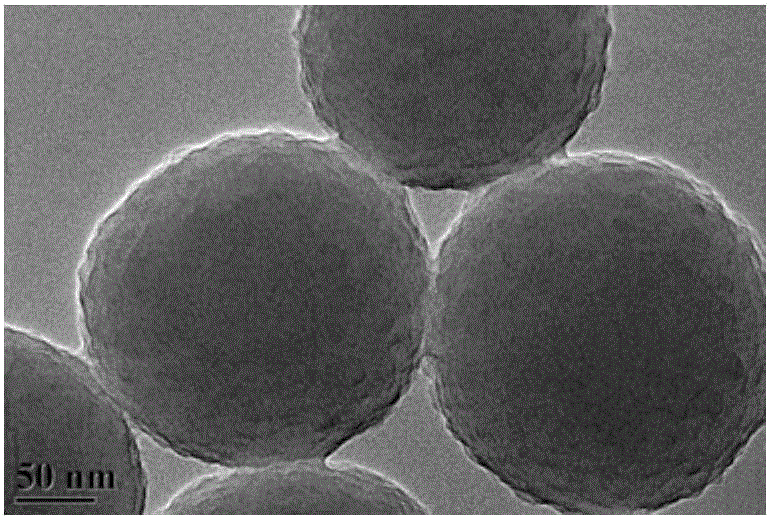

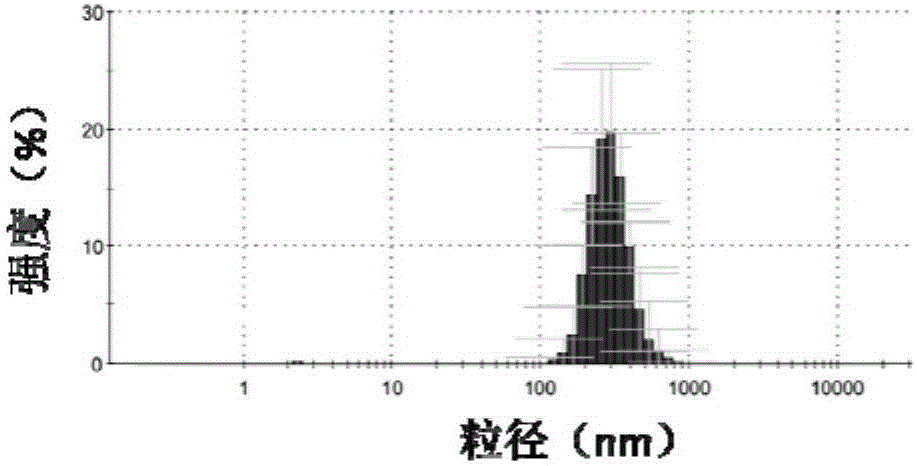

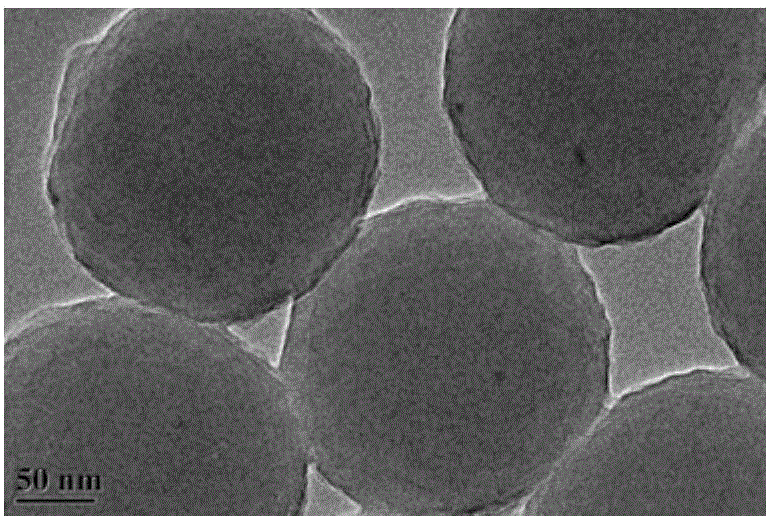

[0037]In a clean 50mL beaker, add 22.5mL double distilled water and 10mL absolute ethanol, then add 0.3mL concentrated ammonia water (mass fraction is 26% ~ 28%), after magnetic stirring (500 rpm) of the resulting mixture for 30 minutes, Slowly add 2 mL of dopamine aqueous solution with a mass-volume concentration of 50 mg / mL, react at room temperature for 30 hours, and centrifuge the resulting solution with twice-distilled water at 9500 rpm for 10 times, each time for 30 minutes, until the supernatant is colorless Finally, the lower precipitate was vacuum-dried at 80° C. to obtain polydopamine (PDA) microspheres. Depend on figure 1 It can be seen that the average particle diameter of the obtained PDA microspheres is 200nm; the hydration kinetic diameter (D h ) is about 236nm (see figure 2 ), narrow particle size distribution and good monodispersity.

[0038] Add 0.03g of polydopami...

Embodiment 2

[0043] In the step 2 of embodiment 1, the silver ammonia solution that initial concentration is 0.075mol / L is replaced with the silver ammonia solution that equal volume initial concentration is 0.005mol / L, other steps are identical with embodiment 1, obtain PDA / PAA- Ag composites. Depend on Figure 11 with 12 It can be seen that the loaded silver nanoparticles are more evenly dispersed and more uniform in size, and the particle size of the nano-silver is about 10-15 nm.

Embodiment 3

[0045] In the step 2 of embodiment 1, the silver ammonia solution that initial concentration is 0.075mol / L is replaced with the silver ammonia solution that equal volume initial concentration is 0.05mol / L, other steps are identical with embodiment 1, obtain PDA / PAA- Ag composites. Depend on Figure 13 with 14 It can be seen that the loaded silver nanoparticles are evenly dispersed and uniform in size, and the particle size of nano silver is about 20-25nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com