A kind of method that takes vermiculite as raw material to prepare PVC heat stabilizer

A heat stabilizer and vermiculite technology, applied in chemical instruments and methods, ultra-high pressure process, inorganic chemistry, etc., can solve problems such as uneven product quality, insufficient original product innovation, and restrictions on the development of heat stabilizers , to achieve the effect of small energy loss, obvious economic and social benefits, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

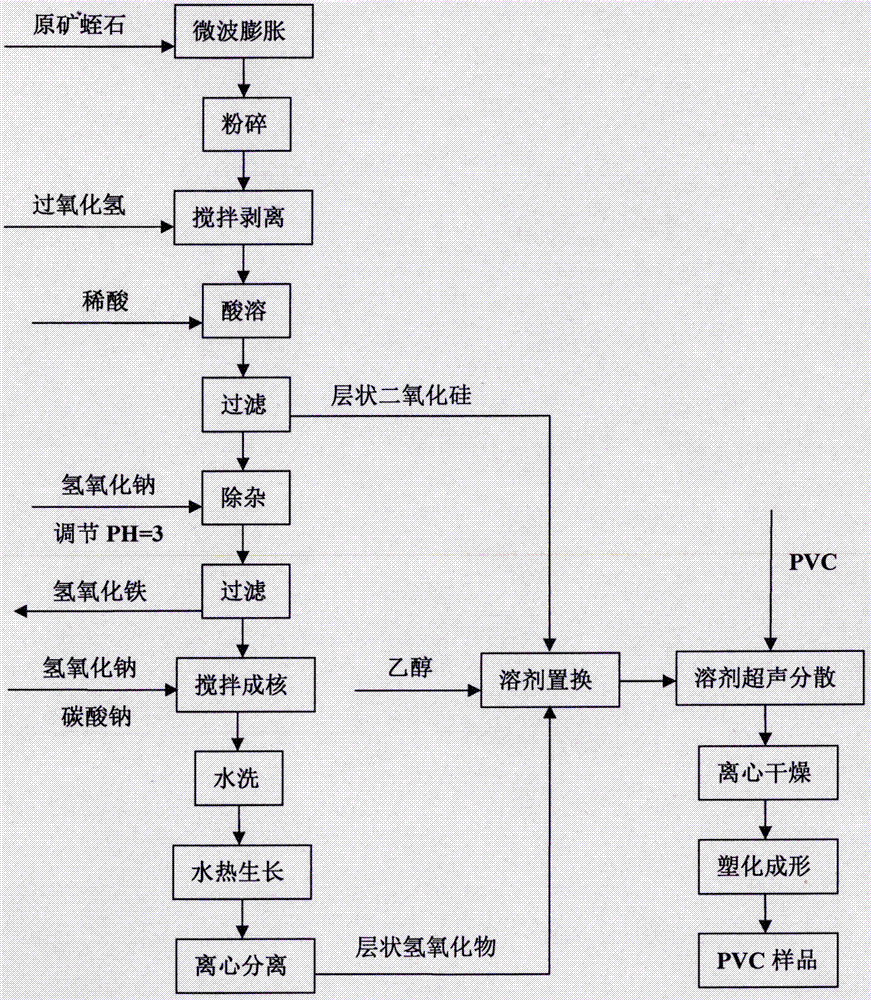

Method used

Image

Examples

Embodiment 1

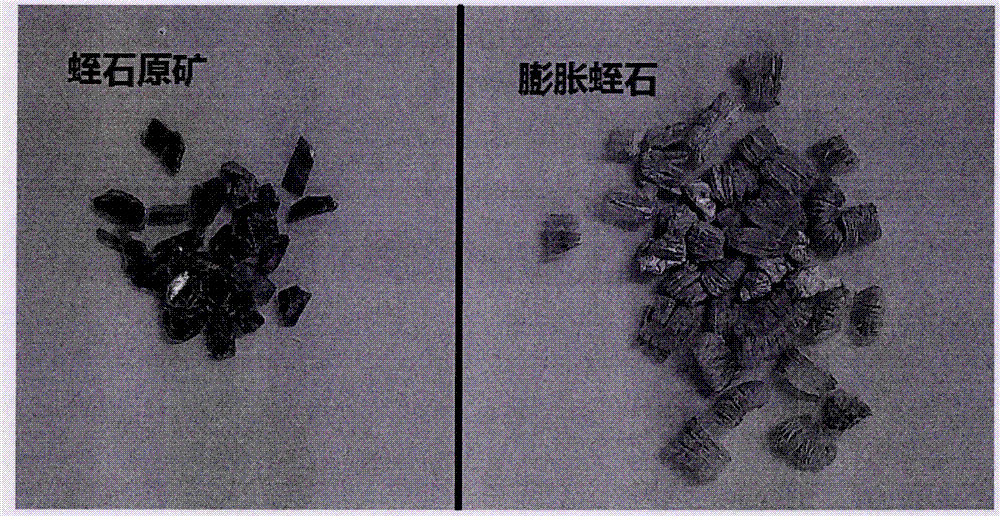

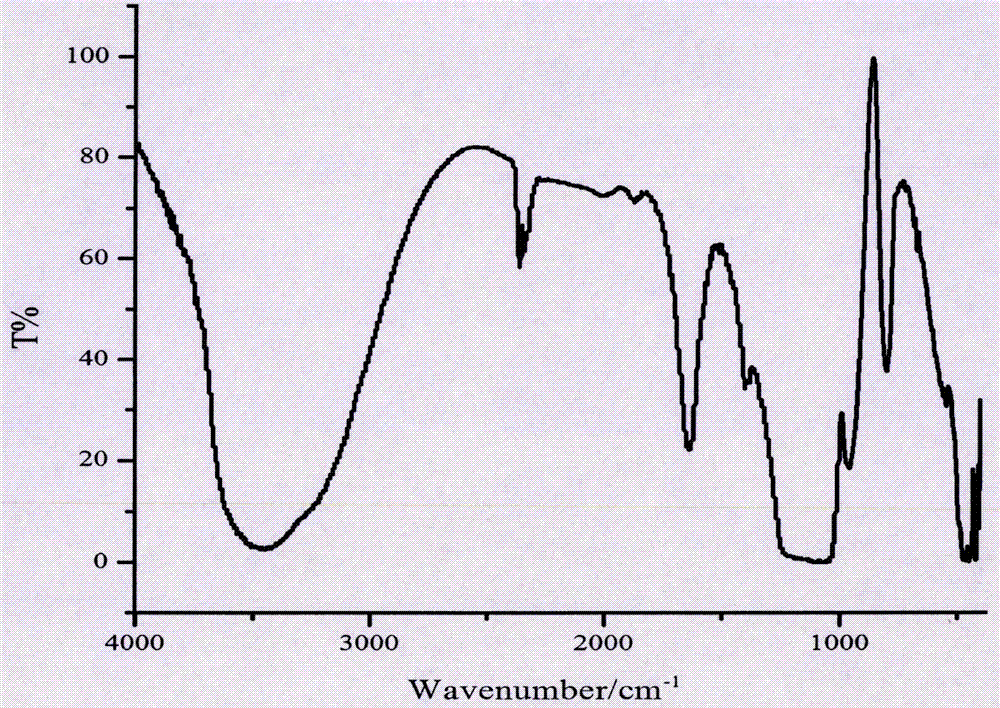

[0031] Take 5 grams of raw vermiculite, pulverize to 10 mesh, and expand under microwave power of 1500W for 60 seconds to obtain expanded vermiculite. The expanded vermiculite was pulverized to 120 mesh, put into a 30% hydrogen peroxide solution by weight, and stirred and peeled at 80 ° C. After stirring and peeling for 5 days, the pH value was adjusted to 1 by adding 0.1 mol / L hydrochloric acid, and then at 80 °C. Heating at ℃, after 3.5 hours of inversion, centrifugation to obtain supernatant liquid and solid, the solid after washing is silica heat stabilizer.

[0032] The supernatant obtained above was adjusted to pH 3 with 0.1mol / L sodium hydroxide solution, heated and flocculated at 80°C, filtered to remove the red solid ferric hydroxide to obtain a filtrate; in a beaker, put a mechanical Stir the slurry, adjust the stirring speed to 4000rpm, and gradually pour the 1:1 filtrate and sodium hydroxide and sodium carbonate mixed solution (mass concentration is 0.1mol / L sodium...

Embodiment 2

[0037] Take 5 grams of raw vermiculite, pulverize it to 20 mesh, and expand under microwave power of 1200W for 60 seconds to obtain expanded vermiculite. The expanded vermiculite was pulverized to 150 mesh, put into a 30% hydrogen peroxide solution by weight, and stirred and peeled at 80 °C. After stirring and peeling for 4 days, the pH value was adjusted to 1 by adding 0.1mol / L hydrochloric acid, and then the Heating at ℃, after 3 hours of inversion, centrifugation to obtain supernatant liquid and solid, and the solid is the silica heat stabilizer after washing.

[0038] The supernatant obtained above was adjusted to pH 3 with 0.1mol / L sodium hydroxide solution, heated and flocculated at 80°C, filtered to remove the red solid ferric hydroxide to obtain a filtrate; in a beaker, put a mechanical Stir the slurry, adjust the stirring speed to 3500rpm, and gradually pour the 1:1 filtrate and sodium hydroxide and sodium carbonate mixed solution (mass concentration is 0.1mol / L sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com