High-temperature cured type esterification modified cassava starch adhesive and preparation method thereof

A technology of tapioca starch and esterification modification, applied in starch-derived adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. problem, to achieve the effect of high initial viscosity, improved bonding strength and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

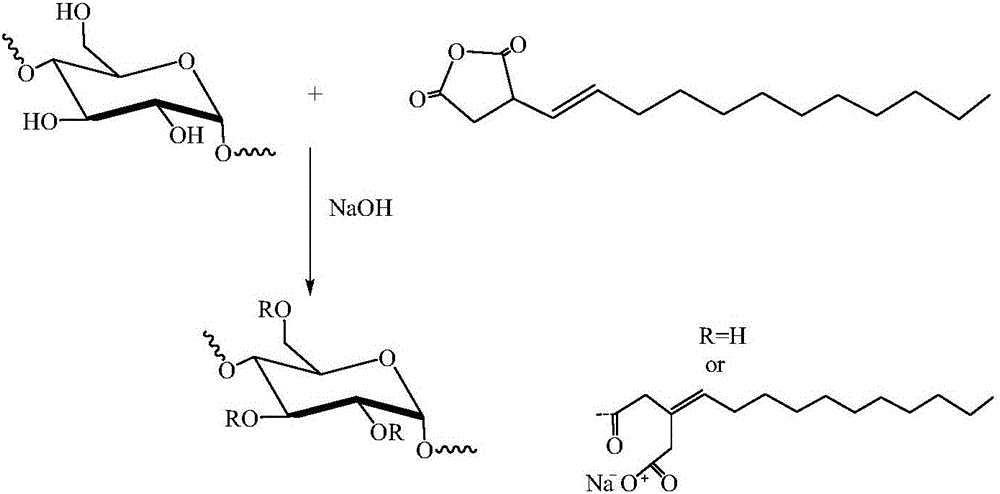

[0030] A high-temperature curing type esterified modified tapioca starch adhesive, the high-temperature curing type esterified modified tapioca starch adhesive is mainly composed of modified tapioca starch adhesive, isocyanate, antioxidant, flame retardant, light stabilizer, ultraviolet ray absorbent, its parts by weight are respectively 80 parts of modified tapioca adhesive, 8 parts of isocyanate, 0.5 part of antioxidant, 0.5 part of flame retardant, 0.02 part of light stabilizer, 0.5 part of ultraviolet light Absorbent, wherein the composition of the modified tapioca starch adhesive includes tapioca starch, polyvinyl alcohol, sodium lauryl sulfate, dodecenyl succinic anhydride.

[0031]The high-temperature curing type esterified modified tapioca starch adhesive described in this embodiment, the parts by weight of tapioca starch in the described modified tapioca starch adhesive is 100 parts by weight, the parts by weight of polyvinyl alcohol is 8 parts, lauryl The parts by we...

specific Embodiment approach 2

[0040] According to the preparation method of the high-temperature curing type esterification modified tapioca starch adhesive described in specific embodiment one, comprises the steps:

[0041] Step 1. Take 100 parts by weight of tapioca starch, add 156 parts by weight of distilled water to the weighed tapioca starch, and place it on a magnetic heating stirrer for heating and stirring at a heating temperature of 40°C. Stir The time is 10 minutes, the stirring speed is 200rad / min, and the tapioca starch emulsion is obtained, and the temperature is kept at 40° C. for use;

[0042] Step 2, take 8 parts by weight of polyvinyl alcohol and place it in a reactor with a stirrer, add 46 parts by weight of distilled water to the weighed polyvinyl alcohol, and stir Raise the temperature to 90°C, stir for 5 minutes, and stir at a speed of 200rad / min. After the polyvinyl alcohol is completely dissolved, cool down to 40°C and set aside;

[0043] Step 3. Add the tapioca starch emulsion pre...

specific Embodiment approach 3

[0048] A high-temperature curing type esterified modified tapioca starch adhesive, the high-temperature curing type esterified modified tapioca starch adhesive is mainly composed of modified tapioca starch adhesive, isocyanate, antioxidant, flame retardant, light stabilizer, ultraviolet ray absorbent, its parts by weight are respectively 100 parts of modified tapioca starch adhesive, 12 parts of isocyanate, 1.5 parts of antioxidant, 2 parts of flame retardant, 0.2 part of light stabilizer, 1 part of ultraviolet light Absorbent, wherein the composition of the modified tapioca starch adhesive includes tapioca starch, polyvinyl alcohol, sodium lauryl sulfate, dodecenyl succinic anhydride.

[0049] The high-temperature curing type esterified modified tapioca starch adhesive described in this embodiment, the parts by weight of tapioca starch in the described modified tapioca starch adhesive is 100 parts by weight, the parts by weight of polyvinyl alcohol is 8 parts, lauryl The part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com