A kind of lubricating oil composition of worm gear and its manufacturing method

A technology of lubricating oil composition and worm gear, applied in lubricating composition, petroleum industry, additives, etc., can solve problems such as damage to worm gear mechanism, shortening service life, insufficient attention to rust prevention performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

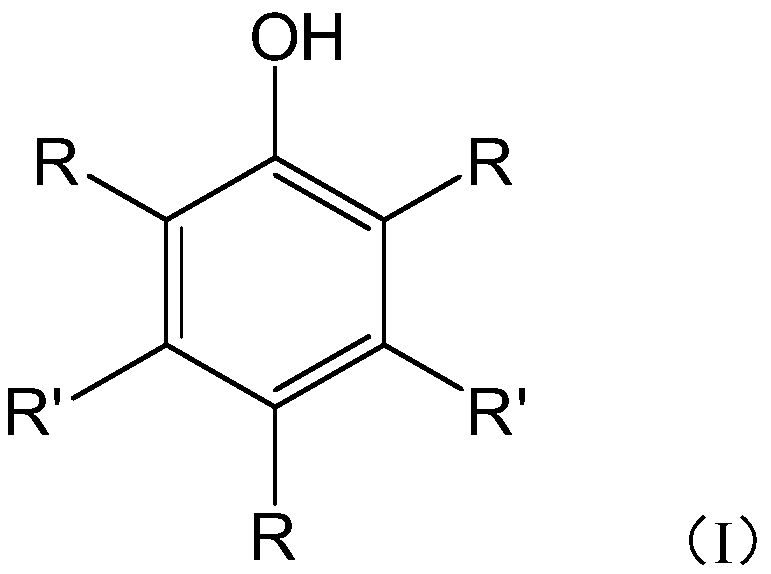

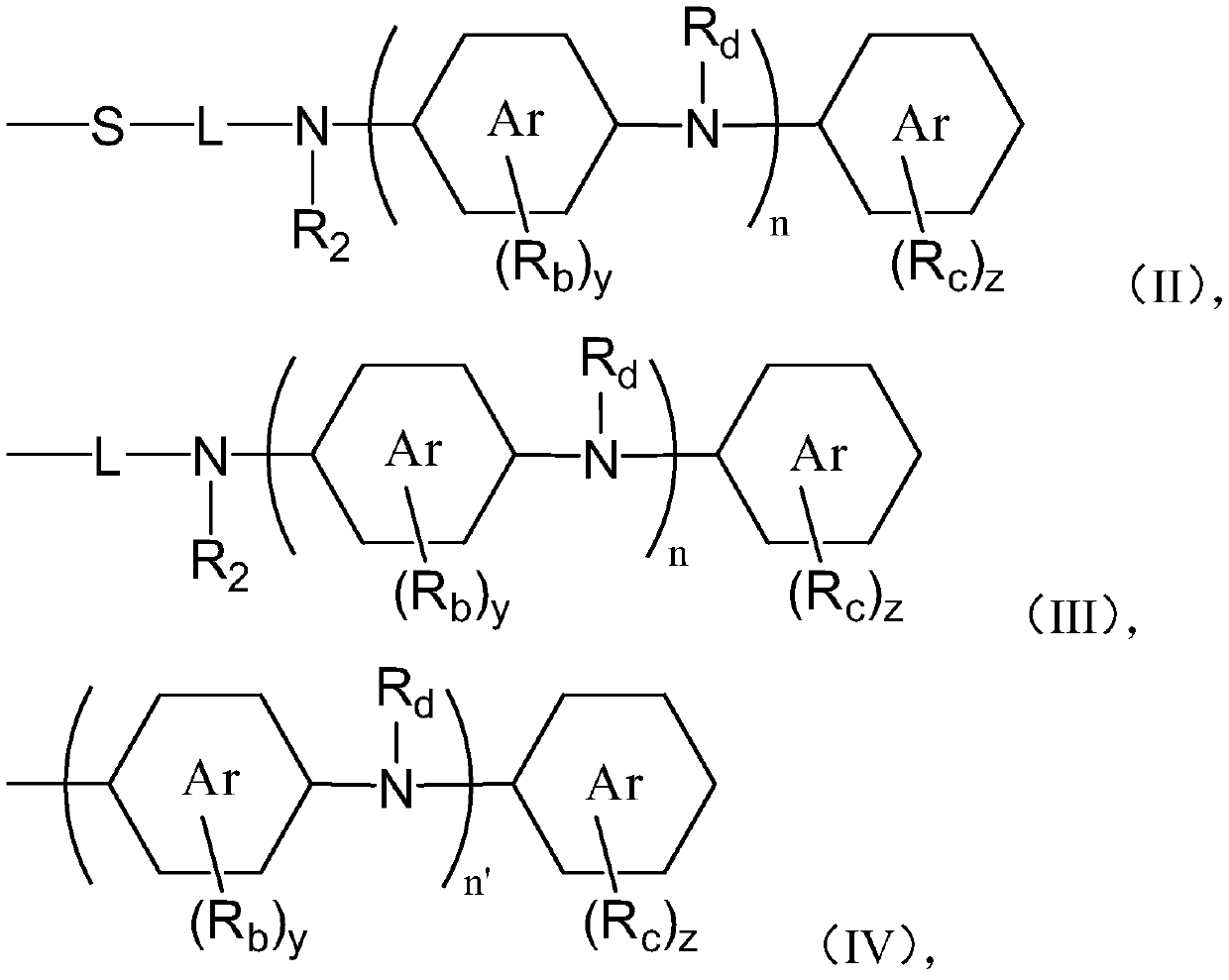

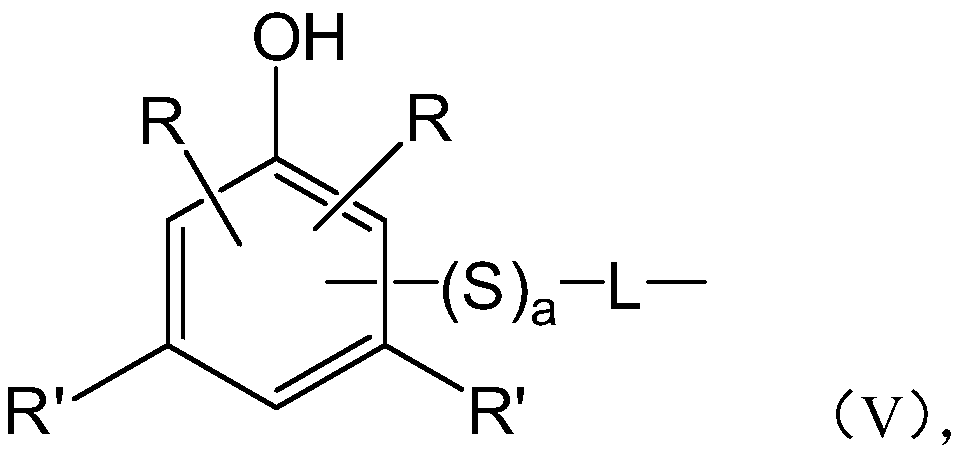

Method used

Image

Examples

Embodiment 1

[0241] In a 500mL four-neck flask equipped with a stirrer, thermometer, condenser and dropping funnel, add 58.79g (0.323mol) of 2-tert-butyl-6-mercaptophenol, 6.88g (0.048mol) of boron trifluoride Ethyl ether (catalyst for alkylation reaction), 100 mL of n-hexane solvent and 161.61 g (0.162 mol) of polyisobutene (Mn=1000, manufactured by Jihua Group Fine Chemicals Co., Ltd.) were reacted at 80° C. for 2 h. After the reaction, the reaction mixture was washed once with 5% potassium hydroxide solution by mass fraction, and washed to neutrality with hot water to remove the catalyst, and then the solvent and unreacted phenol were distilled off under reduced pressure to obtain polyisobutylene mercaptophenol, hydroxyl The value was 53.49 mgKOH / g. For the determination of hydroxyl value, refer to the acetic anhydride method in GB / T7383-2007.

[0242] An example reaction is as follows:

[0243]

[0244] From the proton nuclear magnetic spectrum analysis of the polyisobutylene merc...

Embodiment 2

[0246]

[0247] Under a nitrogen protection atmosphere, in a 250mL four-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel, add 30.58 grams (156 mmol) of 2-mercapto-4-methyl-6-methylphenol, 9.29 grams ( 112mmol) formaldehyde, 32.38g (176mmol) N-phenyl-p-phenylenediamine and 100mL toluene, stirred rapidly, and reacted at 100°C for 2h. After the reaction was finished, the solvent and a small amount of water generated were distilled off under reduced pressure, and the shielded phenol product with the structure shown in the title was obtained through column chromatography separation.

[0248] Product characterization data are as follows:

[0249] 1 H NMR (300MHz, CDCl 3 ): δ1.40(9H), 2.37(3H), 4.02(1H), 4.83(2H), 6.95-7.00(12H), 7.26(2H), 7.55(1H);

[0250] 13 C NMR (75MHz, CDCl 3 ): δ21.2, 30.1, 34.1, 49.9, 114.3, 118.9, 119.4, 121.8, 122.2, 125.8, 126.5, 129.5, 131.8, 132.3, 133.5, 143.3, 150.8;

[0251] C 24 h 28 N 2 OS calcd for ...

Embodiment 3

[0253]

[0254]Under a nitrogen protective atmosphere, in a 250mL four-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel, add 31.65 grams (133mmol) of 2,6-di-tert-butyl-4-mercaptophenol, 1.86 grams (62mmol ) formaldehyde, 28.15 grams (153 mmol) of N-phenyl-p-phenylenediamine, 0.75 grams (7.5 mmol) of hydrochloric acid and 150 mL of isopropanol, stirred rapidly, and reacted at 25 ° C for 24 h. After the reaction was finished, the solvent and a small amount of water generated were distilled off under reduced pressure, and the shielded phenol product with the structure shown in the title was obtained through column chromatography separation.

[0255] Product characterization data are as follows:

[0256] 1 H NMR (300MHz, CDCl 3 ): δ1.36-1.54(18H), 3.75(1H), 4.80(2H), 5.32(1H), 6.80(2H), 6.97(5H), 7.17(2H), 7.26(2H), 7.55(1H) ;

[0257] 13 C NMR (75MHz, CDCl 3 ): δ29.6, 34.6, 51.2, 119.4, 121.8, 126.5, 129.5, 131.4, 136.6, 144.5, 153.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com