Catalyst components for olefin polymerization and their preparation and use

A technology of olefin polymerization and catalyst, which is applied in the field of preparation of catalyst components, can solve the problems of unsuitable materials, narrow molecular weight distribution of polyolefins, etc., and achieve the effect of good shape, wide molecular weight distribution and good orientation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

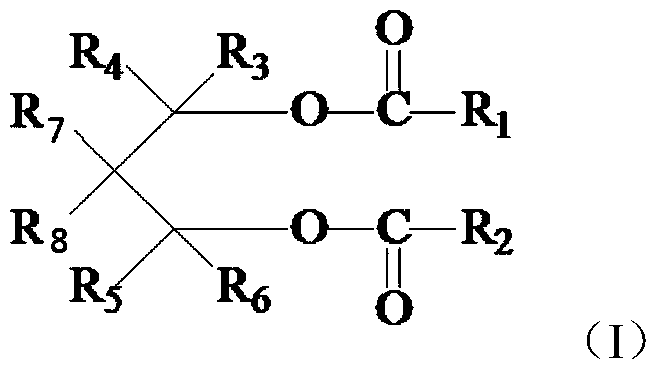

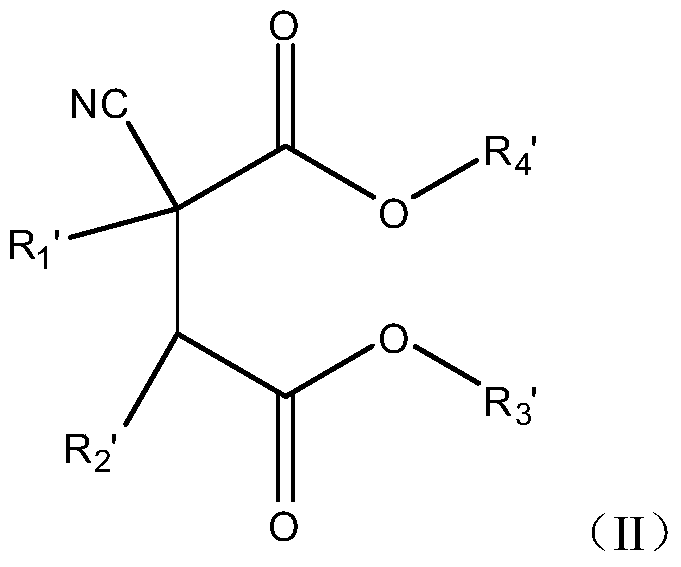

Method used

Image

Examples

preparation example 1

[0121] Preparation of diethyl 2-cyano-2,3-diisopropylsuccinate: In a 1000 mL round bottom flask, add 48.1 g of sodium tert-butoxide and 300 mL of DMF. Heat to reflux. While stirring, 81.5 g of ethyl cyanoisovalerate were added dropwise. Heat up to 80°C and reflux for 2 hours. A mixed solution of 99.6 g of ethyl bromoisovalerate and 100 mL of DMF was added dropwise. Continue to heat up to 100°C for 20 hours. Stop the reaction, cool and filter. Filter cake washing. The filtrate was rotovapped to remove solvent. Add saturated ammonium chloride solution for washing and separate the layers. The organic phase was dried, filtered and spin-dried of solvent. Get crude products. Vacuum distillation yielded 94.2 g of the product (8 mbar, 123-127° C.). 1 H-NMR (CDCl 3 / TMS,300MHz)(δppm):0.99-1.04(m,8H), 1.08-1.38(m,10H), 2.12-2.16(m,1H), 2.28-2.37(m,1H), 2.97-3.02(m ,1H), 4.14-4.30(m,4H).

preparation example 2

[0123] Preparation of 2-cyano-2-n-pentyl-3-isopropyl diethyl succinate: using the method of Preparation Example 1, replacing ethyl cyanoisovalerate with ethyl cyano-n-heptanoate to obtain 2 -Diethyl cyano-2-n-pentyl-3-isopropylsuccinate was rectified under reduced pressure to obtain 53.7g of the product (8mbar, 145-148°C). 1 H NMR (CDCl 3 / TMS,300MHz)δ(ppm):0.85-0.91(t,3H),0.97-1.10(m,6H),1.21-1.37(t,6H,m,4H),1.56-1.64(m,2H), 1.73-1.82 (t, 2H), 2.15-2.22 (m, 1H), 2.81-2.83 (d, 1H), 4.14-4.30 (m, 4H).

Embodiment 1

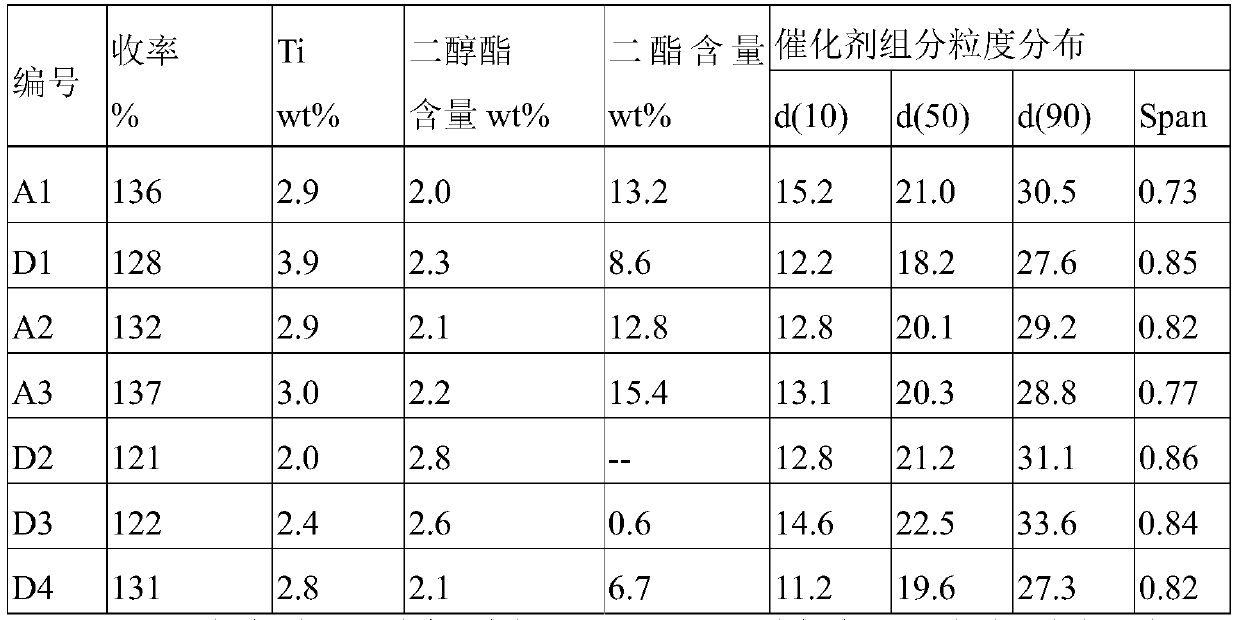

[0126] (1) Preparation of Catalyst Component A1

[0127] (1) In the reactor that has been repeatedly replaced with high-purity nitrogen, add 3.150mol (300.0g) of anhydrous magnesium chloride, 19.68mol (2.1L) of toluene, and 8.4mol (1.1L) of 2-ethylhexanol in sequence , under the conditions of a stirring speed of 450rpm and a temperature of 110°C, the reaction was carried out for 3.0 hours to obtain a stable and uniform alcoholate solution;

[0128] (2) Add 3,5-heptanediol dibenzoate 48mmol (24ml), diisobutyl phthalate 336mmol (90ml) and tetrabutyl titanate 132mmol (45ml) to the above alcoholate solution , stirred for 60 minutes, cooled to room temperature to obtain a homogeneous solution; the above homogeneous solution was added to fully replaced by nitrogen, and equipped with 60mol (6.6L) of titanium tetrachloride and 11.4mol (1.2L) of toluene at -20°C In the reactor, they were fully contacted at -20°C by stirring. After 5 hours, the temperature was raised to 100°C. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com