Yttrium oxide-tungsten continuous gradient material and preparation method thereof and application to high-temperature alloy smelting crucible manufacturing

A gradient material, yttrium oxide technology, applied in the field of materials, can solve the problems of reducing the thermal shock resistance of components, thermal stress mismatch, reducing the thermal mechanical properties of material components, etc., so as to improve the thermal shock resistance and high temperature mechanical properties. The effect of strong erosion ability, excellent mechanical properties and erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

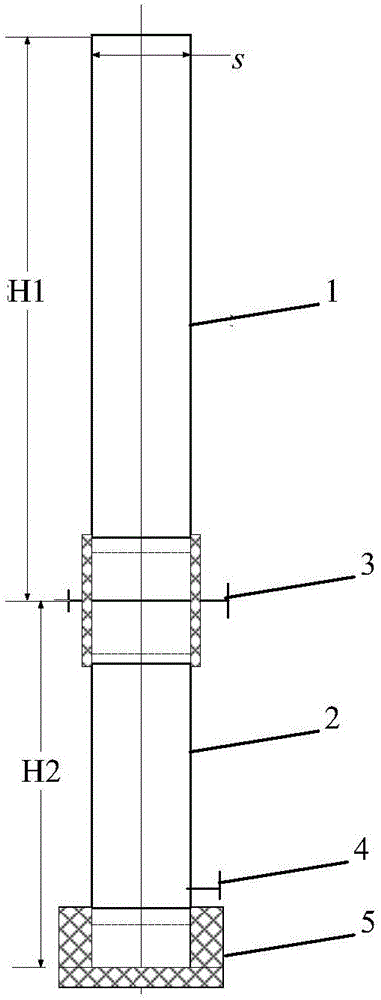

[0054] According to the preset l=1.0cm of the continuous gradient material, according to the formula and (wherein p=0.1), respectively weighed 1 part (parts by weight, the same below) of yttrium oxide powder with an average particle diameter of 1 μm and a purity of 98%, and 3.86 parts of tungsten powder with an average particle diameter of 2 μm and a purity of 98%. Water is selected as a solvent, polyethylene is used as a dispersant, water is used to prepare tungsten powder and yttrium oxide powder into a suspension, and the dispersant polyethylene is added so that its molar concentration in the dispersion is 0.5 mol%. The two dispersion liquids were respectively ultrasonically dispersed and stirred for 20 minutes to prepare dispersion liquids. use figure 1 The settling device is used for settling. During operation, the settling pipe 2 is filled with dispersion medium, the valve is closed, and the mold inserting section is put into the mold. Add the dispersion to be settl...

Embodiment 2

[0057] According to the preset l=2.0cm of the continuous gradient material, as in Example 1, according to the set formula, weigh 1 part of yttrium oxide powder with an average particle diameter of 1.5 μm and a purity of 98.5%, and the average particle diameter is 2 μm , 3.86 parts of tungsten powder with a purity of 98%, select ethanol as the solvent, polyacrylic acid as the dispersant, use water to prepare the tungsten powder and the yttrium oxide powder into a suspension, and add the dispersant polyacrylic acid to make it in the dispersion The molar concentration is 1mol%. The two dispersion liquids were respectively ultrasonically dispersed and stirred for 25 minutes to prepare dispersion liquids. use figure 1 The settling device is used for settling. During operation, the settling pipe 2 is filled with dispersion medium, the valve is closed, and the mold inserting section is put into the mold. Add the dispersion to be settled into the settling tube 1. After the dispersio...

Embodiment 3

[0060] As in Example 1, according to the set formula, l=1.0cm, weigh 1 part of yttrium oxide powder with an average particle diameter of 1.5 μm and a purity of 98.0%, and 3.86 tungsten powders with an average particle diameter of 2 μm and a purity of 98.5%. Parts, choose ethanol as solvent, PE as dispersant, as dispersant, use ethanol to prepare tungsten powder and yttrium oxide powder into suspension, and add dispersant PE so that its molar concentration in the dispersion is 1.5mol %. The two dispersion liquids were respectively ultrasonically dispersed and stirred for 20 minutes to prepare dispersion liquids. use figure 1 The settling device is used for settling. During operation, the settling pipe 2 is filled with dispersion medium, the valve is closed, and the mold inserting section is put into the mold. Add the dispersion to be settled into the settling tube 1. After the dispersion is stable, open the valve, and the particles will freely settle into the mold under the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com