Preparation method of fluorescent carbon quantum dots employing algae as carbon sources and application

A technology of carbon quantum dots and algae, which is applied in the field of preparing carbon quantum dot cell labeling probes with fluorescent properties, to achieve high added value, high product yield and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

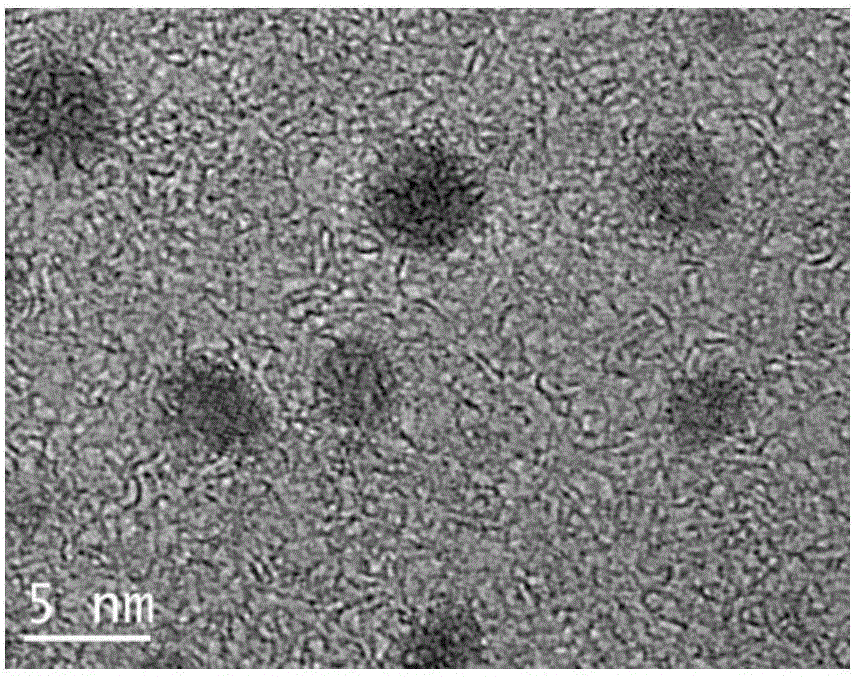

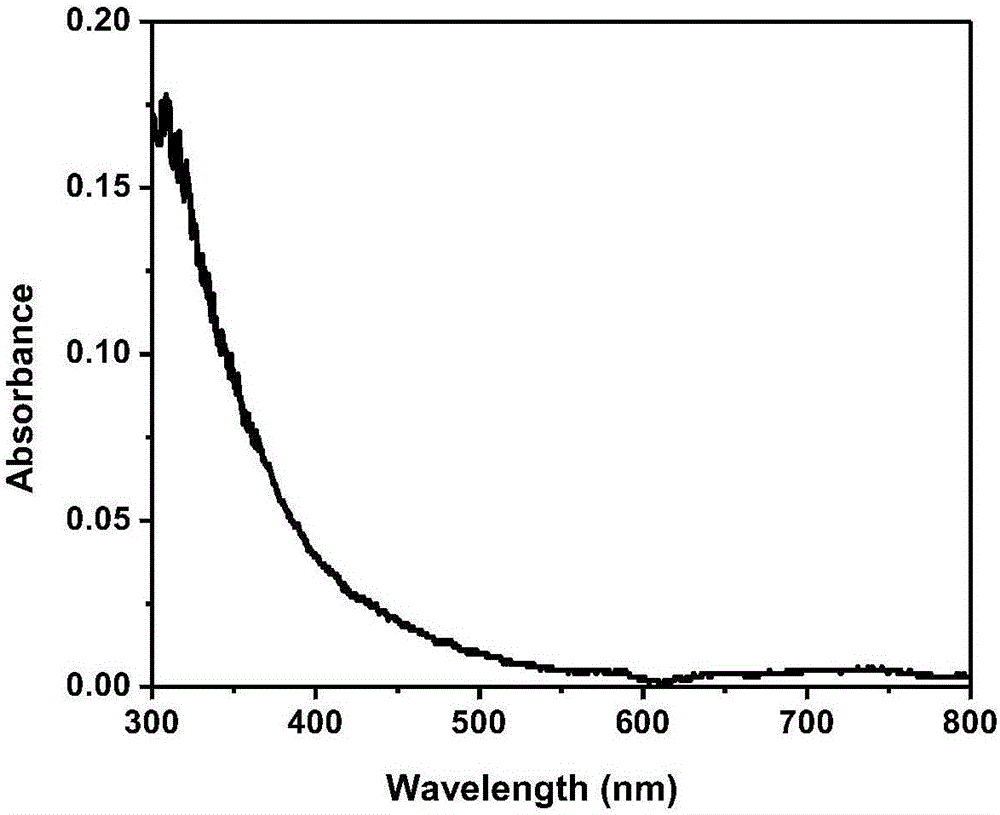

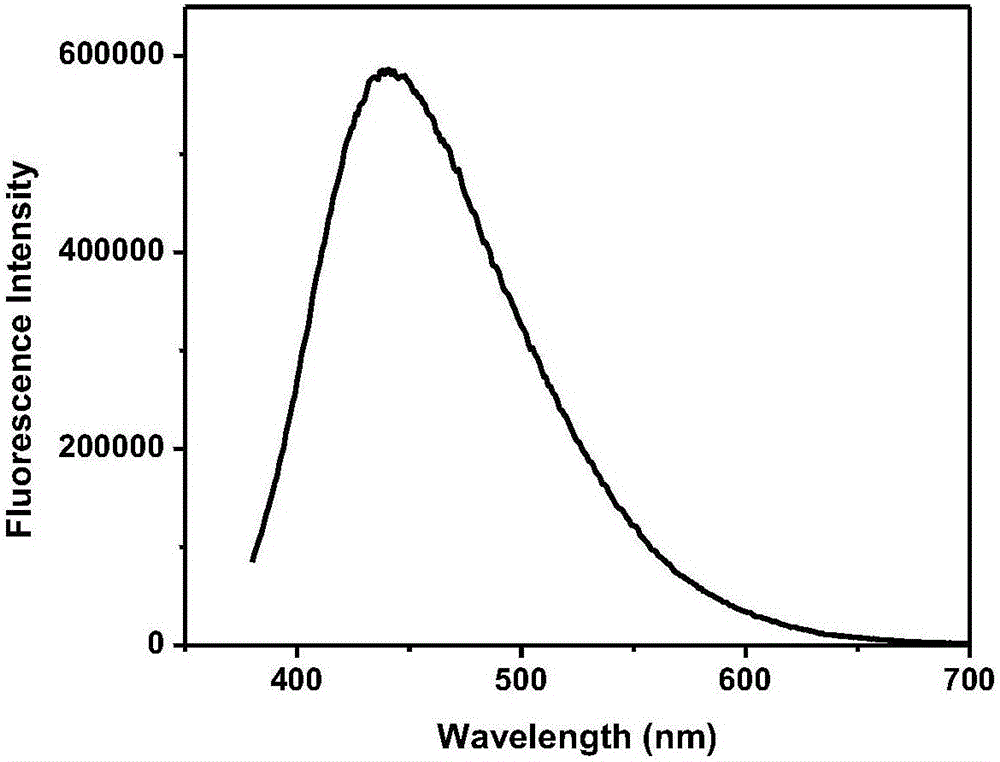

Image

Examples

Embodiment 1

[0032] (1) wash enteromorpha with tap water, remove impurities such as surface silt, then rinse with pure water;

[0033] (2) Weigh 200 grams of Enteromorpha raw material (about 10 grams in dry weight) after step (1), mix Enteromorpha and pure water according to the mass ratio of Enteromorpha and pure water, and put Tissue the raw material container of the mashing machine and pulverize for 5 minutes to obtain the enteromorpha slurry;

[0034] (3) Take by weighing 10 grams of Enteromorpha slurry that step (2) obtains, put into 30mL polytetrafluorohydrothermal reaction kettle and add a cover and put into the outsourcing sleeve to carry out airtight;

[0035] (4) Put the reaction kettle with Enteromorpha slurry into the microwave reactor, set the temperature to 200°C, and the pressure to 20atm, react for 60 minutes, then stop heating;

[0036] (5) When the temperature of the reactor is lowered to below 40°C, the lid of the reactor is opened, and the reaction product is a reddish...

Embodiment 2

[0041] (1) wash enteromorpha with tap water, remove impurities such as surface silt, then rinse with pure water;

[0042] (2) Weigh 200 grams of Enteromorpha raw material (about 10 grams in dry weight) after step (1), mix Enteromorpha and pure water according to the mass ratio of Enteromorpha and pure water, and put Pound the cup and pulverize for 5 minutes with a tissue masher to obtain Enteromorpha slurry;

[0043] (3) Take by weighing 30 grams of Enteromorpha slurry that step (2) obtains, put into 100mL polytetrafluorohydrothermal reaction kettle and add a cover and put into the outsourcing metal casing and carry out airtight;

[0044] (4) Put the reactor containing Enteromorpha slurry into an oven, set the temperature to 180°C, and react for 90 minutes. During the reaction, the temperature fluctuation is controlled at ±5°C, and then stop heating;

[0045] (5) When the temperature of the reactor is lowered to below 40°C, the lid of the reactor is opened, and the reaction p...

Embodiment 3

[0049] (1) wash enteromorpha with tap water, remove impurities such as surface silt, then rinse with pure water;

[0050] (2) Weigh 200 grams of Enteromorpha raw material (about 10 grams in dry weight) after step (1), mix Enteromorpha and pure water according to the mass ratio of Enteromorpha and pure water, and put Pound the cup and pulverize for 5 minutes with a tissue masher to obtain Enteromorpha slurry;

[0051] (3) Take by weighing 30 grams of Enteromorpha slurry that step (2) obtains, put into 100mL polytetrafluorohydrothermal reaction kettle and add a cover and put into the outsourcing metal casing and carry out airtight;

[0052] (4) Put the reaction kettle with Enteromorpha slurry into the muffle furnace, set the temperature to 200°C, and react for 60 minutes. During the reaction, the temperature fluctuation is controlled at ±5°C, and then stop heating;

[0053] (5) When the temperature of the reactor is lowered to below 40°C, the lid of the reactor is opened, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com