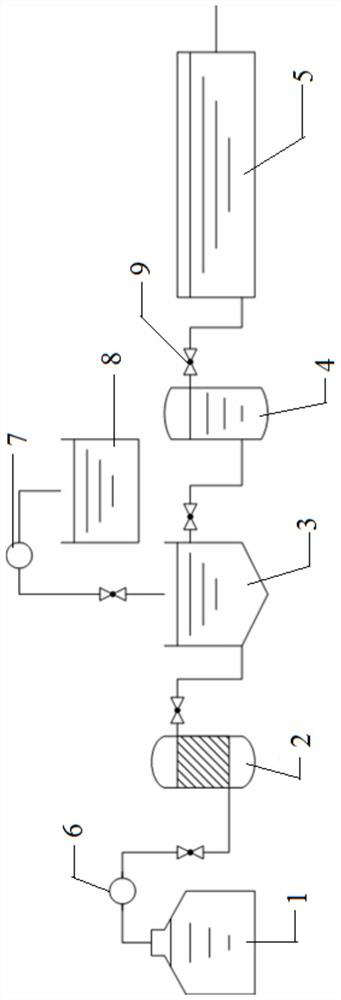

A treatment system, treatment method and application of coking phenol cyanide wastewater

A treatment system and treatment method technology, applied in the treatment system of coking cyanide wastewater, using advanced catalytic oxidation technology for advanced treatment of coking phenol cyanide wastewater, can solve the problems of high wastewater treatment cost and weak wastewater treatment capacity, etc. Achieve long service life, strong reliability and differentiability, reduce organic matter and ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

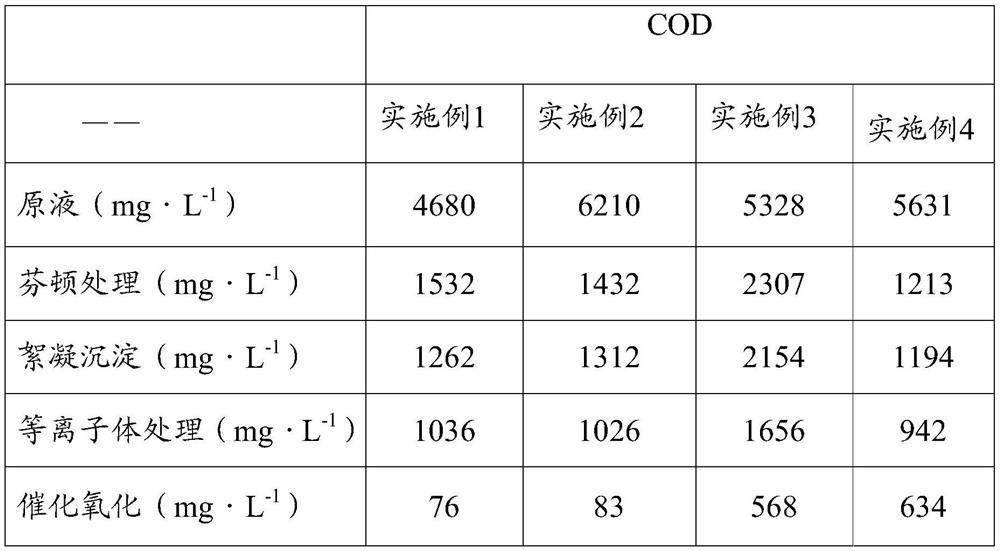

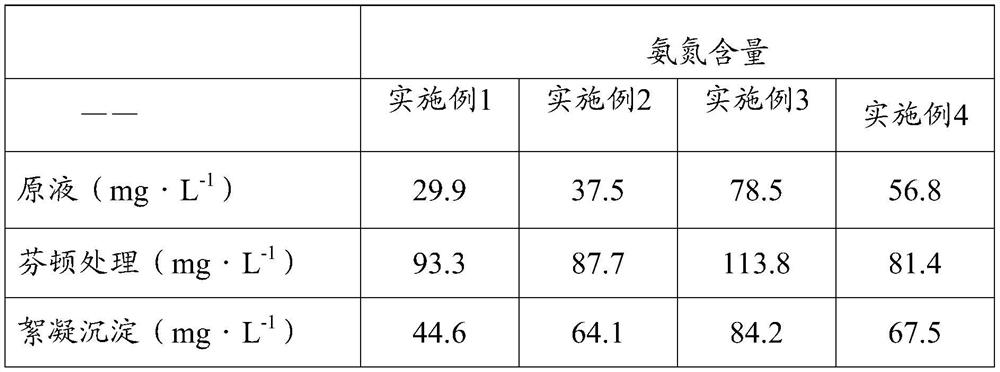

Embodiment 1

[0063] Embodiment one provides a kind of method that coking phenol cyanide wastewater is carried out advanced treatment, and treatment method is as follows:

[0064] (1) Acidification treatment: Pass 4000mL of phenol cyanide wastewater with COD and ammonia nitrogen contents of 4680mg / L and 29.9mg / L respectively into the acidification tank, and add concentrated sulfuric acid with a mass fraction of 98.3% therein for acidification, and fully stir Afterwards, the pH value of the waste water is 2 to 3;

[0065] (2) Fenton reaction: solution after acidification is passed into Fenton tower, and add ferrous salt and hydrogen peroxide, wherein hydrogen peroxide: coking phenol cyanide waste water=15mL: 1L, ferrous sulfate: coking phenol cyanide waste water=1.5g : 1L, the reaction is carried out under normal pressure, the reaction temperature is 65°C (the raw water inlet temperature after ammonia distillation), and the reaction time is 1.5 hours. After the Fenton reaction occurs, a larg...

Embodiment 2

[0077] Embodiment two provides a kind of method that coking phenol cyanide waste water is carried out advanced treatment, and treatment method is as follows:

[0078] (1) Pass 4000mL COD and ammonia nitrogen content of 6210mg / L and 37.5mg / L phenol cyanide wastewater into the acidification tank, and dropwise add concentrated sulfuric acid with a mass fraction of 98.3% for acidification, and the pH value of the wastewater after fully stirring 2 to 3;

[0079](2) Pass the acidified solution into Fenton tower, and add ferrous salt and hydrogen peroxide, wherein hydrogen peroxide: coking phenol cyanide wastewater=15mL: 1L, ferrous sulfate: coking phenol cyanide wastewater=1.5g: 1L, the reaction Under normal pressure, the reaction temperature is 65 °C, and the reaction time is 1.5 hours. After the Fenton reaction occurs, a large number of hydroxyl radicals are generated in the solution, and some organic substances are oxidized to inorganic substances and organic acids;

[0080] (3)...

Embodiment 3

[0086] Adjust the amount of Fenton reaction agent, calcium oxide and sodium hydroxide after the Fenton reaction in Example 1, replace the flocculant with aluminum sulfate and polyferric sulfate, and replace hydrogen peroxide with heavy weight in the electrochemical catalytic oxidation process simultaneously. Potassium chromate, coking phenol cyanide wastewater for advanced treatment, the specific treatment methods are as follows:

[0087] (1) Pour 4000 mL of phenolic cyanide wastewater with COD and ammonia nitrogen contents of 5328 mg / L and 78.5 mg / L into the acidification tank, and dropwise add concentrated sulfuric acid with a mass fraction of 98.3% in it for acidification. After thorough stirring, the pH value of the wastewater is is 2.5;

[0088] (2) Pass the acidified solution into Fenton tower, and add ferrous salt and hydrogen peroxide, wherein hydrogen peroxide: coking phenol cyanide wastewater=5mL: 1L, ferrous sulfate: coking phenol cyanide wastewater=0.5g: 1L, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com