Method for treating high-salt organic wastewater

A technology for organic wastewater and wastewater, applied in separation methods, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as lack of effective treatment methods, and achieve the effects of less impurities, high purity, and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

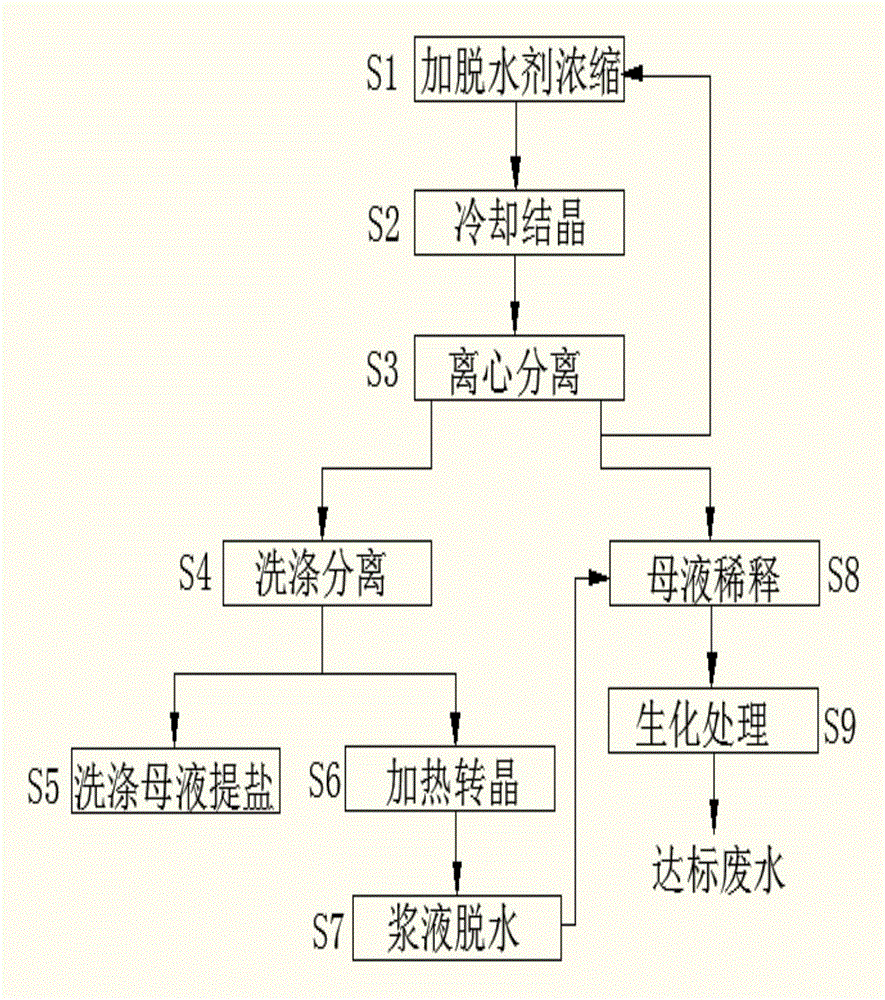

Image

Examples

Embodiment 1

[0044] Embodiment 1: Wastewater treatment method with high content of organic matter and sodium chloride:

[0045] 1 ton of wastewater discharged from casing production contains 80kg of sodium chloride and 100kg of organic matter.

[0046] The first concentrated salt extraction: heat the wastewater to 65°C, add 276kg of sodium carbonate to the water until the wastewater is saturated; cool down to -5°C, and precipitate 680kg of sodium carbonate decahydrate crystals and 72kg of sodium chloride crystals; Centrifuge to obtain 492kg of mixed salt crystals and high-organic concentrated mother liquor (containing 24kg sodium carbonate, 8kg sodium chloride); use 2°C saturated aqueous solution of sodium carbonate as washing liquid to wash the mixed salt crystals, and remove the chloride in the crystals. Sodium is dissolved in the washing mother liquor to obtain sodium carbonate decahydrate crystals and washing mother liquor; the washing mother liquor is heated to 95°C, evaporated and co...

Embodiment 2

[0052] Embodiment 2: Wastewater treatment method with high content of organic matter and magnesium chloride:

[0053] 1.5t of wastewater discharged from dye production contains 60kg of magnesium chloride and 120kg of refractory organic matter.

[0054] Concentration and salt extraction for the first time: heat the wastewater to 60°C, add 543kg of magnesium sulfate monohydrate solid to the water until the wastewater is saturated; cool down to -5°C, and precipitate 964.4kg of magnesium sulfate heptahydrate crystals and 72.5kg of magnesium chloride hexahydrate; The crystallization wastewater is centrifuged to obtain 1016.6 kg of mixed salt crystals and concentrated mother liquor with high organic content (containing 1.74 kg of magnesium sulfate and 26 kg of magnesium chloride); use 3° C. saturated aqueous solution of magnesium sulfate as washing liquid to wash the mixed salt crystals, and the crystals Magnesium chloride in the solution is dissolved in the washing mother liquor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com