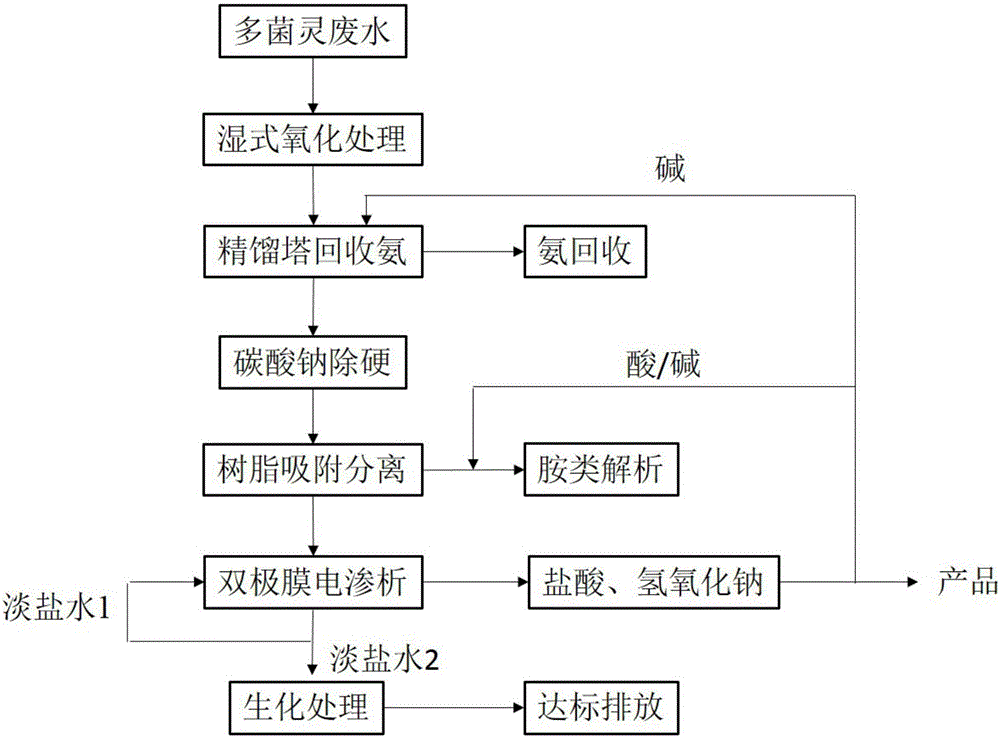

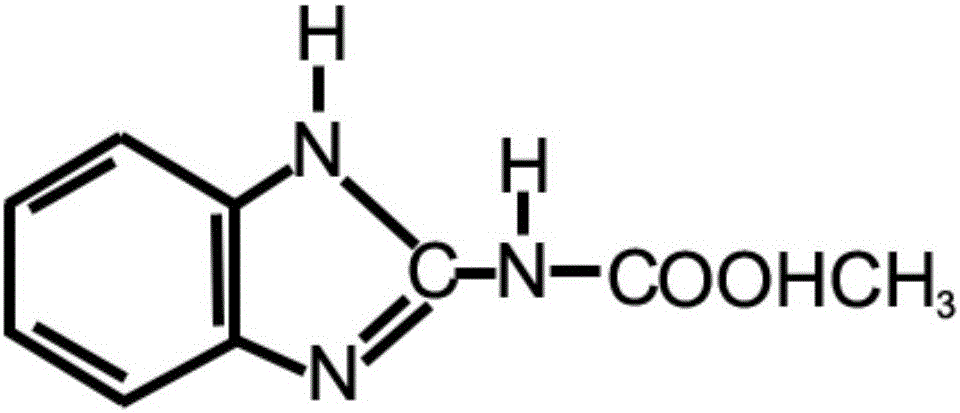

Resource treatment method of carbendazol production wastewater

A technology for producing wastewater and treatment methods, which is applied in the fields of natural water treatment, chemical instruments and methods, and multi-stage water/sewage treatment. pressure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Wet oxidation: Take 100ml of waste water and put it into a 500ml high-pressure reactor, add 0.5g of copper sulfate, seal it, keep the pressure at 0.8MPa, then raise the temperature to 200°C, react for 2h, cool, and cool down to obtain an oxidation post-treatment solution. The detected COD dropped from 46500mg / L to 8118mg / L.

[0034] (2) After the wet oxidation treatment, the pH of the waste water is adjusted by adding sodium hydroxide to 11.0, and then it is sent to rectification and deamination. The sodium hydroxide is the sodium hydroxide that reclaims and obtains in the bipolar membrane electrodialysis process in the step (5).

[0035] (3) After adding 28g of sodium carbonate to remove hardness, the hardness in the wastewater was reduced from 26600mg / L to 60mg / L.

[0036] (4) Adopt macroporous resin to adsorb and remove amines in the waste water, and characterize it with COD. The COD concentration is reduced from 8000mg / L to 3160mg / L, and the acid-base recovered...

Embodiment 2

[0042] (1) Wet oxidation: Take 500ml of waste water and put it into a 1000ml autoclave, add 2.5g of copper sulfate, seal it, keep the pressure at 0.8MPa, then raise the temperature to 200°C, react for 2h, cool, and lower the temperature to obtain the post-oxidation treatment liquid, which is tested COD dropped from 46500mg / L to 8008mg / L.

[0043] (2) After the wet oxidation treatment, adding sodium hydroxide to the water to adjust the pH of the waste water is 11.0, and then sending it into the rectification deamination, the residual liquid ammonia nitrogen concentration in the detection kettle is 600.4mg / L, and the total nitrogen concentration is 2583mg / L; The sodium hydroxide is the sodium hydroxide that reclaims and obtains in the bipolar membrane electrodialysis process in the step (5).

[0044] (3) After adding 28g of sodium carbonate to remove hardness, the hardness in the wastewater was reduced from 26600mg / L to 40mg / L.

[0045] (4) Use macroporous resin to adsorb and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com