Liquid fertilizer for water culture of cucumber

A hydroponics and cucumber technology is applied in the field of liquid fertilizer to achieve the effect of increasing activity, comprehensive nutrients and promoting vegetable growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

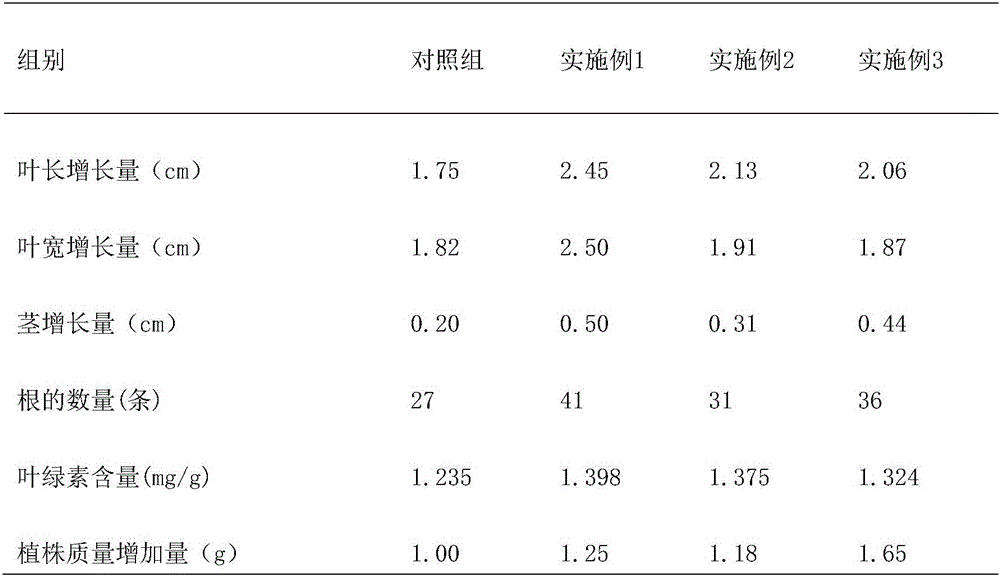

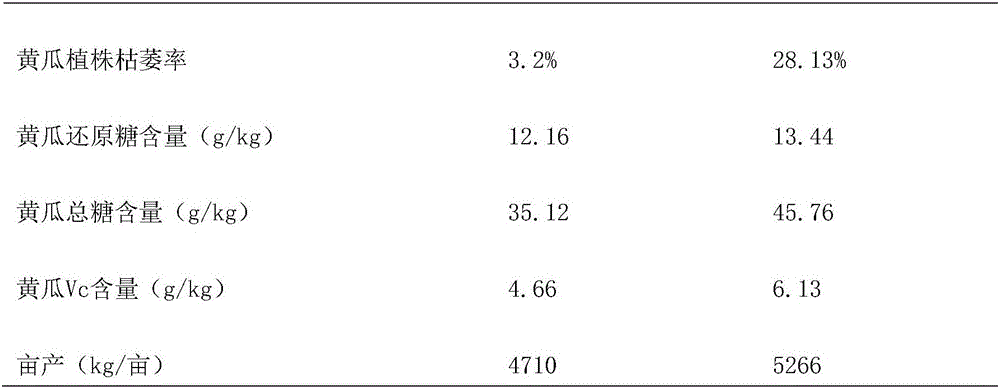

Examples

Embodiment 1

[0023] A kind of hydroponic cucumber liquid fertilizer, raw material weight part consists of

[0024] Sodium acetate 20g, sodium carbonate 12g, sodium thiosulfate 8g, sodium chloride 6g, magnesium sulfate 2g, urea phosphate 1g, potassium chloride 1g, yeast extract 4g, water 95ml, photosynthetic bacteria suspension 1ml.

[0025] Its preparation method is:

[0026] (1) Take 20g of sodium acetate, 12g of sodium carbonate, 8g of sodium thiosulfate, 6g of sodium chloride, 2g of magnesium sulfate, 1g of urea phosphate, 1g of potassium chloride, and 4g of yeast extract in parts by weight, mix the above raw materials, and add the purified 100ml of water, adjust the pH to 7.3, put it into a homogeneous equipment to prepare a homogeneous suspension, put the suspension into a sterilizer and keep it at 130°C for 140min for high-temperature sterilization, as the inoculum for the next step.

[0027] (2) Cool the inoculum to 32° C., and inoculate 1 ml of photosynthetic bacteria suspension; ...

Embodiment 2

[0031] A kind of hydroponic cucumber liquid fertilizer, raw material weight part consists of

[0032] Sodium acetate 25g, sodium carbonate 13g, sodium thiosulfate 5g, sodium chloride 4g, magnesium sulfate 4g, urea phosphate 2g, potassium chloride 3g, yeast extract 7g, water 100ml, photosynthetic bacteria suspension 2ml.

[0033] Its preparation method is:

[0034] (1) Take 25g of sodium acetate, 13g of sodium carbonate, 5g of sodium thiosulfate, 4g of sodium chloride, 4g of magnesium sulfate, 2g of urea phosphate, 3g of potassium chloride, and 7g of yeast extract in parts by weight, mix the above raw materials, and add the purified 100ml of water, adjust the pH to 7.5, put it into a homogeneous equipment to prepare a homogeneous suspension, put the suspension into a sterilizer and keep it at 120°C for 100min for high-temperature sterilization, as the inoculum for the next step.

[0035] (2) Cool the inoculum to 31° C., and inoculate 2 ml of photosynthetic bacteria suspension;...

Embodiment 3

[0039] A kind of hydroponic cucumber liquid fertilizer, raw material weight part consists of

[0040] Sodium acetate 15g, sodium carbonate 10g, sodium thiosulfate 10g, sodium chloride 3g, magnesium sulfate 5g, urea phosphate 3g, potassium chloride 3g, yeast extract 2g, water 93ml, photosynthetic bacteria suspension 0.5ml.

[0041] Its preparation method is:

[0042] (1) Take 15g of sodium acetate, 10g of sodium carbonate, 10g of sodium thiosulfate, 3g of sodium chloride, 5g of magnesium sulfate, 3g of urea phosphate, 3g of potassium chloride, and 2g of yeast extract in parts by weight, mix the above raw materials, and add the purified Water 93ml, adjust the pH to 7.4, put it into a homogeneous equipment to prepare a homogeneous suspension, put the suspension into a sterilizer and keep it at 125°C for 130min for high-temperature sterilization, as the inoculum for the next step.

[0043] (2) Cool the inoculum to 31° C., and inoculate 0.5 ml of photosynthetic bacteria suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com