Device and method for increasing yield of tar by using coke oven gas as raw material through catalytic reforming

A coke oven gas and catalytic reforming technology, which is applied in coking ovens, petroleum industry, and the preparation of liquid hydrocarbon mixtures, etc., can solve the problem of high cost of preparation sources, and achieve the effects of reducing greenhouse effect, production cost, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

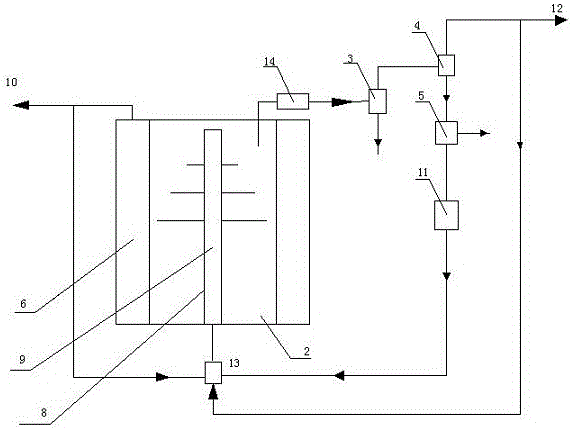

Method used

Image

Examples

Embodiment 1

[0052] Pyrolysis under N2 atmosphere

[0053] Coal of a certain size is pyrolyzed within the temperature range of 500°C-1100°C, the pressure is normal pressure, the residence time is 1 hour, and the nitrogen flow rate is 600ml / min. The tar yields at 500°C, 600°C, 700°C, 800°C, and 900°C were 4.17%, 4.14%, 4.46%, 4.63%, and 4.52%, respectively.

Embodiment 2

[0055] Pyrolysis under mixed atmosphere of coke oven gas, combustion waste gas and water vapor

[0056] Coal of a certain size is pyrolyzed within the temperature range of 500°C-1100°C, the pressure is normal pressure, the residence time is 1 hour, and the flow rate of coke oven gas, combustion exhaust gas and water vapor mixture is 600ml / min. The tar yields at 500°C, 600°C, 700°C, 800°C, and 900°C were 4.35%, 4.63%, 5.06%, 4.74%, and 4.63%, respectively.

Embodiment 3

[0058] Ni / Al 2 o 3 Catalytic activation of mixed gas pyrolysis

[0059] The selected catalyst is Ni / Al 2 o 3, Coal of a certain size is pyrolyzed within the temperature range of 500°C-1100°C, the pressure is normal pressure, the residence time is 1 hour, and the mixed gas flow rate is 600ml / min. The tar yields at 500°C, 600°C, 700°C, 800°C, and 900°C were 3.49%, 3.56%, 4.96%, 4.68%, and 4.71%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com